Low nitrogen cyclone gas burner with gas-air accurate classification function and internally provided with flue gas recirculation channels

A flue gas recirculation and gas burner technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of complex structure of external flue gas recirculation, and the economy is not as good as built-in flue gas recirculation, etc. To achieve the effect of reducing concentration, improving combustion conditions and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

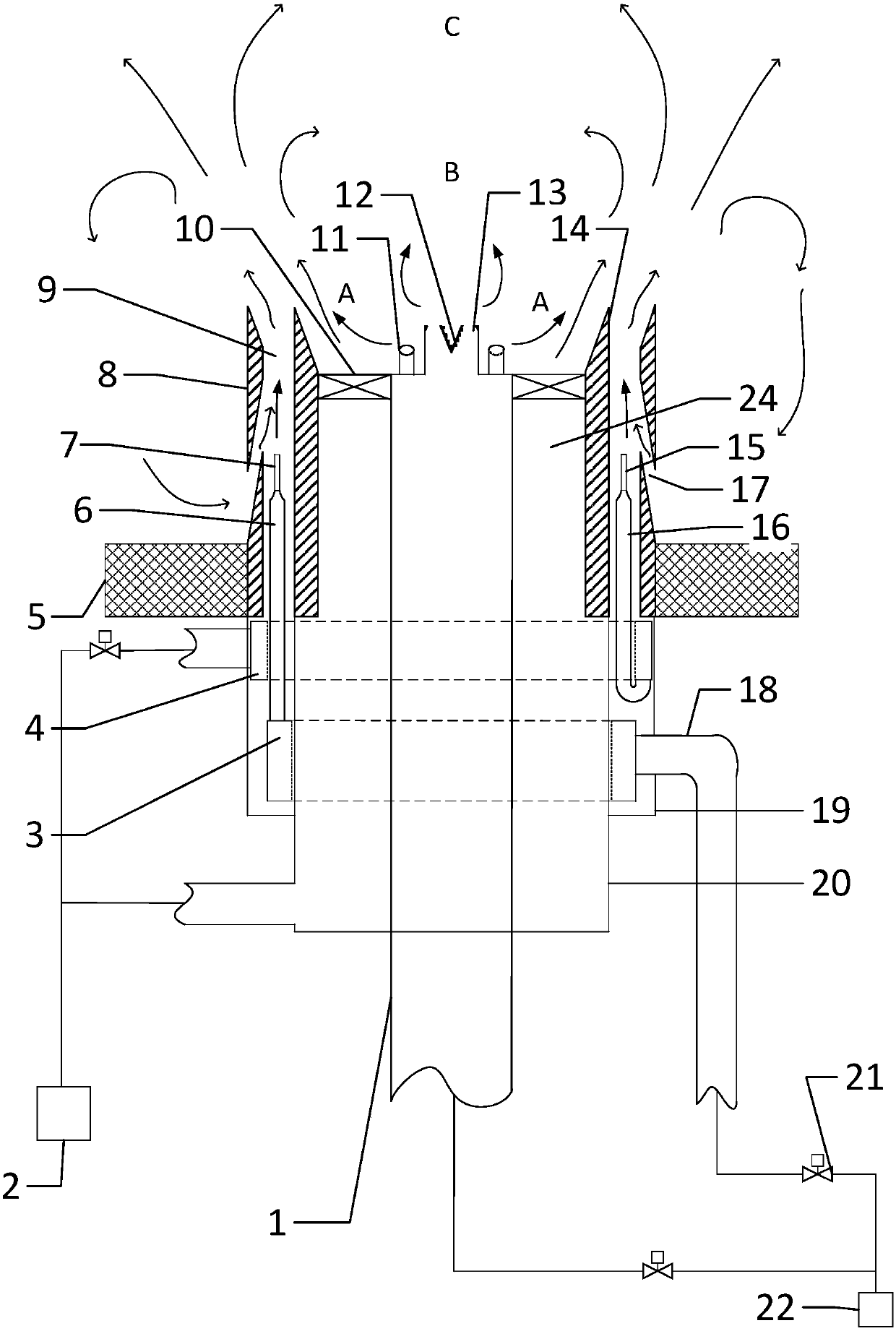

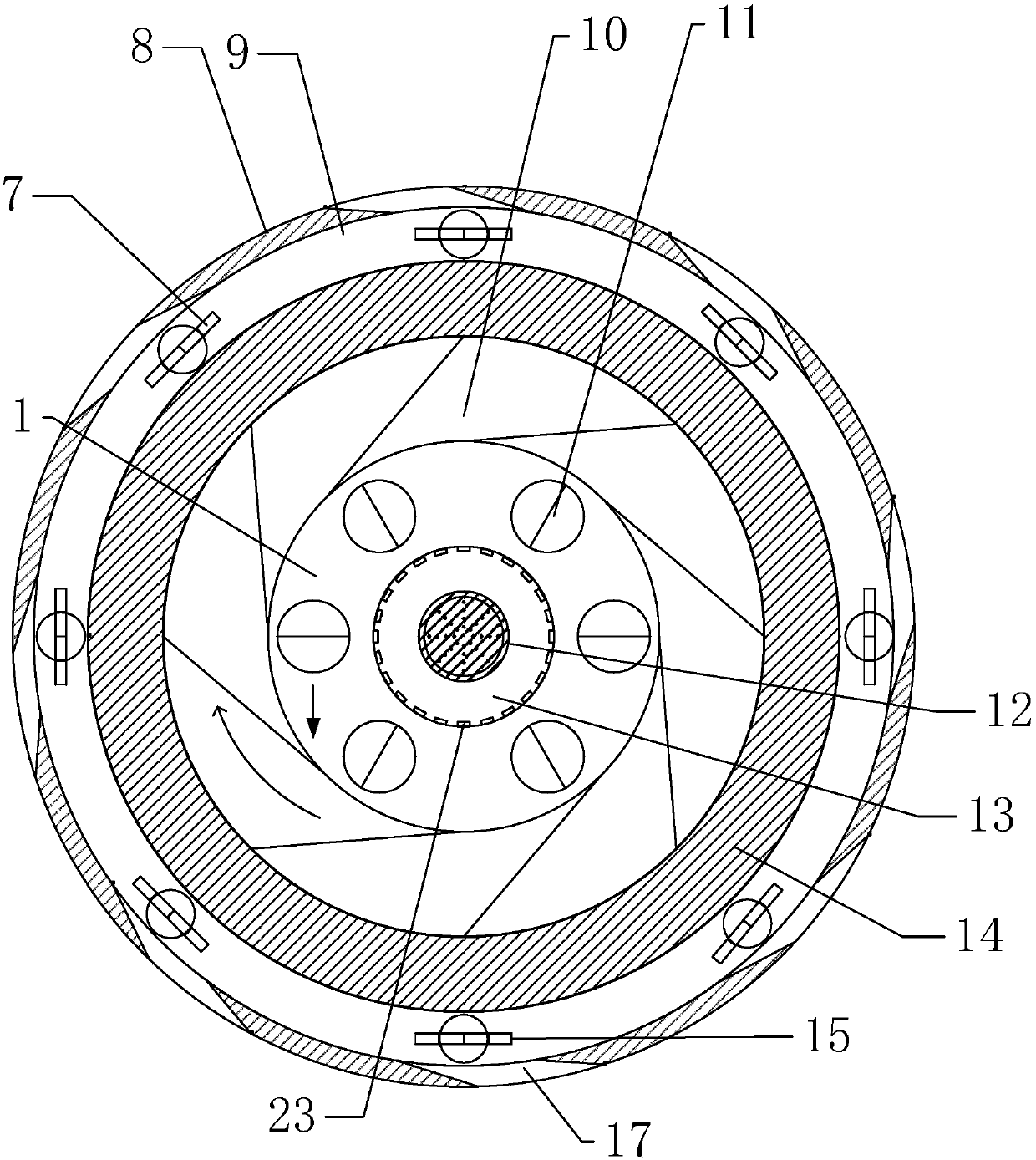

[0035] see Figure 1 to Figure 5(b) , the present invention includes a furnace, a furnace wall 5, and a central fuel delivery pipe 1, a primary air passage 24 and a mixing passage 9 that are sequentially sleeved from the inside to the outside. Pass furnace wall 5 and stretch in the furnace.

