Hot cleaning furnace with double purifying treatment function

A purification treatment and heat cleaning furnace technology, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of air pollution, ecological environment damage, and insufficient purification treatment, and achieve the effect of protecting the environment and the atmosphere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

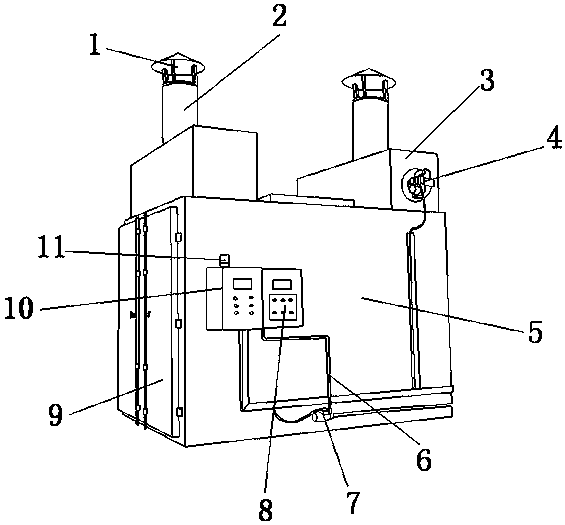

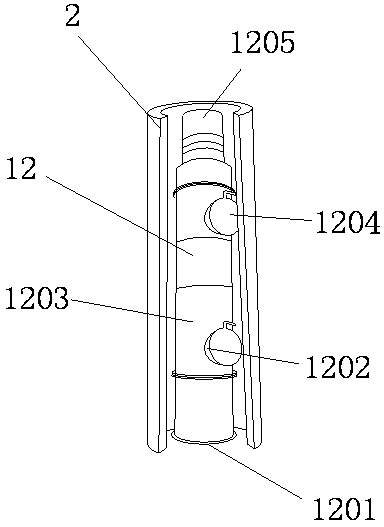

[0019] see figure 1 , figure 2 , the present invention provides a technical solution of a heat-cleaning furnace with double purification treatment: its structure includes a waterproof cap 1, an exhaust chimney 2, an exhaust gas combustion chamber 3, a combustion chamber burner 4, a decomposition chamber 5, a water pipe 6, and a water pump motor 7 , fire control box 8, explosion-proof safety door 9, manipulator 10, alarm 11, carbon dioxide absorber 12, carbon dioxide absorber 12 is embedded in the exhaust chimney 2, and the exhaust chimney 2 is connected with the waterproof cap 1 through the support rod connected, the combustion chamber burner 4 is embedded and installed in the exhaust gas combustion chamber 3, the exhaust gas combustion chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com