Ultra-deep desulfurization catalyst and preparation method thereof

A deep desulfurization and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low stability of metal chelates, low catalytic activity, uneven dispersion of metal components, etc. , to achieve the effects of weakening steric hindrance, high dispersion and appropriate stacking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

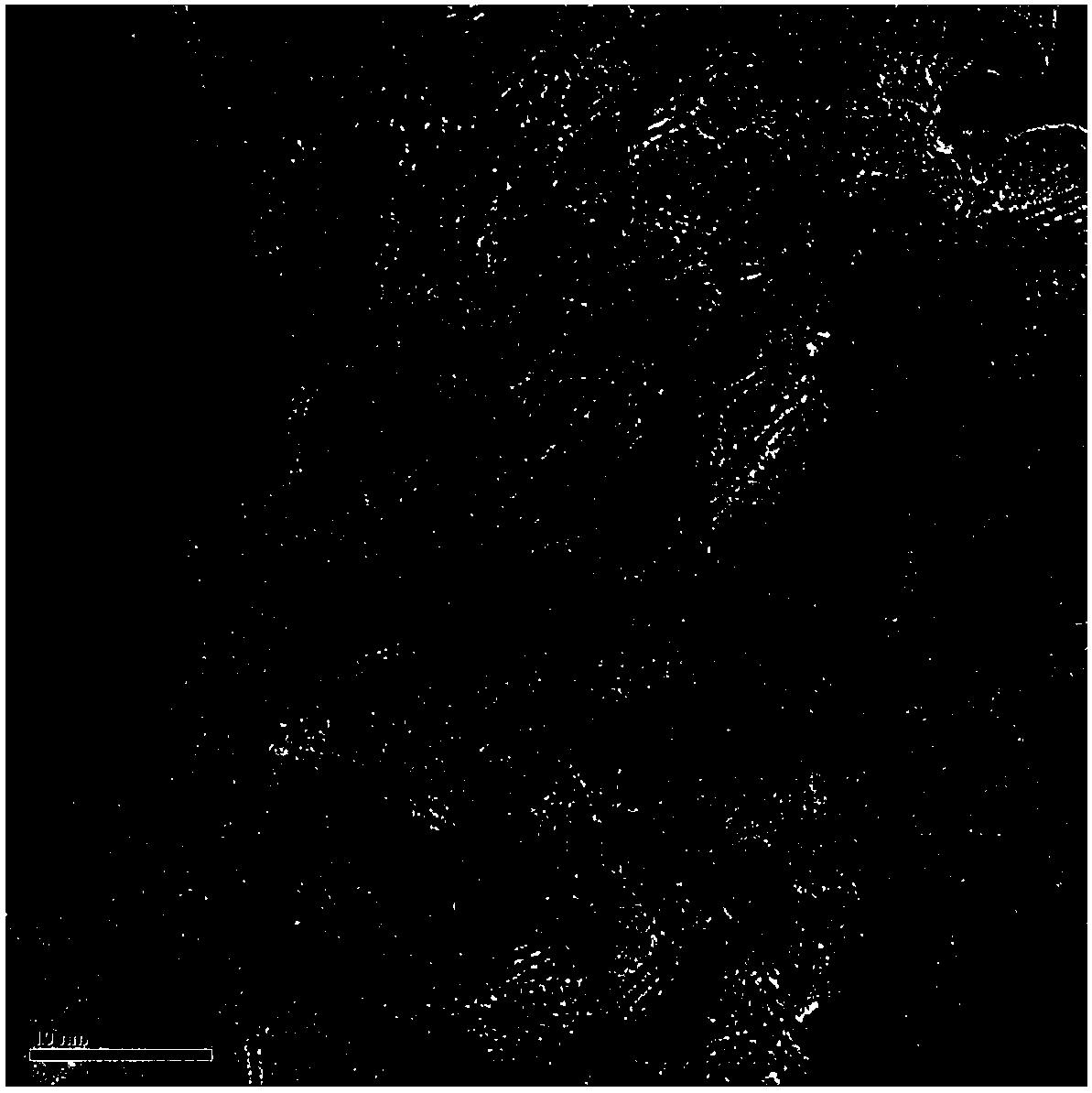

Image

Examples

Embodiment 1

[0052] This embodiment provides a method for preparing an ultra-deep desulfurization catalyst, the method comprising the following steps:

[0053] 1.04g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 50ml of deionized water, and then the pH was adjusted to 3.0 with a concentration of 2.4mol / L HCl solution; at 50°C, 20ml concentration of 0.074mol / L (C 16 h 33 N(CH 3 ) 2 C 6 h 12 N(CH 3 ) 2 C 16 h 33 )Br 2 solution, adjust the pH to 3.0 with a HCl solution with a concentration of 2.4mol / L, and stir at a constant temperature of 50°C for 2h; centrifuge the solution and dry it at 100°C for 6h to obtain a Mo-based precursor connected to a double-ended quaternary ammonium salt;

[0054] Will contain 96.4wt.% Al 2 o 3 and 3.6wt.% SiO 2 SiO 2 -Al 2 o 3 The carrier is compressed into tablets under a pressure of 10 MPa, and passed through a 20-40 mesh sieve to obtain the carrier SA;

[0055] Take 1.791g of the above-mentioned Mo-based precursor and disperse it in 70ml o...

Embodiment 2

[0060] This embodiment provides a method for preparing an ultra-deep desulfurization catalyst, the method comprising the following steps:

[0061] 1.04g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 50ml of deionized water, and then the pH was adjusted to 3.0 with a concentration of 2.4mol / L HCl solution; at 80°C, 20ml concentration of 0.074mol / L (C 8 h 17 N(CH 3 ) 2 C 6 h 12 N(CH 3 ) 2 C 8 h 17 )Br 2 solution, adjust the pH to 3.0 with a HCl solution with a concentration of 2.4mol / L, and stir at a constant temperature of 80°C for 3h; centrifuge the solution and dry it at 100°C for 6h to obtain a Mo-based precursor connected to a double-ended quaternary ammonium salt;

[0062] Will contain 96.4wt.% Al 2 o 3 and 3.6wt.% SiO 2 SiO 2 -Al 2 o 3 The carrier is compressed into tablets under a pressure of 10 MPa, and passed through a 20-40 mesh sieve to obtain the carrier SA;

[0063] Take 1.791g of the above-mentioned Mo-based precursor and disperse it in 70ml of ...

Embodiment 3

[0068] This embodiment provides a method for preparing an ultra-deep desulfurization catalyst, the method comprising the following steps:

[0069] 1.04g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 50ml of deionized water, and then the pH was adjusted to 3.0 with a concentration of 2.4mol / L HCl solution; at 30°C, 20ml concentration of 0.049mol / L (C 16 h 33 N(CH 3 ) 2 C 6 h 12 N(CH 3 ) 2 C 6 h 12 N(CH 3 ) 2 C 16 h 33 )Br 2 solution, adjust the pH to 2.0 with a HCl solution with a concentration of 2.4mol / L, and stir at a constant temperature of 30°C for 2h; centrifuge the solution and dry it at 120°C for 6h to obtain a Mo-based precursor connected to a double-ended quaternary ammonium salt;

[0070] Will contain 96.4wt.% Al 2 o 3 and 3.6wt.% SiO 2 SiO 2 -Al 2 o 3 The carrier is compressed into tablets under a pressure of 10 MPa, and passed through a 20-40 mesh sieve to obtain the carrier SA;

[0071] Take 1.791g of the above-mentioned Mo-based precursor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com