Robot for detecting corrosion of base plate of on-service large-sized crude oil storage tank

A technology for crude oil storage tanks and detectors, applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., which can solve problems such as long working hours, loss of life and property of the country and people, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

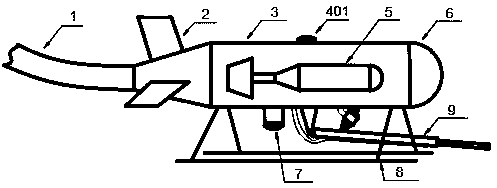

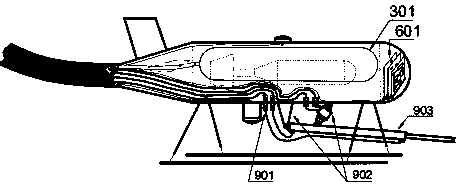

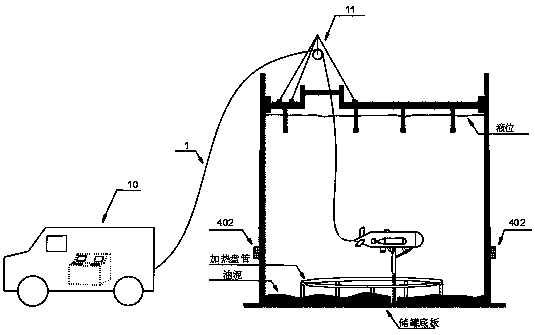

[0014] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the storage tank in-service inspection robot includes: umbilical cord (1), tail balance rudder (2), mid-section buoyancy adjustment cabin (3), weight adjustment system (301), navigation positioning signal transmitter (401), navigation Positioning signal receiving device (402), hydraulic thruster (5), front control cabin (6), electronic equipment (601), three-dimensional imaging sonar (7), base bracket (8), ultrasonic testing device (9), hydraulic pipe Joint (901), hinged mechanism (902), detection rod (903), console and display system (10), umbilical cable winch (11).

[0015] One end of the umbilical cable (1) composed of cables, data lines and hydraulic pipelines is connected to the operating console and display system (10) on the control vehicle outside the tank, and the other end passes through the winch ( 11) Lower it into the tank and connect it with the balance rudder (2) at the tail end of the robot i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com