A two-component antibacterial and antifouling epoxy beautifying agent and its preparation method

A two-component, beauty joint technology, used in epoxy resin coatings, antifouling/underwater coatings, and biocide-containing paints, etc., can solve problems such as failure to maintain beauty for a long time, damage to human health, and cumbersome construction procedures. , to achieve lasting antibacterial and antifungal effects, not easy to wash off, and lasting antibacterial and antifungal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the above-mentioned two-component antibacterial and antifouling epoxy beautifying agent comprises the following steps:

[0059] 1) Mix epoxy resin and antibacterial and antifouling additives evenly, react at 50-100°C for 1-3 hours, add thixotropic agent, defoamer and leveling agent, and mix evenly to obtain component A;

[0060] 2) Mix epoxy resin, epoxy resin curing agent, pigment, thixotropic agent, defoamer and leveling agent evenly until the viscosity is constant to obtain component B;

[0061] 3) When using for construction, mix components A and B evenly.

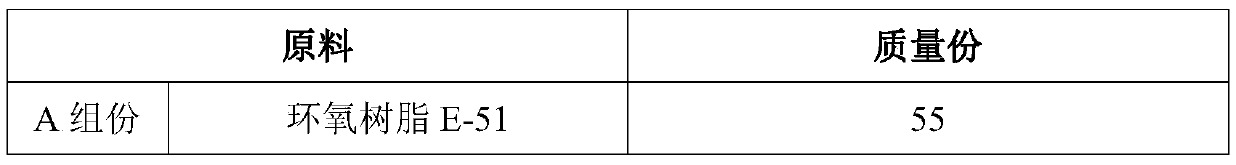

Embodiment 1

[0064] A two-component antibacterial and antifouling epoxy grouting agent, its raw material composition is shown in the following table:

[0065] Table 1 The raw material composition list of a kind of two-component antibacterial and antifouling epoxy beautifying agent

[0066]

[0067] Wherein, the mass ratio of component A and component B is 1:1.

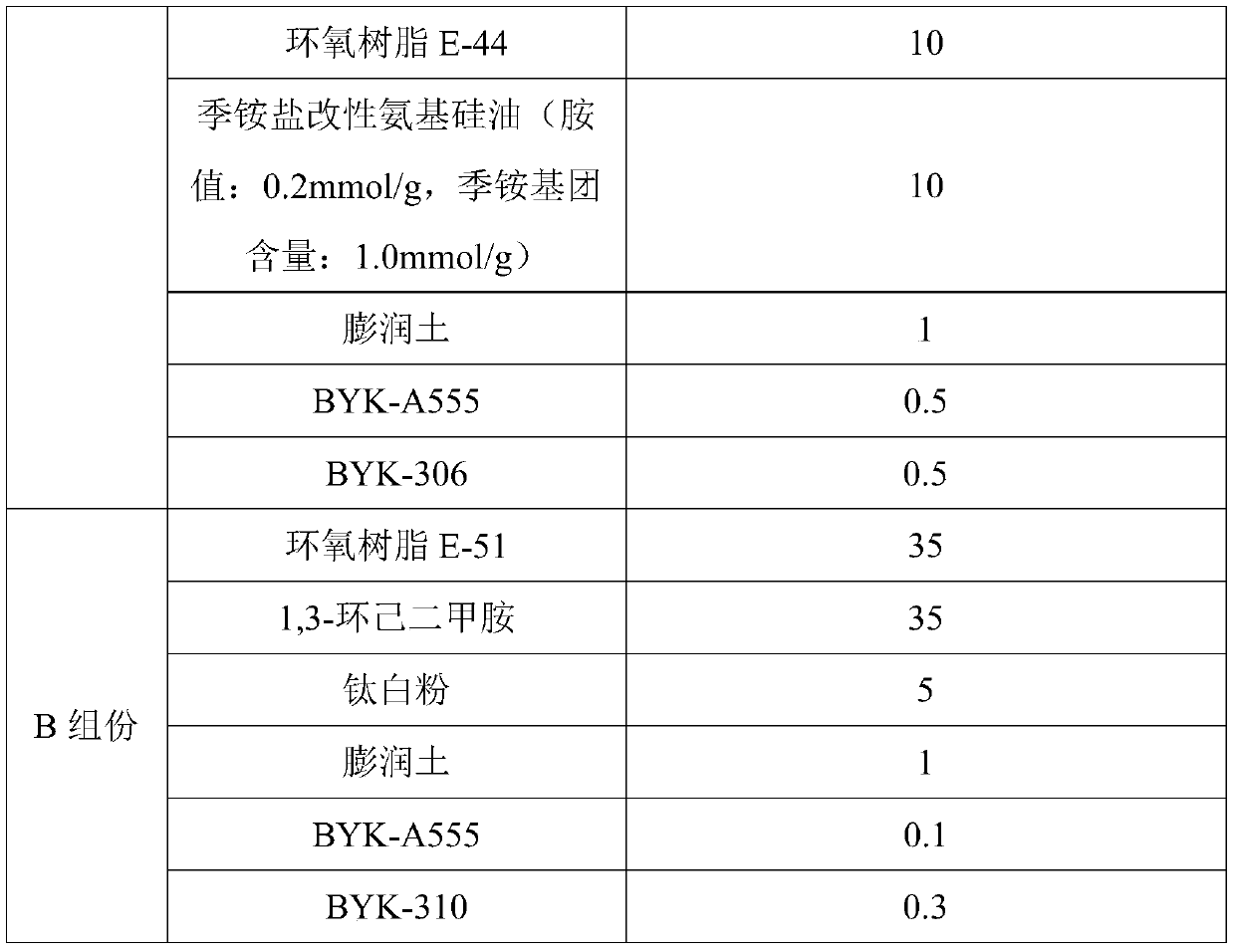

Embodiment 2

[0069] A two-component antibacterial and antifouling epoxy grouting agent, its raw material composition is shown in the following table:

[0070] Table 2 The raw material composition list of a kind of two-component antibacterial and antifouling epoxy beauty joint agent

[0071]

[0072]

[0073] Wherein, the mass ratio of component A and component B is 1:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com