Abrasion-resistant vibration material conveying hopper applied to large-particle ore separation machine

A sorting machine and conveying bucket technology, which is used in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of wear and tear of the conveying bucket body, high price, wear and damage of the surface of the receiving conveying plate, etc., to achieve reasonable The effect of reuse, reduction of production cost, and improvement of conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

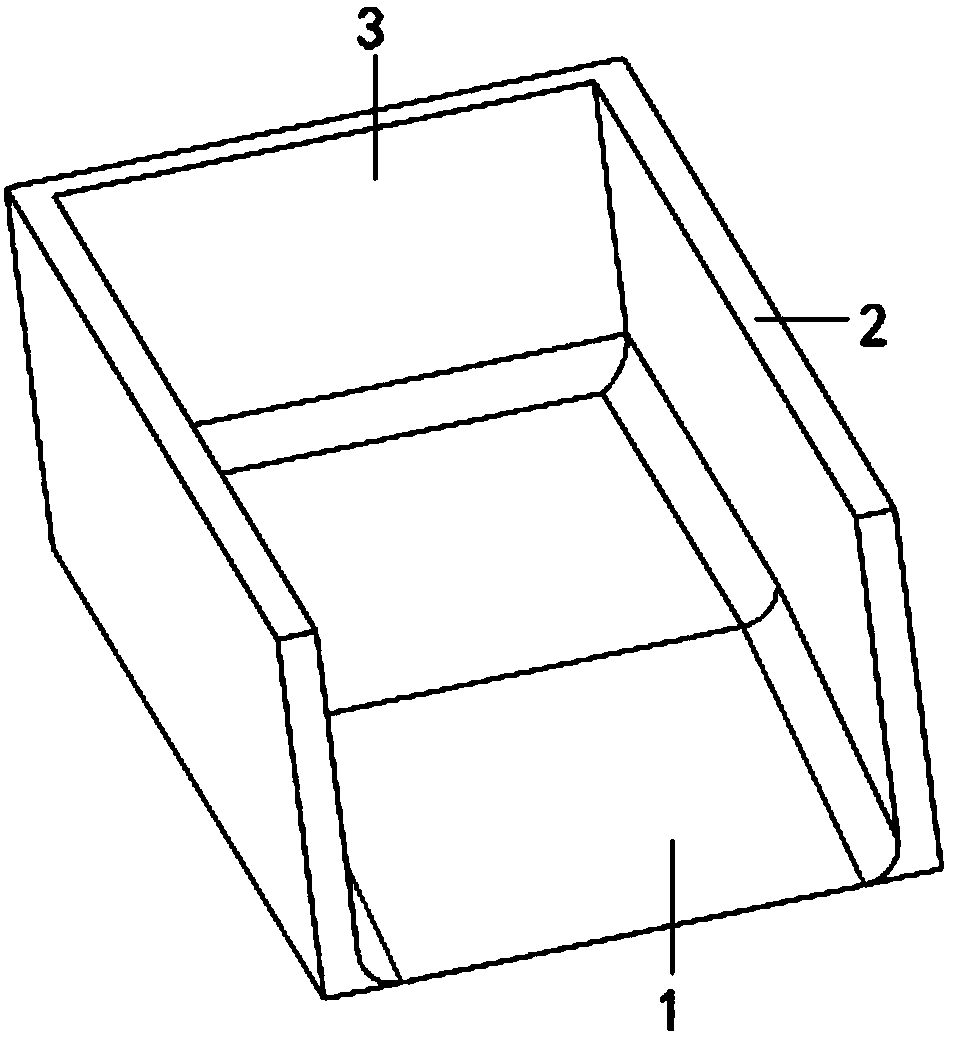

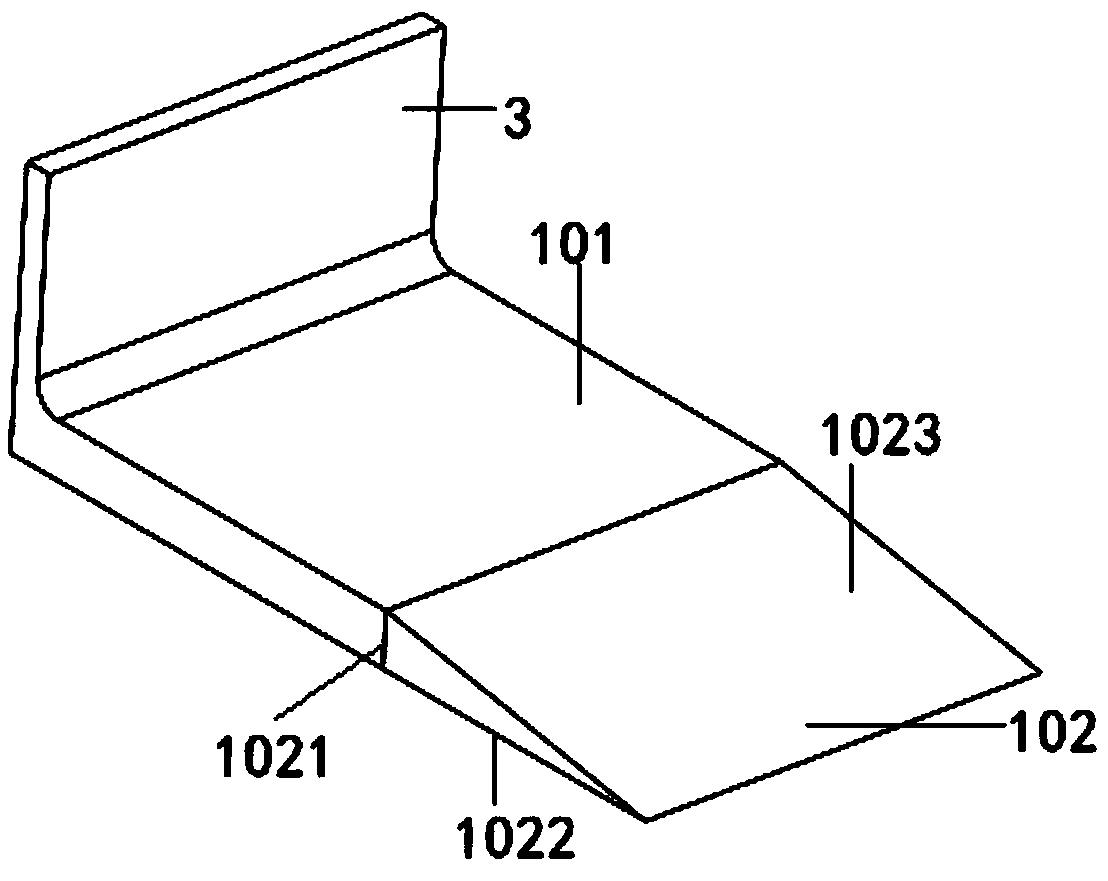

[0032] A wear-resistant vibrating material conveying bucket applied to a large-grain ore separator, such as figure 1 and figure 2 As shown, it includes a material-receiving conveying plate 1, two oppositely arranged first baffles 2 are vertically fixed on both sides of the material-receiving conveying plate 1, and a second baffle 3 is vertically connected between the two first baffles. The second baffle plate 3 is vertically connected with the material receiving conveying plate 1, and the connection between the material receiving conveying plate 1 and the first baffle plate 2 and the second baffle plate 3 is rounded, which can reduce the accumulation of ore powder at the joint, and remove convenient;

[0033] The material receiving and conveying plate 1 includes a first material receiving plate 101 and a second material receiving plate 102 fixedly connected in sequence, the first material receiving plate 101 and the second material receiving plate 102 are integrally formed, ...

Embodiment 2

[0042] The conveying bucket body of the present invention is prepared by a silicon carbide composite material, and the preparation process of the conveying bucket body is as follows:

