Variable-temperature tension-torsion combined-load in-situ testing device and method for mechanical properties of materials

A composite load and material mechanics technology, applied in measuring devices, using stable torsion to test material strength, analyzing materials, etc., can solve the problems of difficult mechanical properties, difficult thermal field coupling, and small loading force of tensile torsion devices Achieve the effect of large loading force, high test accuracy and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

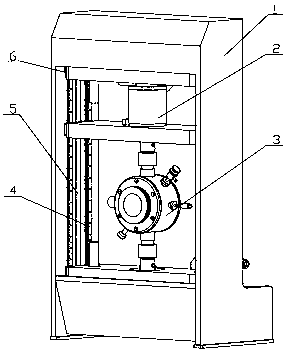

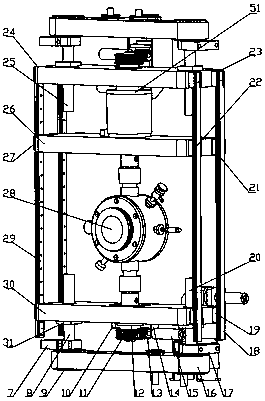

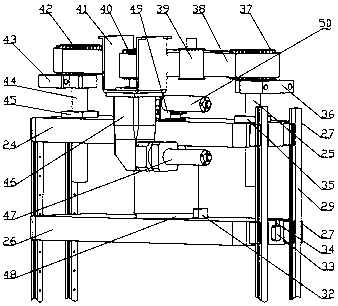

[0033] see Figure 1 to Figure 6 As shown, the in-situ test device for the mechanical properties of materials with variable temperature tension and torsion composite loads of the present invention adopts a vertical structural arrangement as a whole, including a tension unit, a torsion unit, a force and displacement detection unit, a high and low temperature loading system, and a sealed chamber 3 . The stretching unit and the torsion unit are symmetrically arranged on both sides of the sealed chamber 3 to realize bidirectional stretching-torsion. The stretching unit adopts a DC motor II47, and after being decelerated and increased by the reducer 46, it passes through the synchronous belts I, II16, 38 Drive the lead screws Ⅰ, Ⅱ, Ⅲ, Ⅳ8, 20, 25, 44 on the same side to realize synchronous rotation movement, so as to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com