Carbide slag-based flue gas desulfurization method

A calcium carbide slag and flue gas technology, which is applied in the field of flue gas desulfurization, can solve the problems of large solid particles, low adsorption capacity, and increased usage of desulfurizers, and achieve the effects of reduced desulfurization costs, high-efficiency desulfurization, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Modulation of desulfurizing agent composition of the present invention:

[0057] Mix the components evenly according to the following formula to obtain the desulfurizer composition.

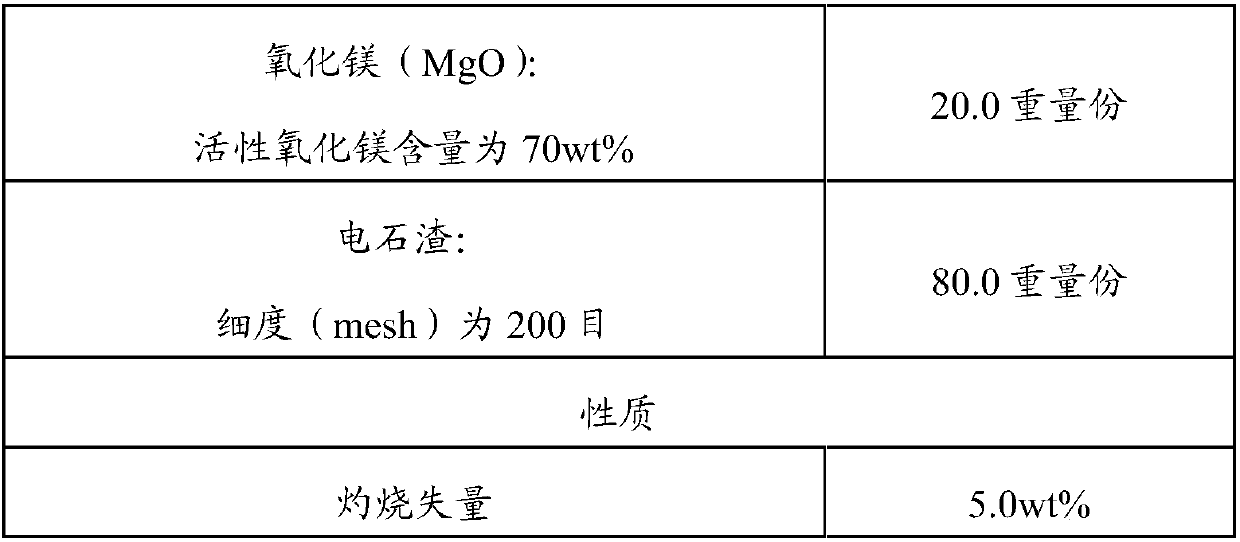

[0058] Table 1. Formula of desulfurizer composition

[0059]

[0060] (2) Flue gas desulfurization process:

[0061] 1. Pulping:

[0062] The prepared desulfurizing agent composition is added with water to make pulp, matured to form desulfurizing agent slurry, and kept in the slurry tank for later use.

[0063] 2. Flue gas desulfurization:

[0064] The sulfur dioxide in the flue gas reacts with the desulfurizer slurry in the desulfurization tower to remove the sulfur dioxide in the flue gas. The parameters of the flue gas entering the desulfurization tower are shown in Table 2.

[0065] Table 2. Inlet parameters of flue gas desulfurization

[0066] serial number

parameter

unit

value

1

Inlet flue gas volume (working condition)

m 3 / h

108...