[0043] (1) Wash the discarded rice husks with deionized water, dry and pulverize them at 60°C, add a certain amount of concentrated sulfuric acid to the crushed rice husks, add 5L of concentrated sulfuric acid to 1kg of rice husks, and dry them at 100°C Under heating and stirring for 15h, then use 0.1mol.L -1 sodium bicarbonate and deionized water to neutrality, dried at 60 ° C to obtain carbonized rice husk;

[0044] (2) Add the carbonized rice husk prepared in step 1 into the phenolic resin solution, wherein 1g of the carbonized rice husk is added with 50mL of the phenolic resin solution, and mix well to obtain a colloidal solution. After the ratio is mixed evenly, the activation process of the activated powdered molecular sieve is as follows: put the powdered molecular sieve into a muffle fu...

Embodiment 3

[0050] The conveying bucket body of the present invention is prepared by a silicon carbide composite material, and the preparation process of the conveying bucket body is as follows:

[0051] (1) Wash the discarded rice husks with deionized water, dry and pulverize them at 40-60°C, and roast the crushed rice husks in a muffle furnace at 600-700°C for 3-8 hours to obtain carbonized rice husks ;

[0052] (2) Add the carbonized rice husk prepared in step 1 into the phenolic resin solution, wherein 1g of the carbonized rice husk is added with 40mL of the phenolic resin solution, mix well to obtain a colloidal solution, and mix the colloidal solution with the activated powder molecular sieve in a mass ratio of 28:1 After mixing evenly, the activation process of the activated powdered molecular sieve is as follows: put the powdered molecular sieve into a muffle furnace, dry and react at 350°C for 9 hours, put it into a closed reaction container and cool it with liquid nitrogen, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com