High-quality waste heat recovery anticorrosion device and working method thereof

A waste heat recovery and working method technology, which is applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve the effects of improving corrosion resistance, improving desulfurization effect, and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

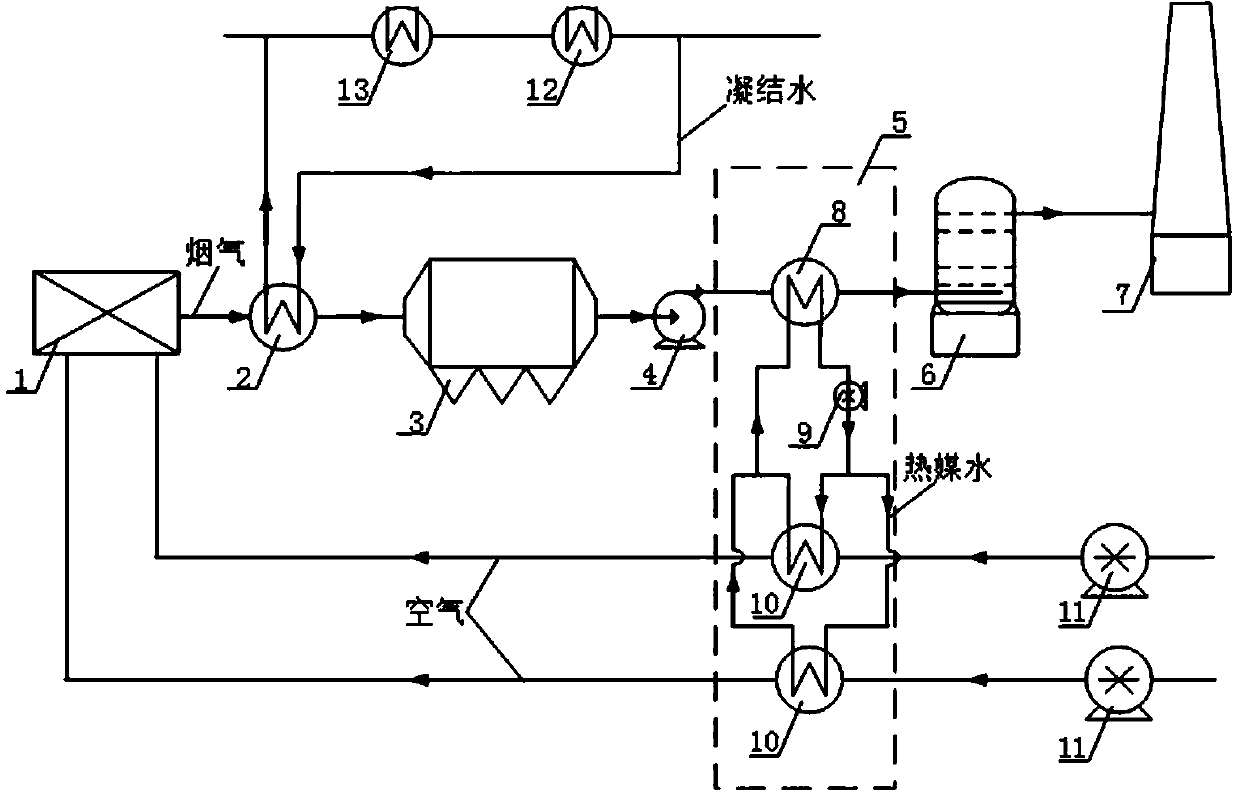

[0027] see figure 1 .

[0028] This embodiment is a high-quality waste heat recovery anti-corrosion device, including air preheater system 1, high-quality waste heat recovery and utilization system 2, dry dust removal system 3, induced draft fan 4, deep waste heat recovery air preheating system 5, high-efficiency desulfurization Dust removal system 6, chimney 7, low-level addition system 12 at the next level, low-level addition system 13 at the upper level, and primary fan 11 (supply fan).

[0029] Air preheater system 1, high-quality waste heat recovery and utilization system 2, dry dust removal system 3, induced draft fan 4, deep waste heat recovery air preheating system 5, high-efficiency desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com