Welding spot defect detection system based on computer vision

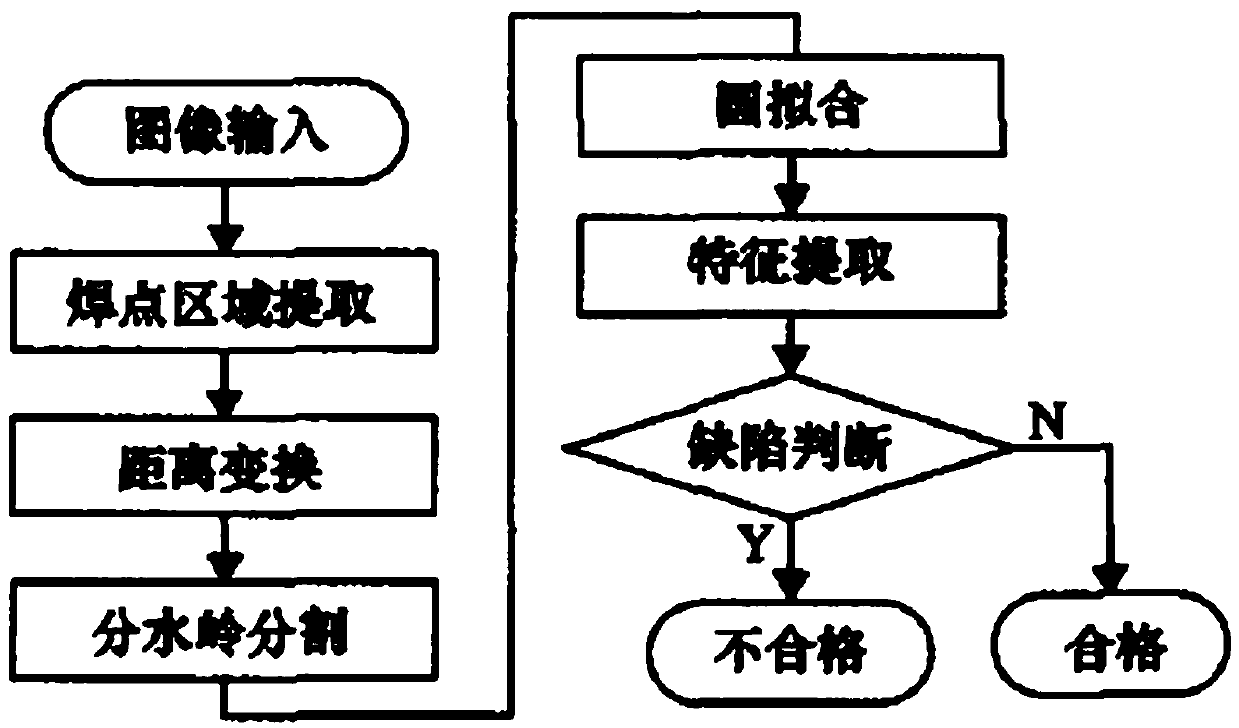

A technology of computer vision and defect detection, applied in computing, image data processing, instruments, etc., can solve the problems of extracting too many features and increasing computational complexity, and achieve the effect of improving detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The solder joint defect detection system based on computer vision is mainly composed of video acquisition equipment, control unit, PC and PC detection software. The video acquisition equipment is composed of industrial digital cameras, optical lenses and light sources. The industrial digital camera and lens are used for image acquisition of the measured object, and are connected to the host computer through the 1394 interface, and the collected image data is transmitted to the host computer for processing. In order to meet the detection accuracy of 0.1 mm, this system uses a 5 million-pixel industrial surface-scanning CCD, so that the size of a single pixel is 0.04 mm. The light source is used to illuminate and highlight the characteristics of the object. The system uses a coaxial white light source of LED particles, and adopts a front lighting method to make the background brightness uniform, that is, the pixel gray value remains consistent. The upper computer is the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com