Chest filler and manufacturing method thereof

A filler and breast technology, applied in the direction of fake breasts, additive processing, etc., can solve the problems of lesion fragments, free, poor breast augmentation effect, etc., achieve the effect of reducing displacement, resisting capsular contracture, and achieving long-term stable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

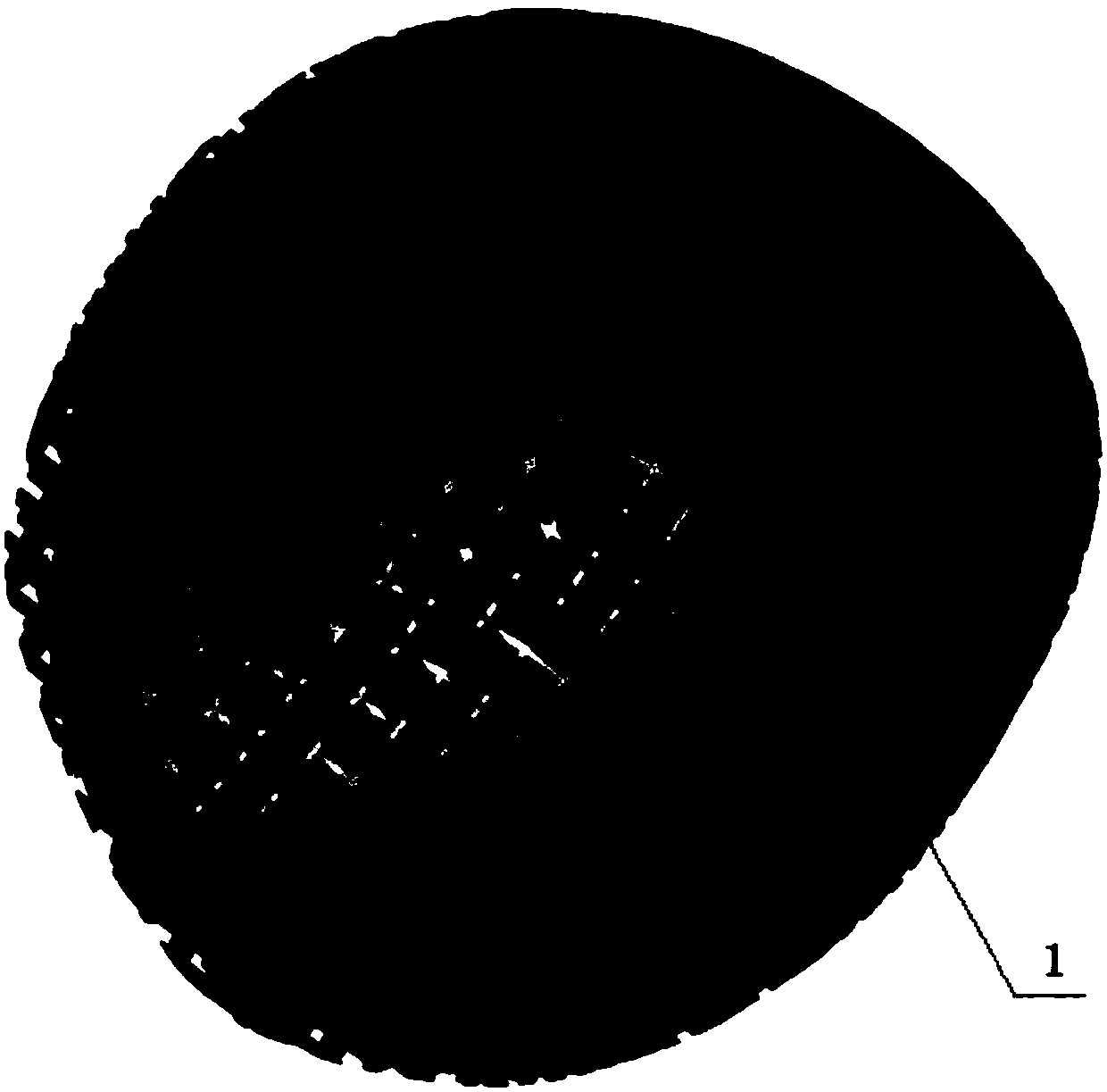

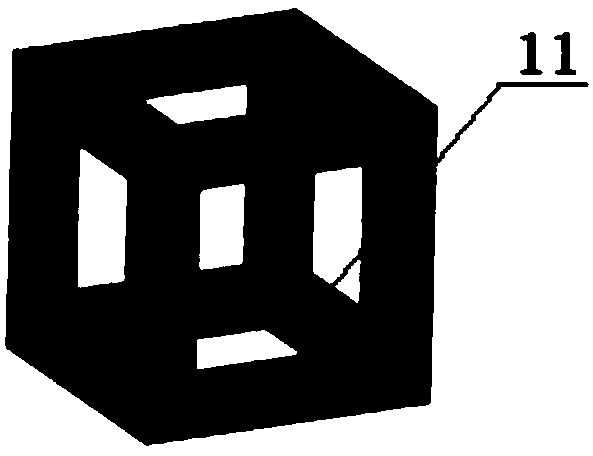

[0039] Such as figure 1 and figure 2 As shown, the breast filler 1 is a three-dimensional network chest structure composed of many repeated regular hexahedral porous units 11 connected to each other. The porous unit 11 is a regular hexahedron structure that is connected to each other by a plurality of linear edges of the same length. The porous units 11 are connected to each other, so that the host's own tissue can grow into the openings of the interconnected porous units 11. The chest filler 1 The overall porosity is 30%, the thickness of the breast filler 1 is 50 mm, the equivalent spherical diameter of the porous unit 11 is 150 μm, and the equivalent spherical diameter of the connecting part between any two porous units 11 is 500 μm. The porous units 11 are evenly distributed on the chest filler 1 .

