Multi-pin plug-in component removal method for aircraft circuit board maintenance

A component and circuit board technology, applied in the field of multi-pin insertion component removal, can solve problems such as the removal of multi-pin insertion components that have not been applied, improve work efficiency and flexibility, ensure rationality and quality and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

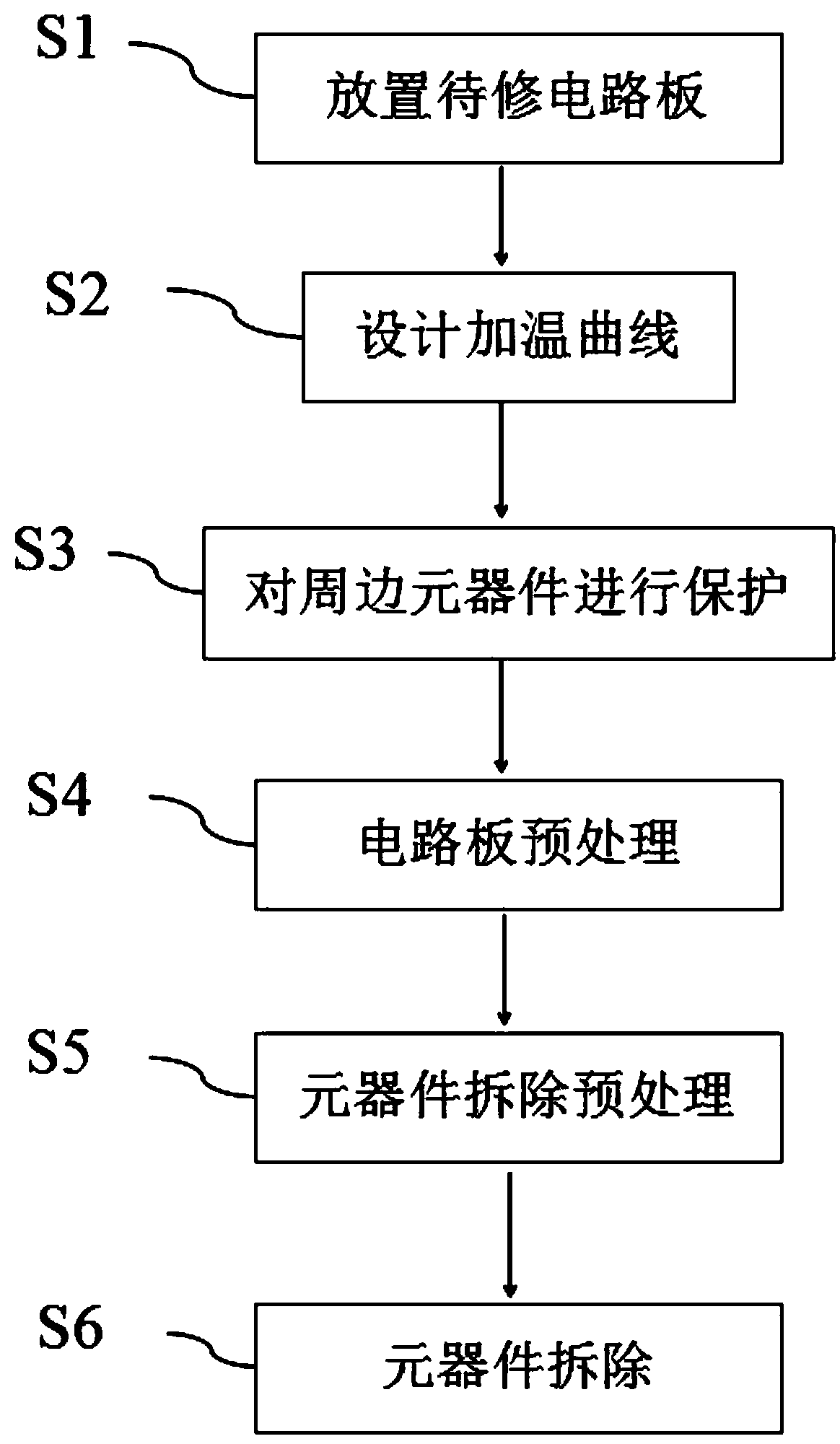

[0028] Such as image 3 The operation flow chart shown, a method for removing multi-pin plug-in components for repairing aircraft circuit boards, includes steps:

