Driving device for double-wheel slot milling machine slush pump

A technology of driving device and mud pump, which is applied to components of pumping devices for elastic fluids, machines/engines, pumps, etc. It can solve problems such as high processing accuracy, inconvenient installation and debugging, and compact and complex structure. Achieve the effect of reducing the difficulty and cost of later maintenance, improving the service life and breaking through the technical blockade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

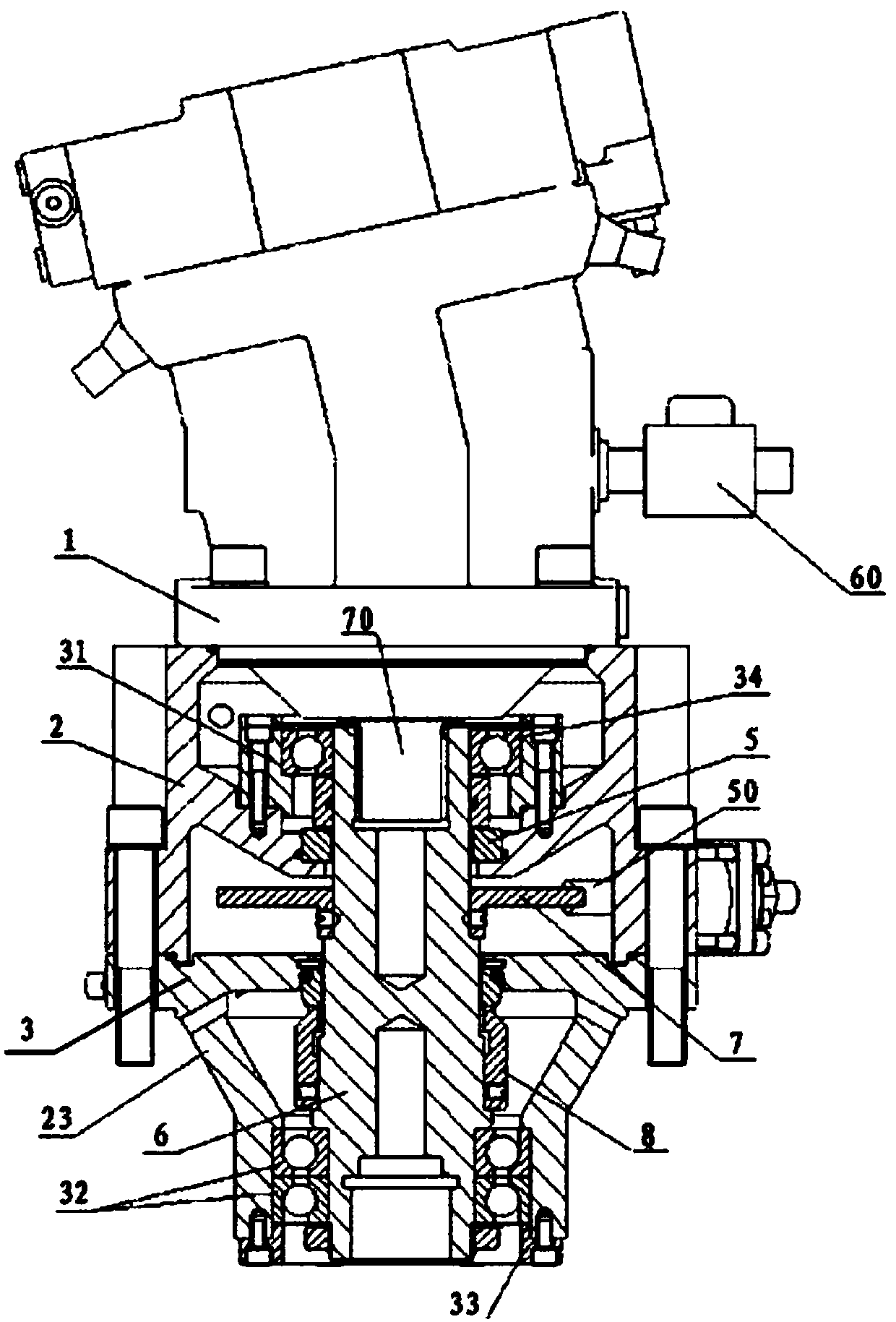

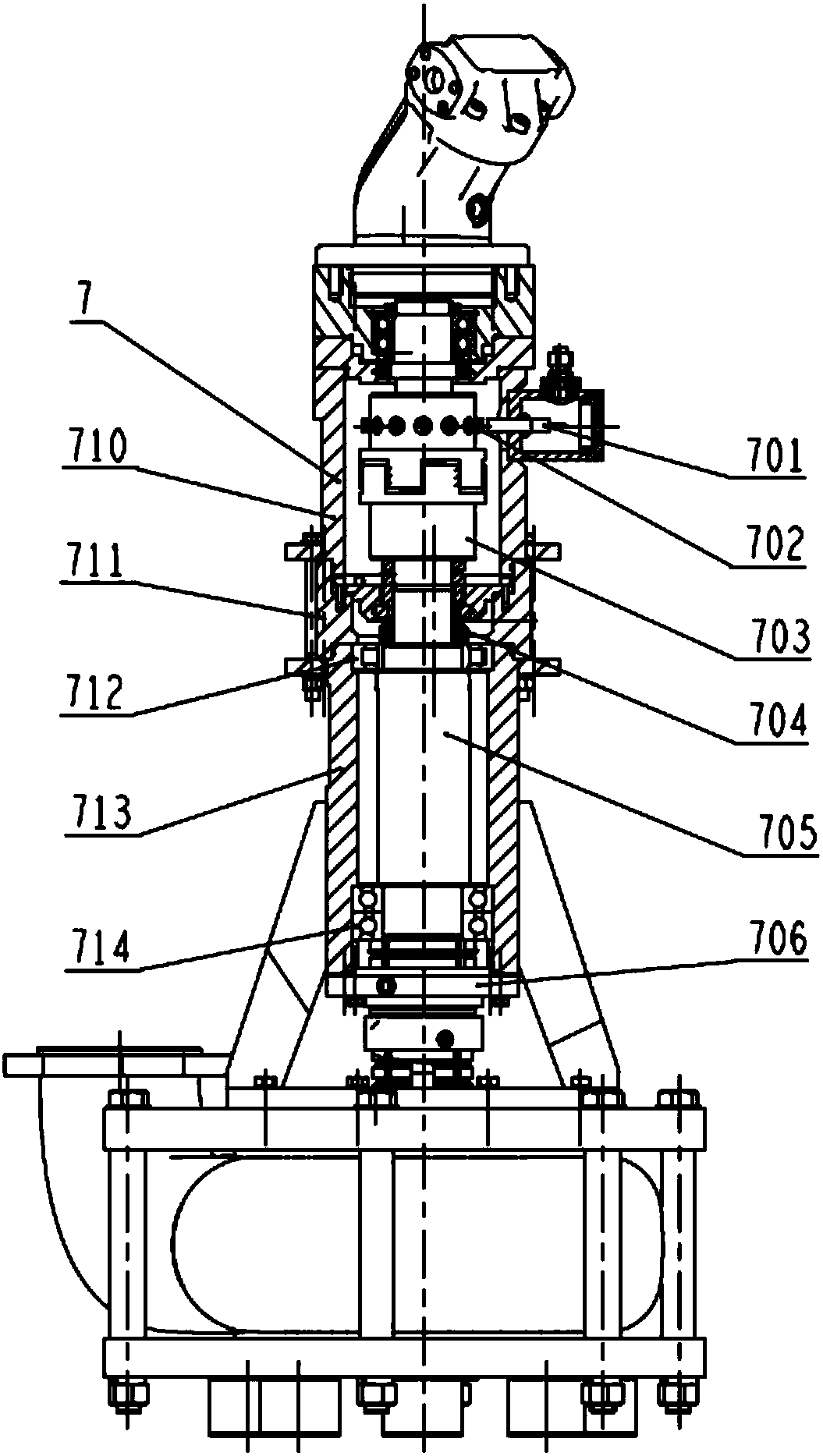

[0035] refer to Figure 4 , The base 3 of the motor mount 2 is also provided with an oil discharge port 302, the oil discharge port 302 is detachably provided with a closing mechanism, and the oil discharge port communicates