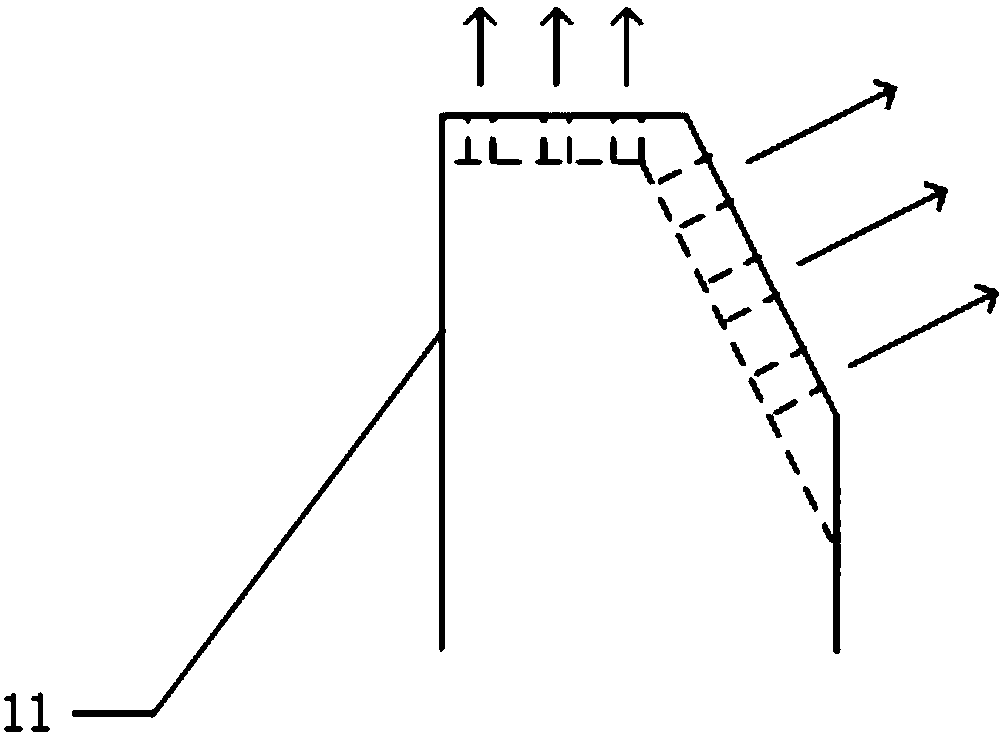

[0036] A central fuel nozzle 13 and several secondary fuel nozzles 11 are arranged at the front end of the central fuel delivery pipe 1; several tertiary fuel guns 6 and secondary air spray guns 16 are arranged at intervals and evenly in the mixing channel 9 . The tertiary fuel gun 6 is connected to the tertiary fuel delivery pipeline 18 through the annular tertiary fuel header 3, and the fuel is uniformly supplied by the tertiary fuel annular header 3, and the central fuel delivery pipeline 1 and the tertiary fuel delivery pipeline 18 pass through The valve 21 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com