Automatic speed measuring heating oil conveying pipeline for oil tank truck

A technology for oil pipelines and oil tankers, applied in the direction of thermal insulation protection of pipelines, pipeline protection, pipeline systems, etc., can solve the problems of inability to accurately grasp the heating pipeline parts, waste of resources, etc., and achieve excellent tensile strength and extended use. Longevity and the effect of preventing oxidation of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

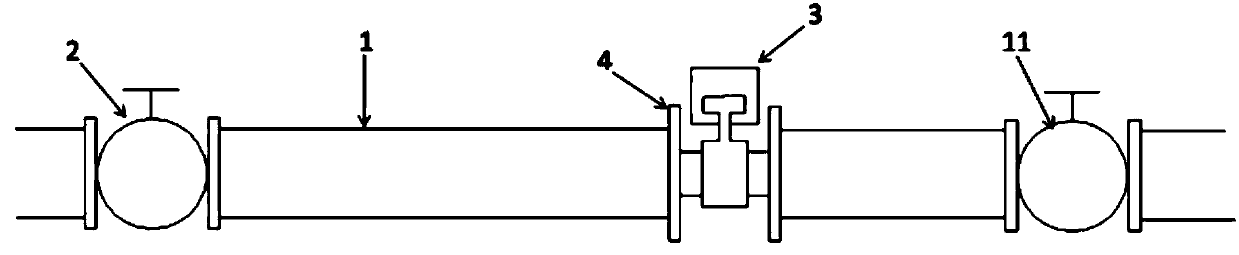

[0030] This embodiment provides a heating oil pipeline for automatic speed measurement of tank trucks, such as figure 1 , is the overall structural diagram of the oil pipeline, the oil pipeline includes pipelines, upstream valves, downstream valves, flanges, and turbine flowmeters; the valves are installed at the joints of the oil pipelines, and the turbine flowmeters are connected to the oil pipelines with flanges. When the oil circulates inside the oil pipeline, the turbine flowmeter can immediately measure the flow velocity of the oil, so as to judge whether the viscosity of the oil in the pipeline is too high and the flow velocity becomes low.

[0031] Further, the turbine flowmeter is installed between two valves, the diameter of the pipe is D, the distance from the upstream valve is at least 10D, and the distance from the downstream valve is at least 5D. Only by keeping enough distance can the specific flow rate of this section be accurately measured.

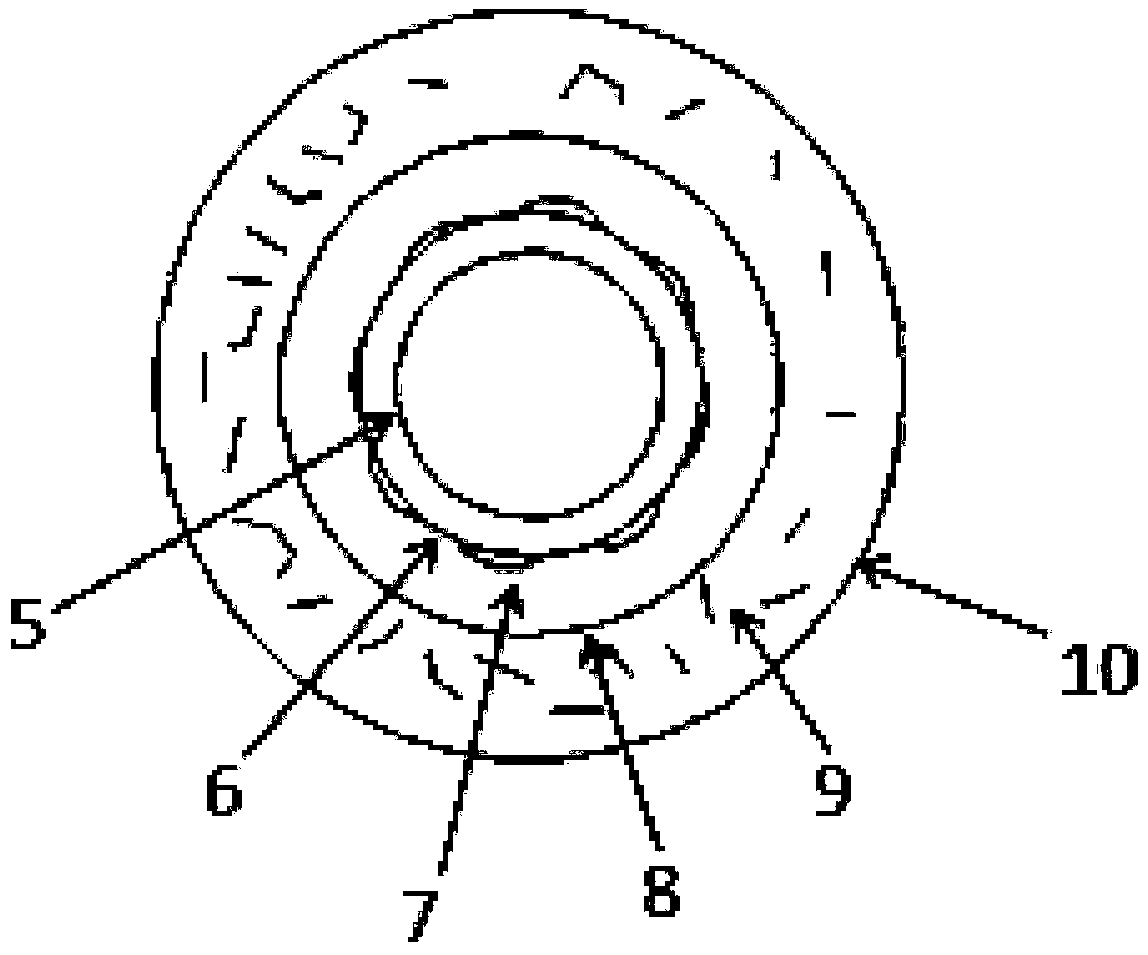

[0032] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com