A process flow method for embedded groove anti-corrosion

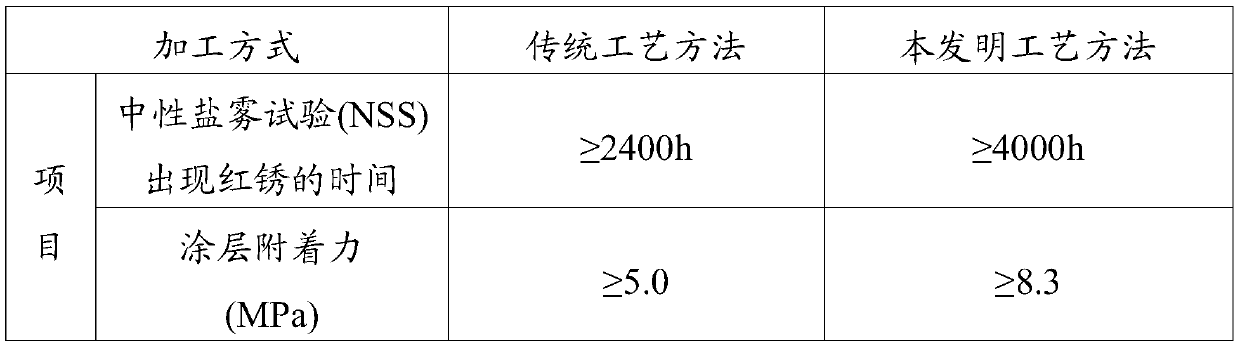

A technology of process flow and pre-embedded groove, which is applied in the direction of anti-corrosion coating, metal material coating technology, solid-state diffusion coating, etc., can solve the problems of complex processing, high cost of materials and processing, easy collision and entanglement, etc. Achieve the effect of reducing production cost, excellent anti-corrosion effect, and ensuring anti-corrosion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: A process flow method for embedded groove anti-corrosion, comprising the following steps:

[0020] (1) Weld the anchor rod on the back of the channel;

[0021] (2) Perform shot blasting treatment on the pre-buried channel of the welded anchor rod to remove surface corrosion;

[0022] (3) The pre-embedded tank is treated at a high temperature of 400°C to remove the oil on the surface;

[0023] (4) Put the pre-embedded tank with clean surface treatment into the multi-component alloy co-infiltration furnace, heat it to above 500°C and keep it warm for 6 hours to form a multi-component alloy anti-corrosion protective coating on the metal surface;

[0024] (5) Take out the pre-buried tank, wait for it to cool down, and carry out surface soot blowing treatment;

[0025] (6) The arc is formed by the arc bending machine and calibrated to the corresponding radian;

[0026] (7) Soak the arc-shaped pre-embedded groove in antiseptic solution, take it out, hang it and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com