Pile driver drill bit for completing hard rock and soil layer drilling and filling in one step

A rock-soil layer and hard technology, applied in the field of construction engineering pile drivers, can solve the problems of low construction efficiency, complex construction process and high piling cost, and achieve the effects of convenient opening, reasonable conception and high use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

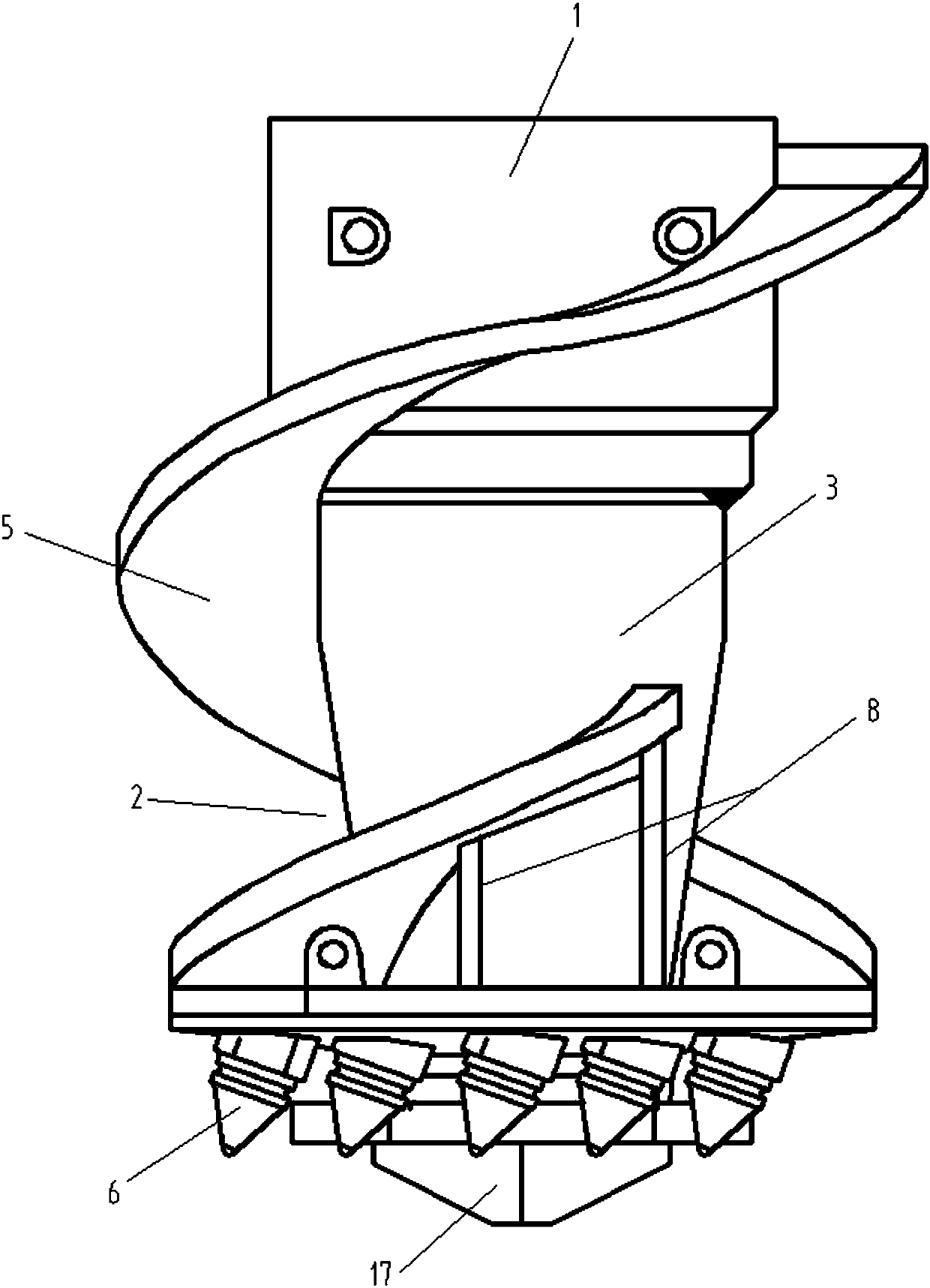

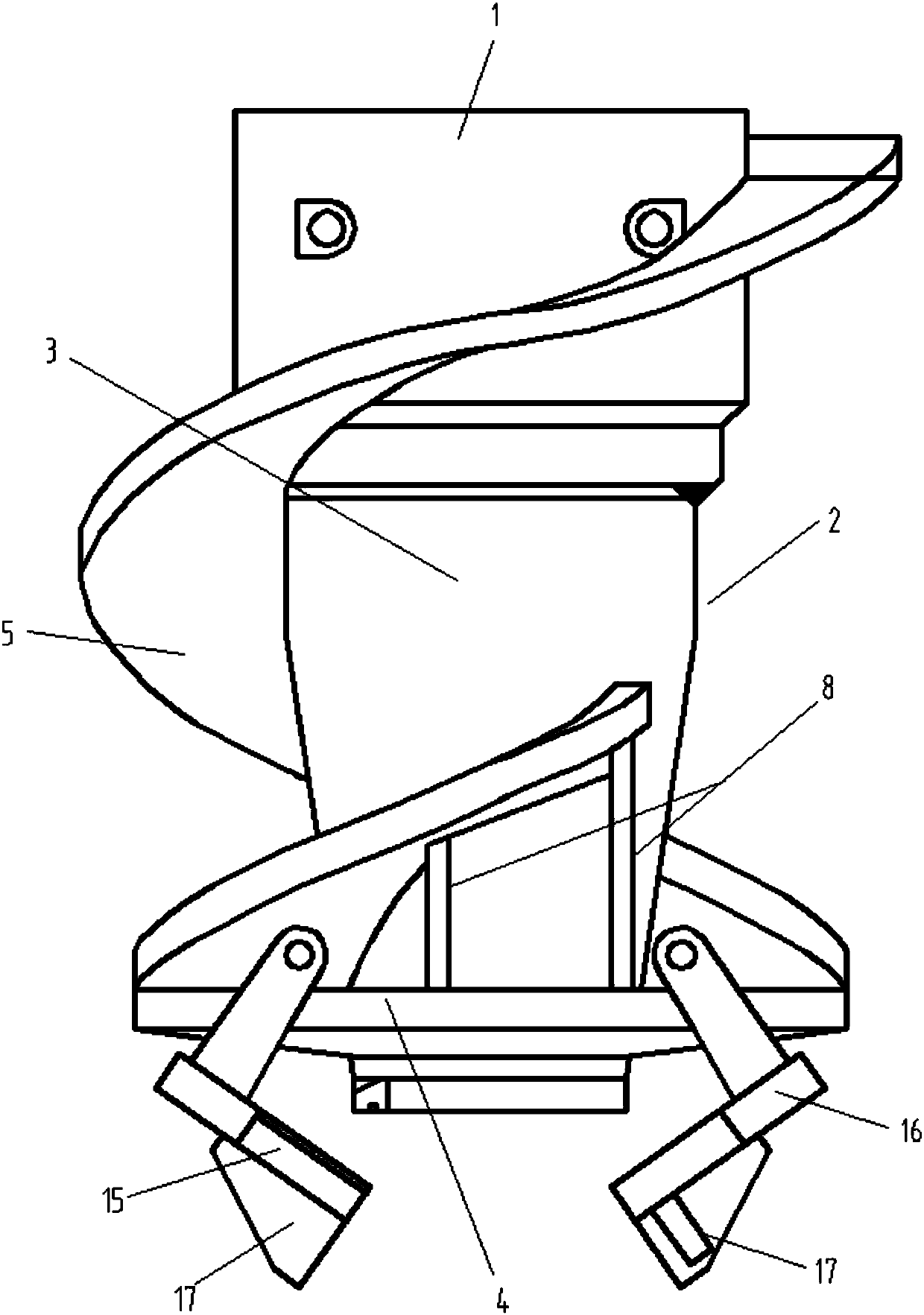

