Method of non-destructive testing of peak value voltage of infrared detector

An infrared detector and peak voltage technology, which is applied in the field of photoelectric detection, can solve the problems of sensitive element sheets being easily damaged, and achieve the effects of improving reliability and service life, high testing accuracy, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

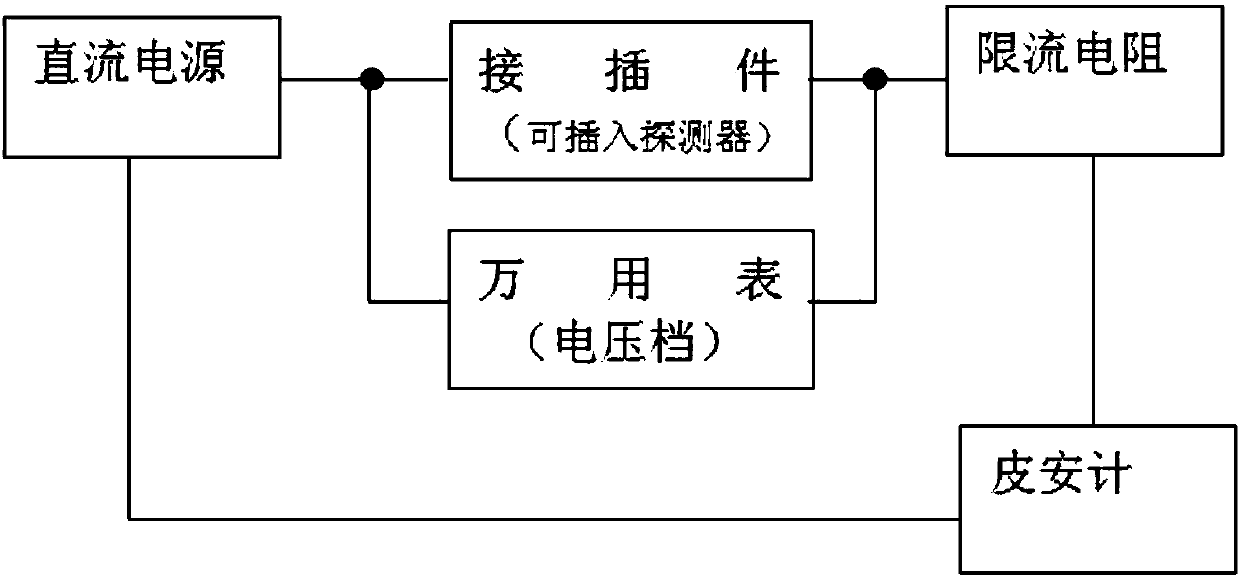

[0026] figure 2 It is a principle block diagram of the peak pressure non-destructive test of the present invention. like figure 2 As shown, this method mainly uses the principle that the thermistor-type infrared detector is powered on to generate thermal power consumption and the resistance value is reduced for testing. The DC power supply provides a stable DC voltage; the connector is a special plug-in special tooling adapted to the pins of the infrared detector, which is convenient for replacing the detector; in order to avoid over-current damage to the infrared detector, a current-limiting resistor is added to the circuit; a digital multimeter is used And set it as a voltage block to realize the real-time measurement of the working voltage at both ends of the detector; because the current value in the loop is very low, a picoammeter is used for real-time measurement of the working current in order to improve the test accuracy.

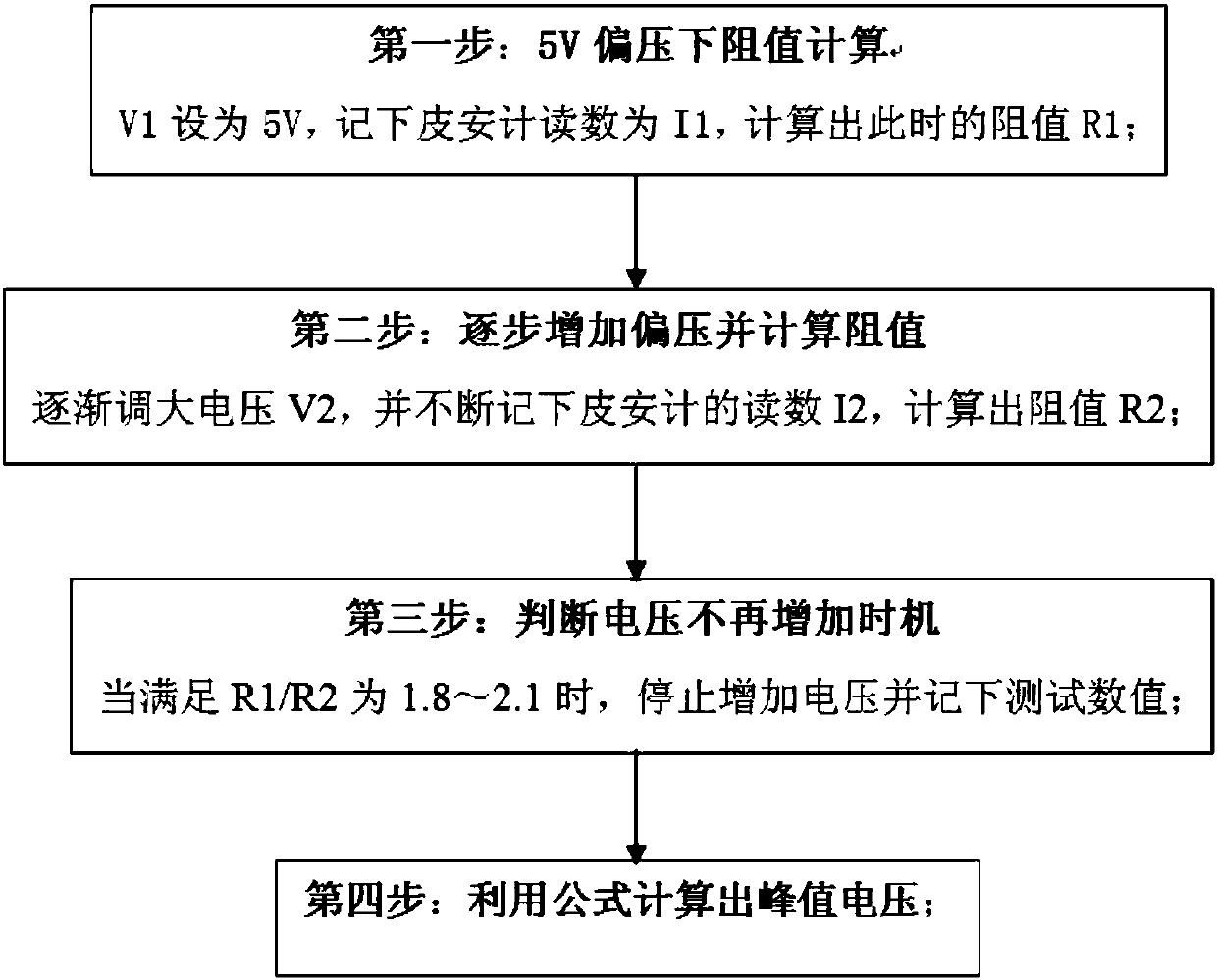

[0027] image 3 It is a flow chart of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com