[0040] Specifically, the above-mentioned chest filler 1 is made by heat-curing silicone rubber 3D printing method, and the specific steps are as follows: obtain the chest i...

Embodiment 2

[0042] Such as Figure 6 As shown, the breast filler 1 is a three-dimensional network chest structure composed of many repeated helical dodecahedral porous units 11 connected to each other. The porous unit 11 is a dodecahedron structure formed by interconnecting multiple helical ribs with the same length. The spiral rib is a three-dimensional helical structure, and the porous units 11 are interpenetrated and connected with each other, so that the host's own tissue can grow into the openings of the interpenetrated and connected porous units 11. The overall porosity of the chest filler 1 is 30%, and the chest filler The thickness of object 1 is 50 mm, the equivalent spherical diameter of the porous unit is 150 μm, and the equivalent spherical diameter of the connecting part between any two porous units is 500 μm.

[0043] What needs to be explained here is that the porous unit 11 using hexahedron and dodecahedron in the above-mentioned embodiment is only a preferred solution, t...

Embodiment 3

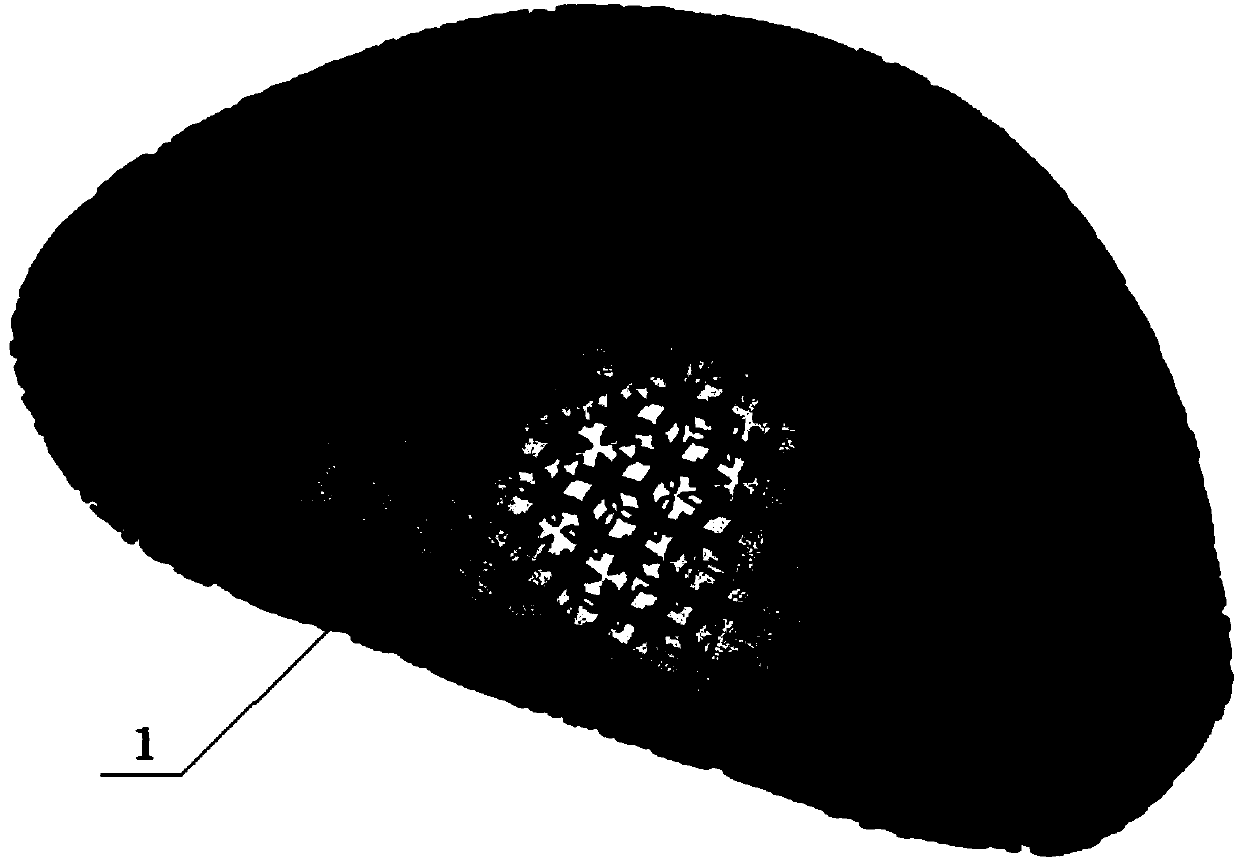

[0045] The difference between embodiment 3 and embodiment 1 is that, as Figure 3 to Figure 5 As shown, the chest filling 1 includes a shell and a solid structure 2. The shell is a three-dimensional network structure composed of many repeated porous units 11 connected to each other. The dodecahedron structure, the solid structure 2 is a 100% solid chest-shaped structure, which can be made of the same material as the shell, the shell covers the upper surface of the solid structure 2, and the entire chest filling 1 is integrally formed. In addition, the above solution is only a preferred solution, and the shell can also be covered on the entire outer peripheral surface of the solid structure 2 or partially cover the outer peripheral surface of the solid structure 2 . The porous units 11 are interconnected so that the host's own tissue can grow into the openings of the interconnected porous units 11 of the chest filler 1. The overall porosity of the chest filler 1 is 20%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com