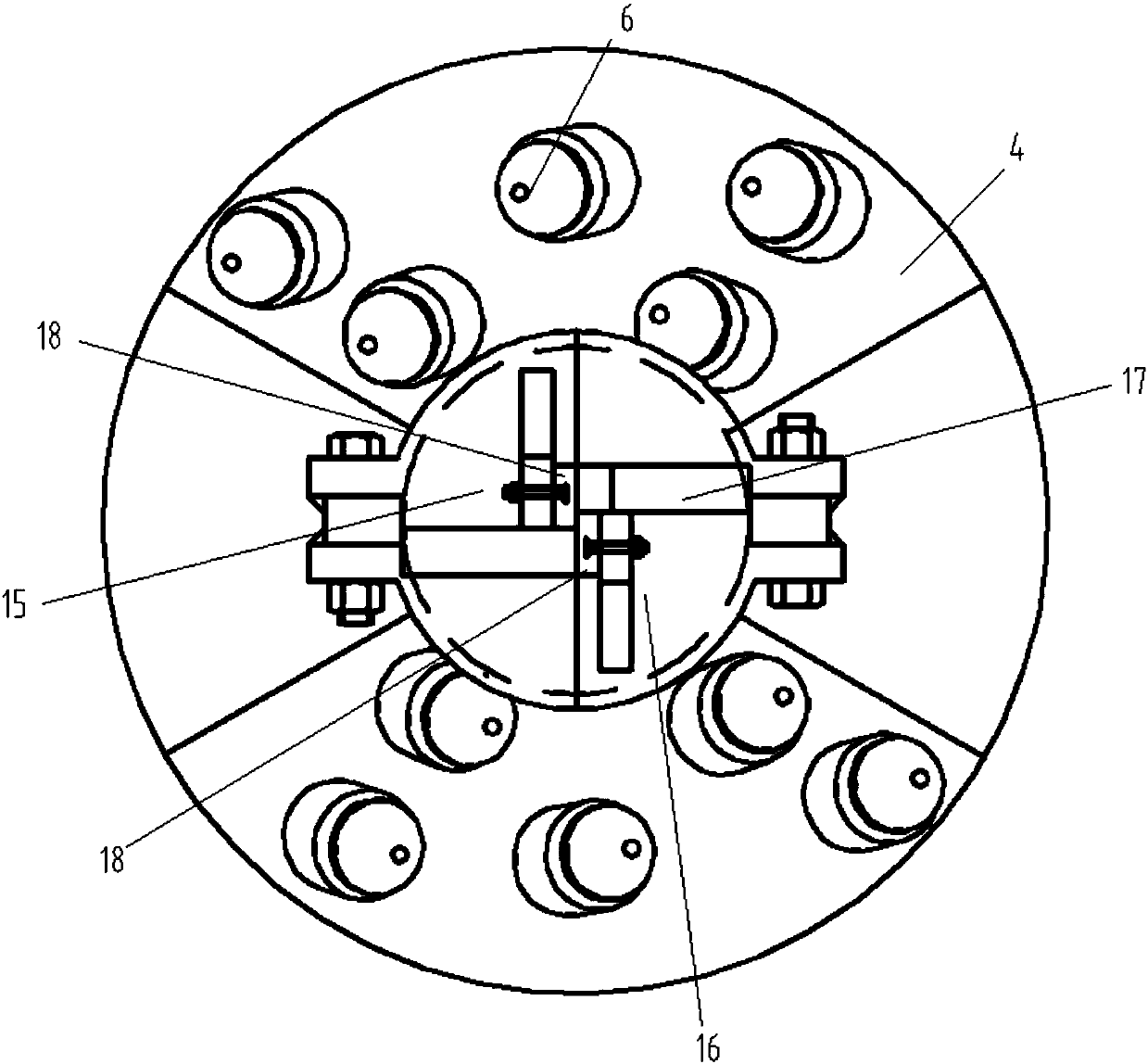

[0026] Attached below Figure 1-6 A first embodiment of the present invention will be described.

[0027] A pile driver drill bit used for drilling and pouring in hard rock and soil layer at one time, has a drill bit body 2, and the drill bit body 2 includes a drill pipe joint 1, an outer pipe body 3, a mounting part 4, a helical blade 5 and a pick 6 , the upper end of the outer pipe body 3 is fixedly connected to the lower end of the drill pipe joint 1 and the helical blade 5 is arranged on the outer circumferential wall of the drill pipe joint 1 and the outer pipe body 3, and the mounting part 4 is arranged on the outer wall of the lower end of the outer pipe body 3 On the mounting part 4, a plurality of picks 6 located on both sides of the outer tube body 3 are provided, and the other two sides of the lower end of the outer tube body 3 are provided with automatic openings for connecting or disconnecting the inside of the outer tube body 3 with the outside world. type drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com