Catalyst component for olefin polymerization, and preparation method thereof, and catalyst for olefin polymerization, and applications thereof

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization, and can solve the problems of non-preparation, low isotacticity of polypropylene, poor stereospecificity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the present invention, the magnesium source can be various magnesium-containing compounds that can be used as catalysts for olefin polymerization, for example, the magnesium source can be magnesium halide, magnesium alcoholate or halogenated alcoholate and magnesium halide adduct The magnesium halide can be, for example, magnesium chloride and / or magnesium bromide; the magnesium alcoholate can be, for example, diethoxymagnesium; Magnesium; the type of the magnesium halide adduct carrier is known to those skilled in the art, for example, the disclosed magnesium halide adduct carrier such as CN1091748A, CN101050245A, CN101486722A, 201110142357.X, 201110142156.X and 201110142024.7, and these patents The relevant content of the disclosure is fully incorporated into this application as a reference. The specific preparation method of the magnesium halide adduct carrier may include the following steps: mixing the components forming the magnesium halide adduct, heating and r...

Embodiment approach

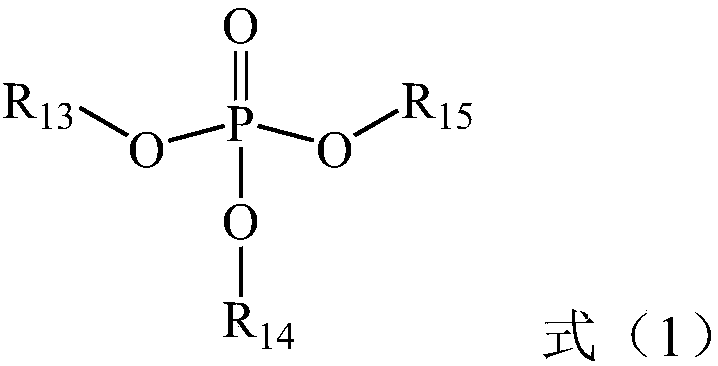

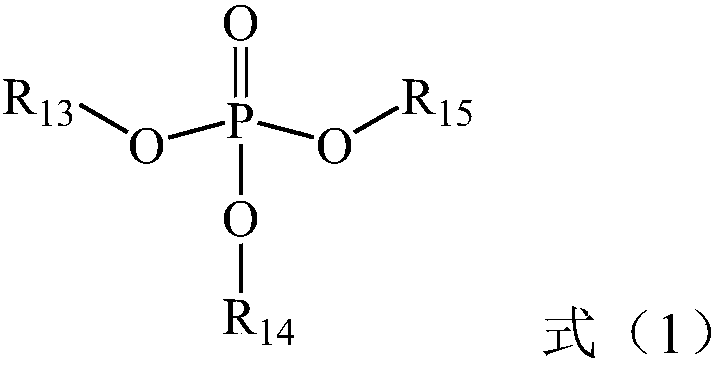

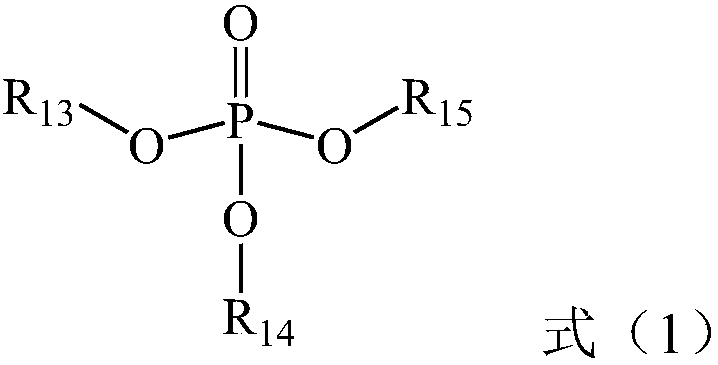

[0046] According to a preferred embodiment of the present invention, the amount of the magnesium source, the titanium source and the internal electron donor is such that, based on the total weight of the catalyst component, the phosphorus content in the catalyst component is 0.002- 0.05% by weight, preferably 0.005-0.04% by weight.

[0047] Specifically, the reaction between the magnesium source and the titanium source can be carried out in the same manner as in the prior art, for example, the titanium source can be cooled below 0°C (preferably -5 to -25°C), and then the magnesium source is added, Stir and mix at this temperature for 10-60 minutes, then raise the temperature to the reaction temperature (ie about 60-130° C.), and maintain at the reaction temperature for 0.5-10 hours. In the preparation method of the catalyst component for olefin polymerization, the internal electron donor is added within one or more periods of time before, during and after the reaction of the m...

Embodiment 1

[0070] This example is used to illustrate the catalyst component for olefin polymerization and its preparation method, catalyst for olefin polymerization and application of the present invention.

[0071] (1) Preparation of catalyst components

[0072] In a 300ml glass reaction bottle, add 90ml (820mmol) of titanium tetrachloride and cool to -20°C, add 37mmol of magnesium halide carrier (prepared according to the method disclosed in CN1330086A Example 1) in terms of magnesium element, wherein, Then the temperature was raised to 110°C, and 0.3mmol of tributyl phosphate and 7.3mmol of 2-isopropyl-2-isopentyl-1,3-dimethoxypropane were added during the temperature rise, and maintained at 110°C After 30 minutes, the liquid was filtered off, washed twice with titanium tetrachloride and five times with hexane, and dried in vacuum to obtain the catalyst component Cat-1 for olefin polymerization.

[0073] As measured by X-ray fluorescence spectroscopic analysis, the phosphorus content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com