Preparation method and application of low-degradation tension glass fibers

A glass fiber, tension technology, used in transportation and packaging, transportation of filamentous materials, thin material processing, etc., to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

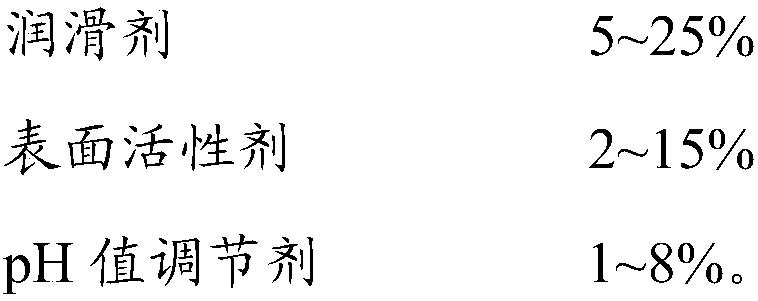

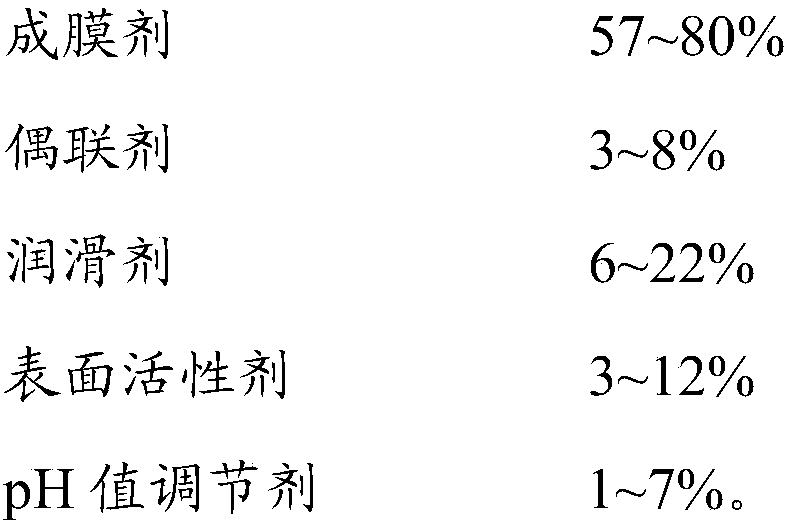

[0045] 1S preparation of wetting agent: Take glacial acetic acid with a mass of 2.8% in total and deionized water to prepare a solution with a mass ratio of 1:30, add Momentive A-187 epoxy silane coupling agent with a mass of 2.2% in total , stirring at a speed of 2000rpm for 30min; adding a mass of 55% of the total amount of DSMJS-19 and JS-206 mixed epoxy emulsion film-forming agent, adding a mass of 25% of the total amount of Jushi Group TX-507 and Pulcra Chemicals JS-808 mixed PEG lubricant, adding TX-E10 surfactant with a mass of 15% in total, and adding deionized water again to prepare a uniform and stable wetting agent, wherein the solid content of the wetting agent is 5wt%, The mass ratio of coupling agent and film-forming agent is controlled to be 1:25;

[0046] 2S coating sizing agent: place the sizing agent prepared in step 1S in the oiling box of the oiler, and apply the sizing agent by passing the glass fiber bundles through the oiling roller of the oiler to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com