Embodiment 2~4

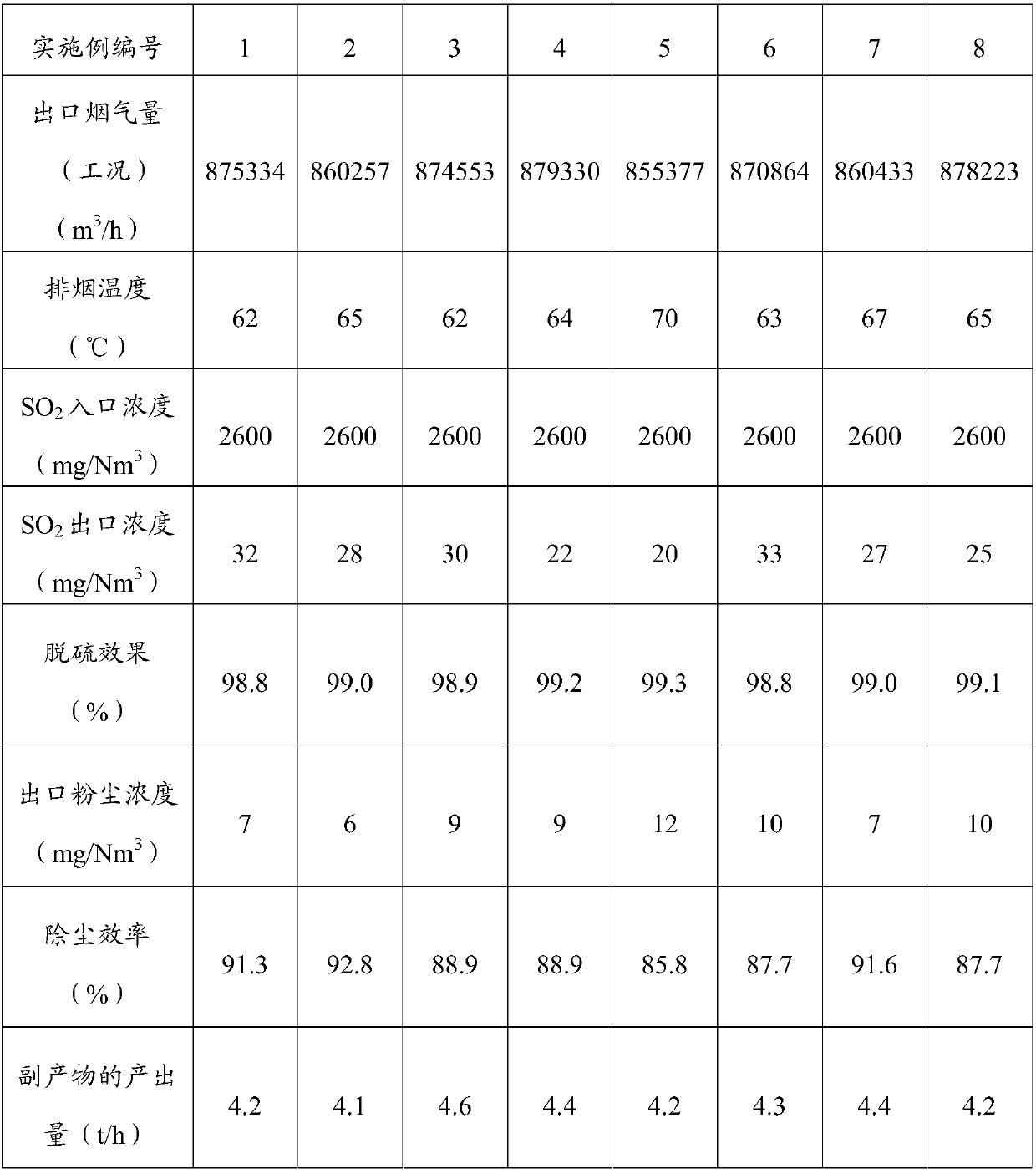

[0078] The flue gas desulfurization and magnesium sulfate production were carried out under the same conditions as in Example 1 except that the formulations in each desulfurizer composition were adjusted according to Table 3. The desulfurization effect is shown in Table 4.

[0079] Table 3. Formulas of each desulfurizer composition

[0080] Element

Embodiment 5

[0082] Other conditions were the same as in Example 1 except that the desulfurization slurry was discharged when the pH value reached 5.8. The desulfurization effect is shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com