Preparation method of surface wear-resistant coating for nodular cast iron

A technology of nodular cast iron and wear-resistant coating, which is applied in coating, metal material coating process, solid-state diffusion coating, etc. Solve the effect of low bonding strength, good bonding force and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

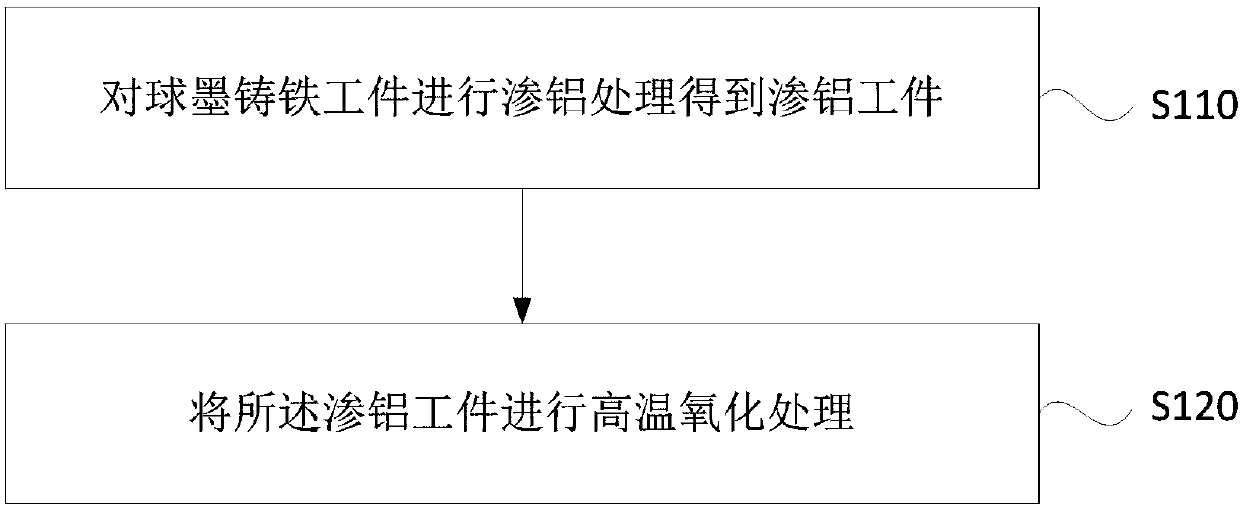

[0022] The preparation method (abbreviation method) of wear-resistant coating on the surface of ductile iron of the present invention comprises the following steps:

[0023] The first step is to carry out aluminizing treatment on the ductile iron workpiece, and obtain an aluminized workpiece after cooling. The aluminizing temperature is 780-850 ° C, and the temperature is kept at this temperature for 2-5 hours;

[0024] In the second step, the aluminized workpiece obtained in the first step is subjected to high-temperature oxidation treatment, and the high-temperature oxidation temperature is 900-1000° C., and kept at this temperature for 2-5 hours.

[0025] The method of the present invention is further characterized in that the mass percentage of the aluminizing agent used in the aluminizing treatment is composed of: aluminum powder 20-30%; ammonium chloride 1-3%; graphite 2-5%; cerium oxide 1-3% %; the balance of alumina.

[0026] The further feature of the method of the p...

Embodiment 1

[0029] figure 1 It is a schematic flow chart of a method for preparing a wear-resistant coating on the surface of a nodular cast iron provided in Example 1 of the present invention. This embodiment is applicable to the case where a wear-resistant coating is prepared on the surface of a nodular cast iron workpiece, and aluminized treatment is performed on the nodular cast iron workpiece , to obtain an aluminized workpiece, and perform high-temperature oxidation treatment on the obtained aluminized workpiece. Such as figure 1 As shown, the technical solution provided by this embodiment is specifically as follows:

[0030] S110, performing aluminizing treatment on the nodular cast iron workpiece, and obtaining an aluminized workpiece after cooling.

[0031] Exemplarily, nodular cast iron has a wide range of applications in automobiles, such as gears, bushings, brakes, etc., and this embodiment uses a valve guide as an example for illustration. Specifically, the aluminizing tre...

Embodiment 2

[0038] The preparation method of the wear-resistant coating on the surface of ductile iron of the present embodiment, the method comprises the following steps:

[0039] The first step, aluminizing treatment: in the aluminizing tank, the ductile iron workpiece is coated with an aluminizing agent; after sealing, the temperature is raised to the first preset temperature, and the temperature is kept for the first preset time, and the first preset The temperature is 780-850° C., the first preset time is 2-5 hours, and an aluminized workpiece is obtained after cooling.

[0040] Exemplarily, the ductile iron workpiece in this embodiment is described by taking the valve guide as an example. The first preset temperature refers to the temperature to which the aluminized tank is heated during the aluminizing process, which is 780-850°C. When heated at this temperature, the aluminizing agent reacts to generate active Al atoms, active Al atoms and matrix Diffusion of Fe atoms in the valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| L | aaaaa | aaaaa |

| L | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com