with the first closed cavity. The oil discharge port is in a closed state at ordinary times, and when the motor is disassembled, the hydraulic oil in the first closed cavity can be discharged through the oil discharge port.

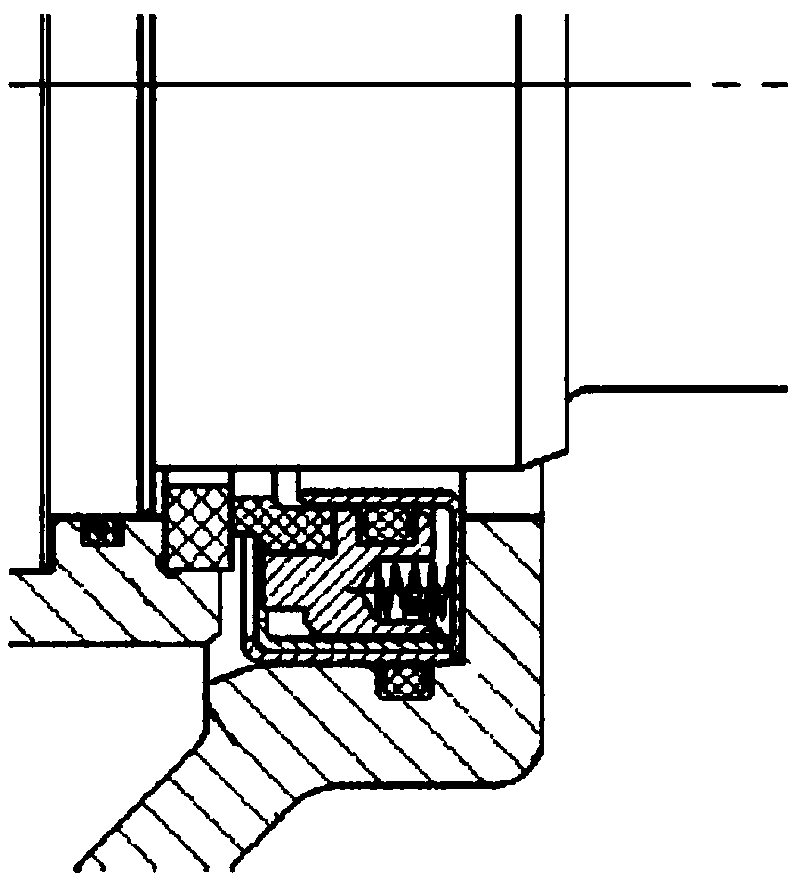

[0036] refer to image 3 and Figure 4 , the upper end of the transmission shaft 4 is installed in the inner cavity of the motor mount 2 through the first bearing 6 . When the present invention is working, the hydraulic oil leaked from the motor flows through the first bearing 6 and then flows to the first sealing assembly 5, which can cool the temperature rise of the bearing and sealing assembly during operation and prolong the working life of the bearing and sealing assembly. The first bearing 6 adopts paired bearings, which are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com