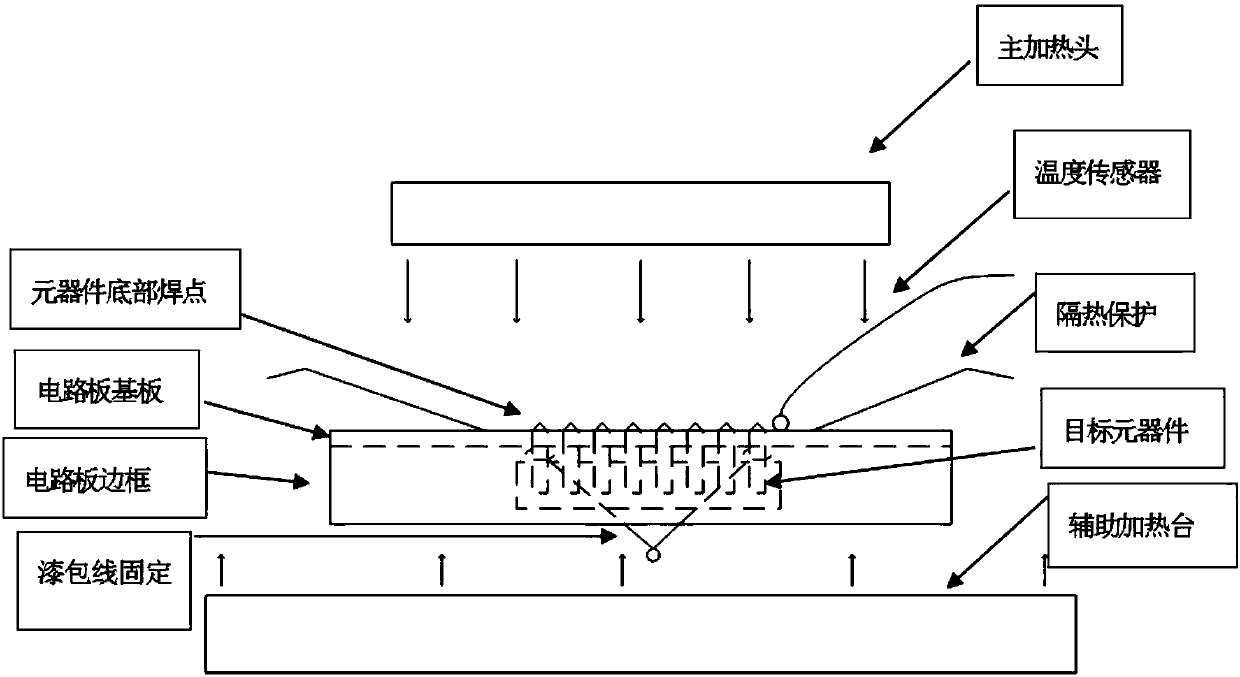

[0029] S1) place the circuit board to be repaired, such as figure 1 The schematic diagram of the operation shown:

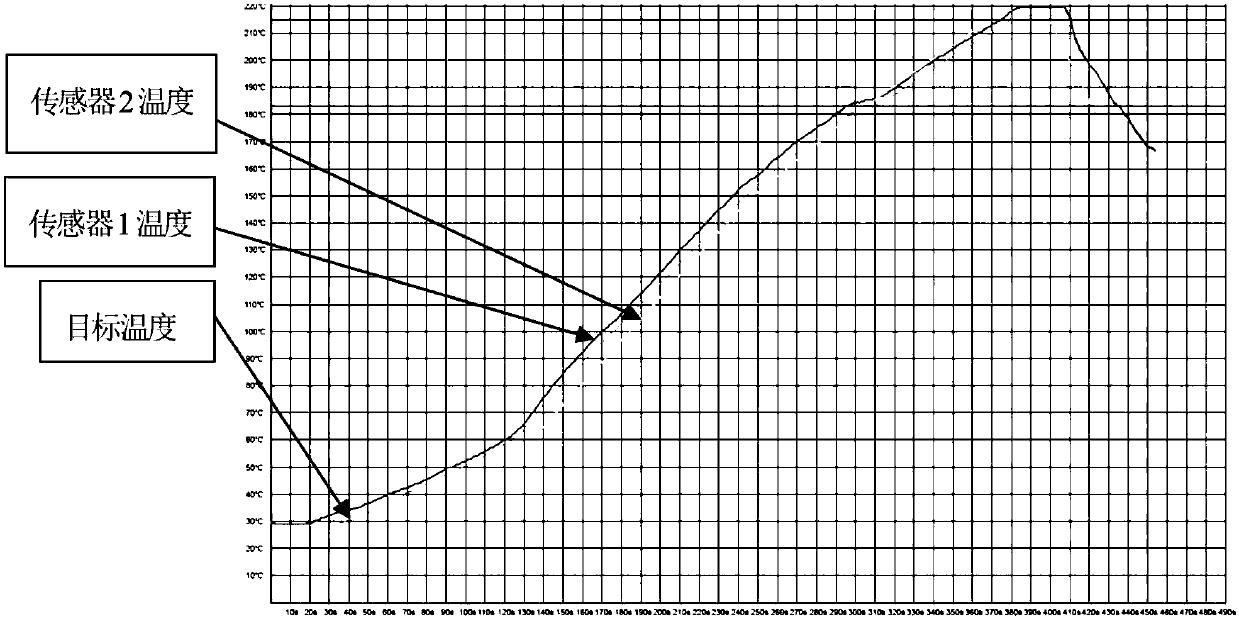

[0030] The components of the rework station include a main heating head, a temperature sensor, and an auxiliary heating table. The main heating head adopts a mixed heating method of infrared and hot air, and the heating temperature is controllable. The temperature sensor can be connected to the computer through the main board of the rework station to view the temperature-time curve in real time. By designing the temperature curve, the negative feedback network composed of the main heating head and the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com