Battery pack assembly method

A technology of battery packs and battery packs in series, applied in the direction of secondary battery repair/maintenance, etc., can solve problems such as short cycle life, low rate of unmatched groups, and failure to grasp the essence of key points, etc., to achieve improved performance, high consistency, Life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

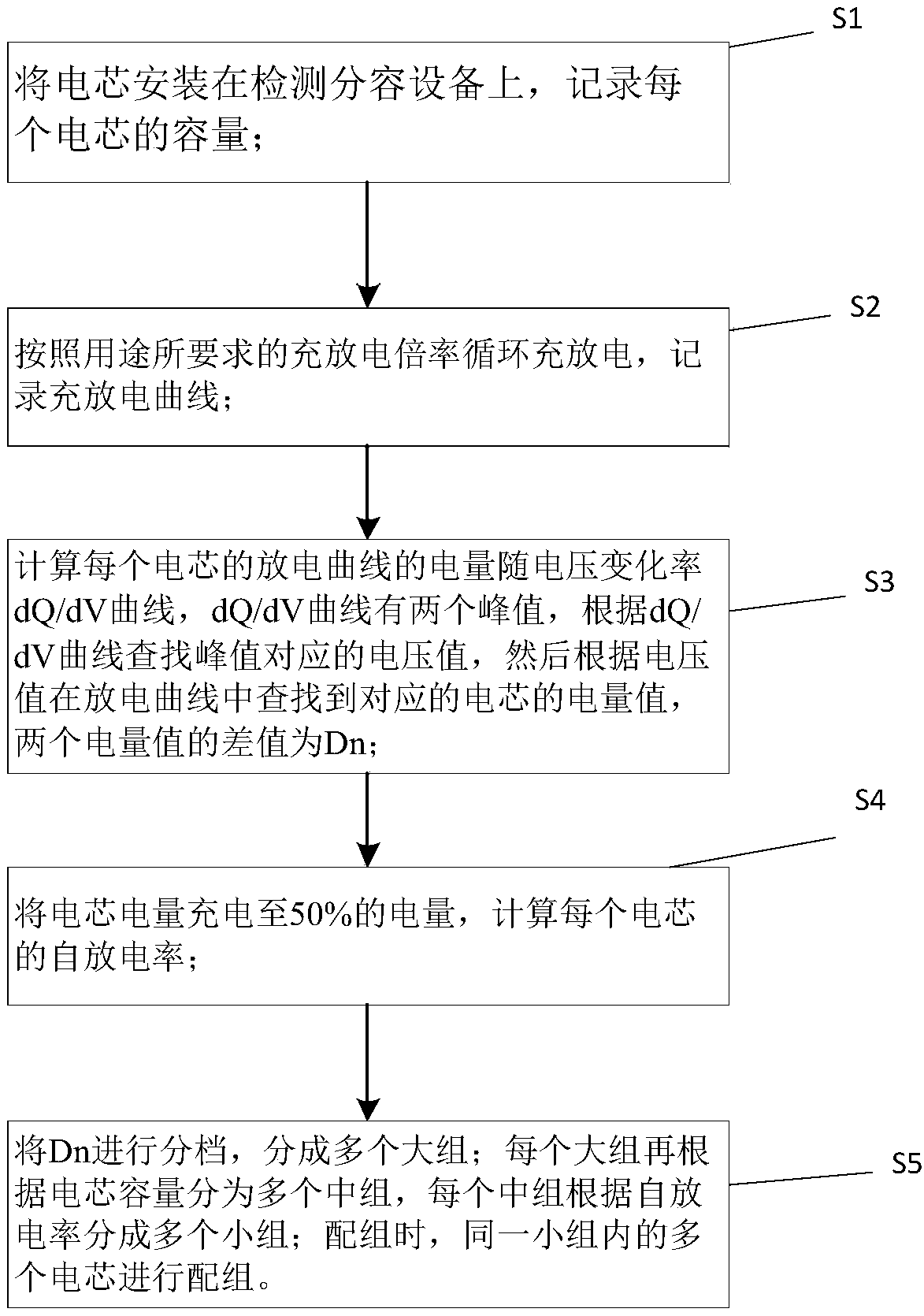

[0019] As shown in the figure, a battery pack matching method includes the following steps:

[0020] S1. Install the battery cells on the capacity detection equipment, and record the capacity of each battery cell; the capacity of a single battery cell is the average value of multiple measured capacities as the capacity value of the battery cell and recorded.

[0021] S2. Cycle charge and discharge according to the charge and discharge rate required by the application, and record the charge and discharge curve; here, according to the different uses of the group of batteries, the charge and discharge rate of the battery is also required to be different, and the cycle charge and discharge are carried out at the charge and discharge rate when it is working. Detect its charge and discharge curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com