Low-elasticity and anti-slip rubber and preparation method thereof

A non-slip and rubber technology, applied in the field of low-elastic anti-slip rubber and its preparation, can solve the problems of inability to achieve wear resistance and low elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

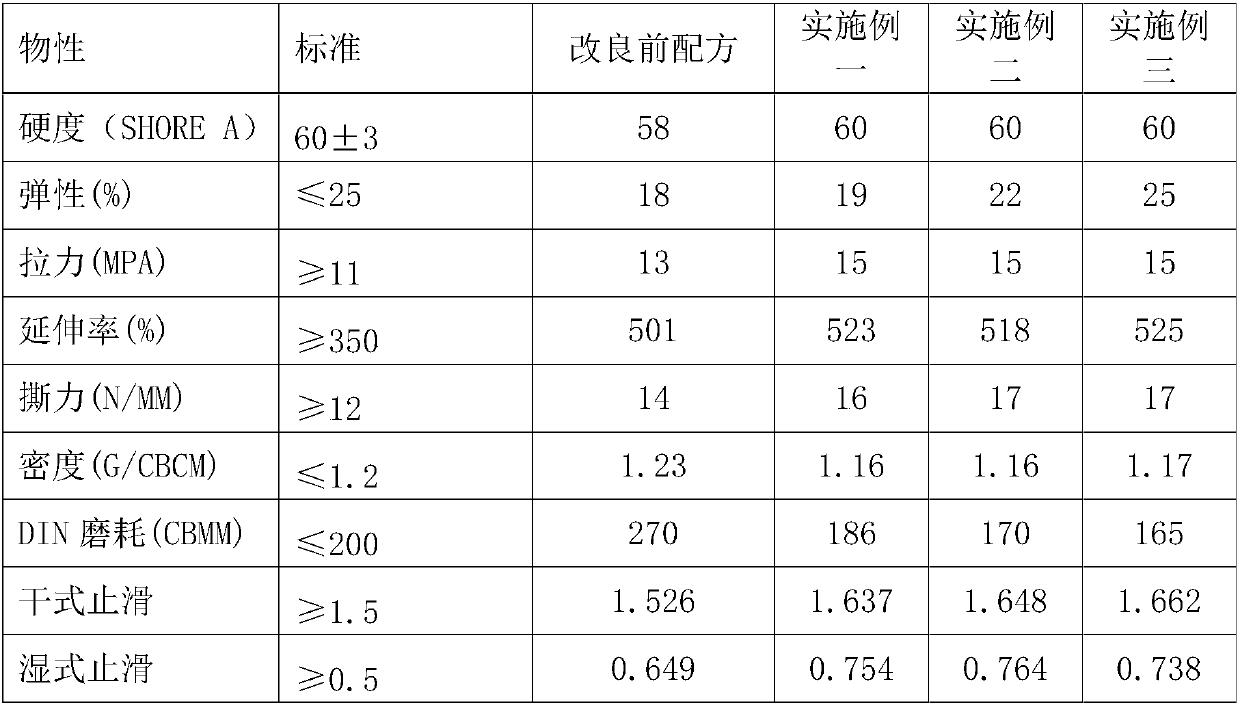

Examples

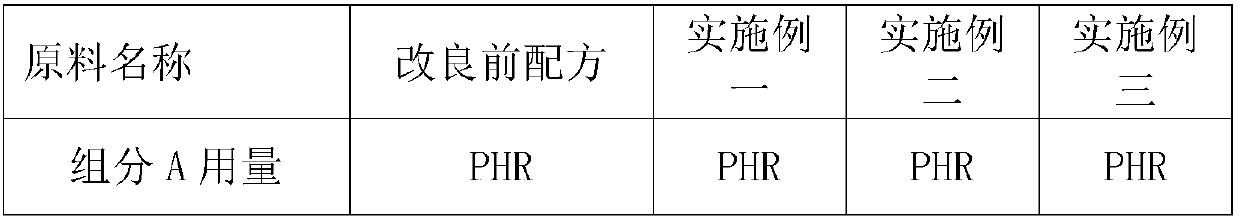

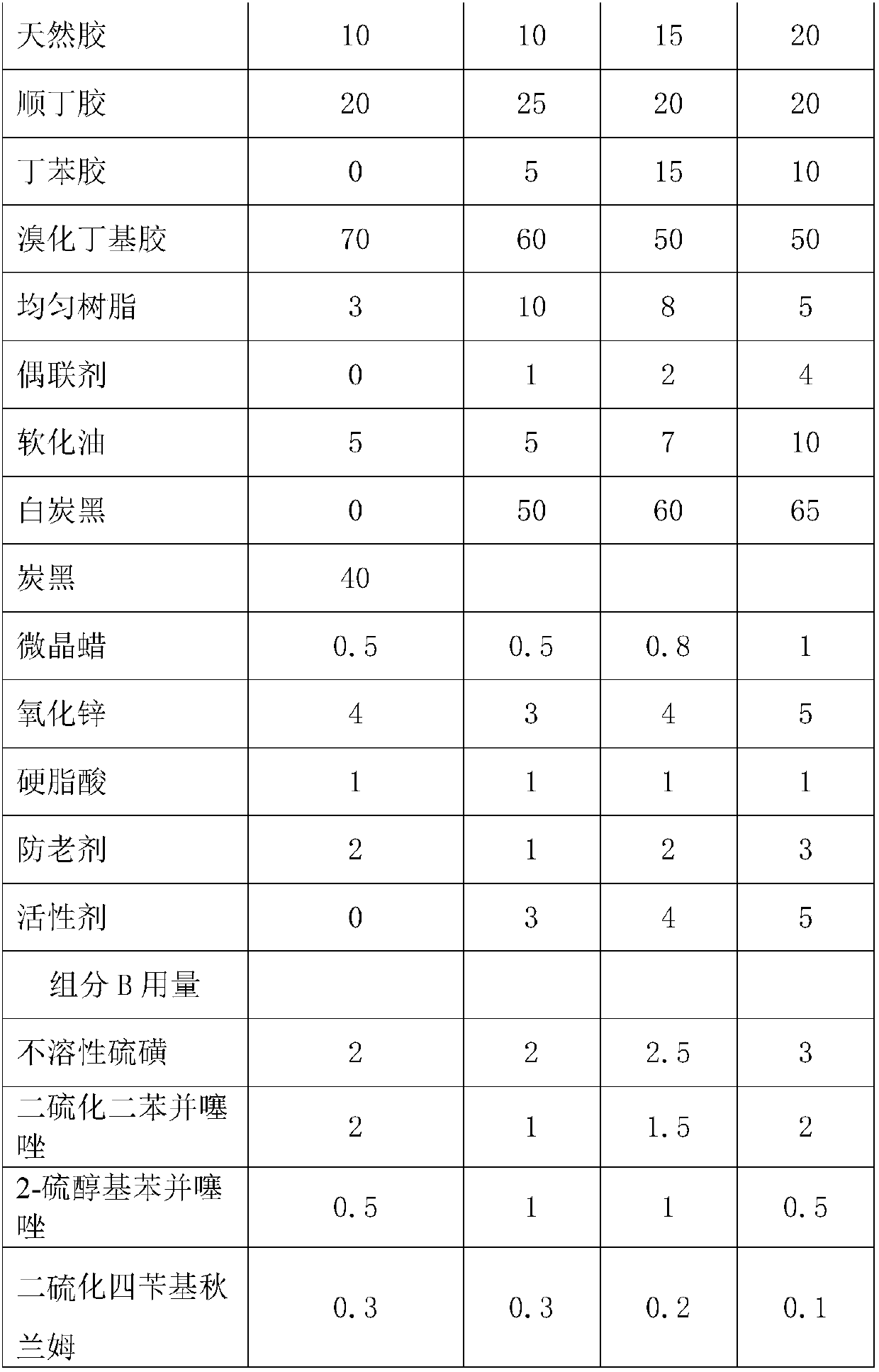

Embodiment 1-3

[0028] The preparation steps of the low-elastic anti-slip rubber of the present embodiment 1-3 are as follows:

[0029] 1. 10,000-horsepower machine operation (raw material component A automatic mixing program)

[0030] 1.1 Turn on the vacuum cleaner before putting in the rubber and resin for mixing 40"

[0031] 1.2 Pour in 2 / 3 of the white smoke and oil, and then press the hammer into the mixing 60"

[0032] 1.3 Put 1 / 3 of the white smoke and all the medicines into it, press the hammer into the mixing chamber for 50" and then clean it

[0033] 1.4 The material can be unloaded after the mixing is OK, and the unloading temperature is controlled below 130°C.

[0034] 2. Mill operation to produce tablets:

[0035] 2.1 Unload the rubber material unloaded from the 10,000-horsepower machine once, and turn it over on the turning machine

[0036] The material is operated for 2 minutes, and then the coiled material is overcooled, and the temperature of the rubber material is contro...

Embodiment 1

[0052] The coupling agent of embodiment 1-3 is respectively 3-thiocyanopropyltriethoxysilane (embodiment 1), 3-mercaptopropyltriethoxysilane (embodiment 2), vinyl tri(2 -methoxyethoxyl) silane (embodiment 3); the antioxidant of embodiment 1-3 is respectively 2,6-di-tert-butyl p-cresol (embodiment 1), antioxidant CPL (embodiment 2 ), anti-aging agent 1076 (embodiment 3); the activator of embodiment 1-3 is polyethylene glycol (embodiment 1), activator KETTLITZ AKTIOL (embodiment 2), activator R1987 (embodiment 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com