Spiral steel pipe inner weld seam scraper

A technology of spiral steel pipe and scraper, which is applied in the field of cutting tools, can solve the problems of high noise, low efficiency, and inability to remove welding slag, and achieve the effects of low noise, high removal rate of welding slag, and improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

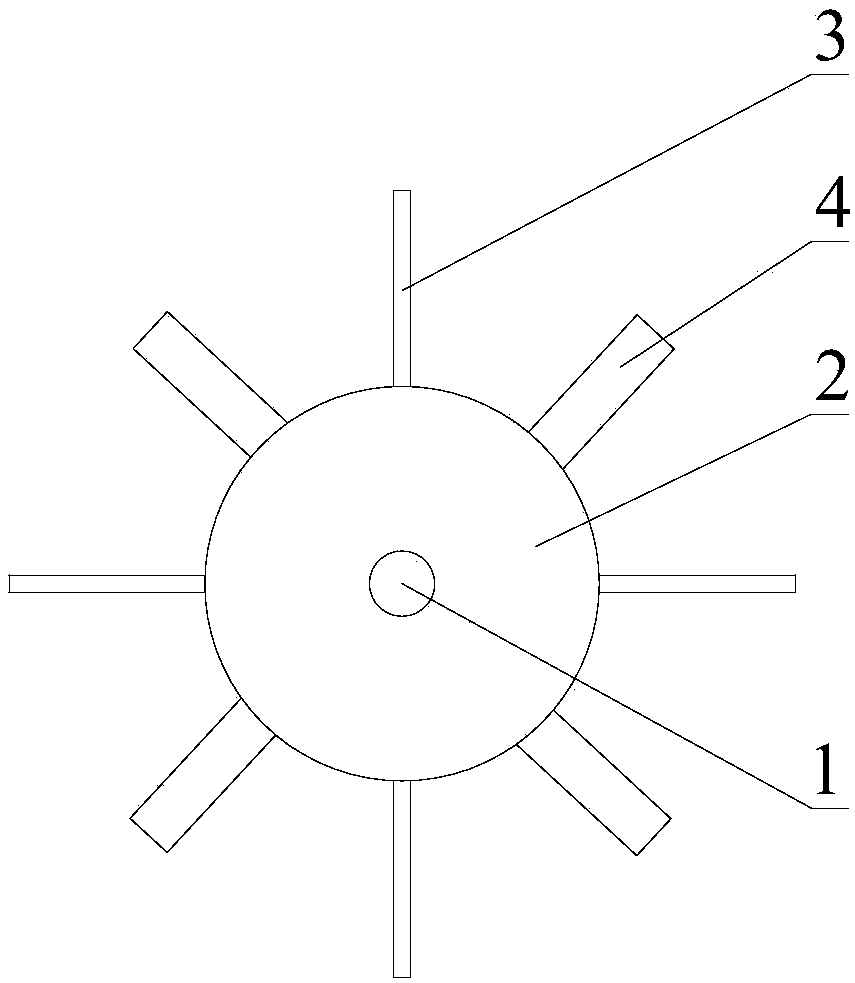

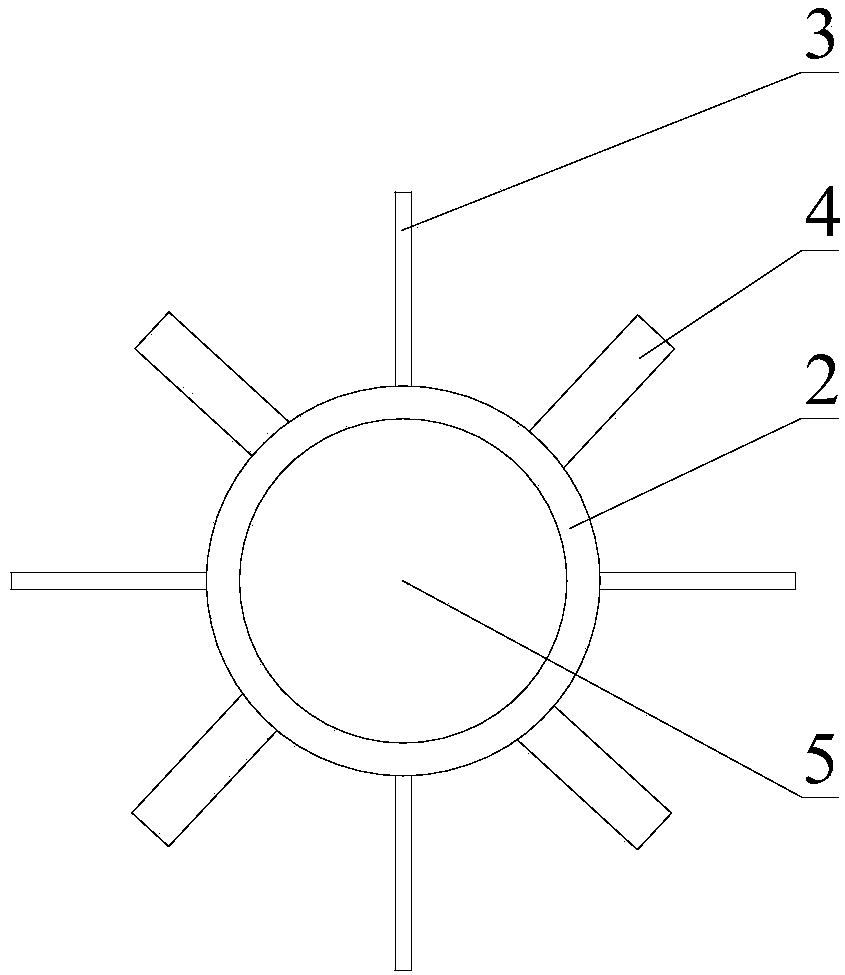

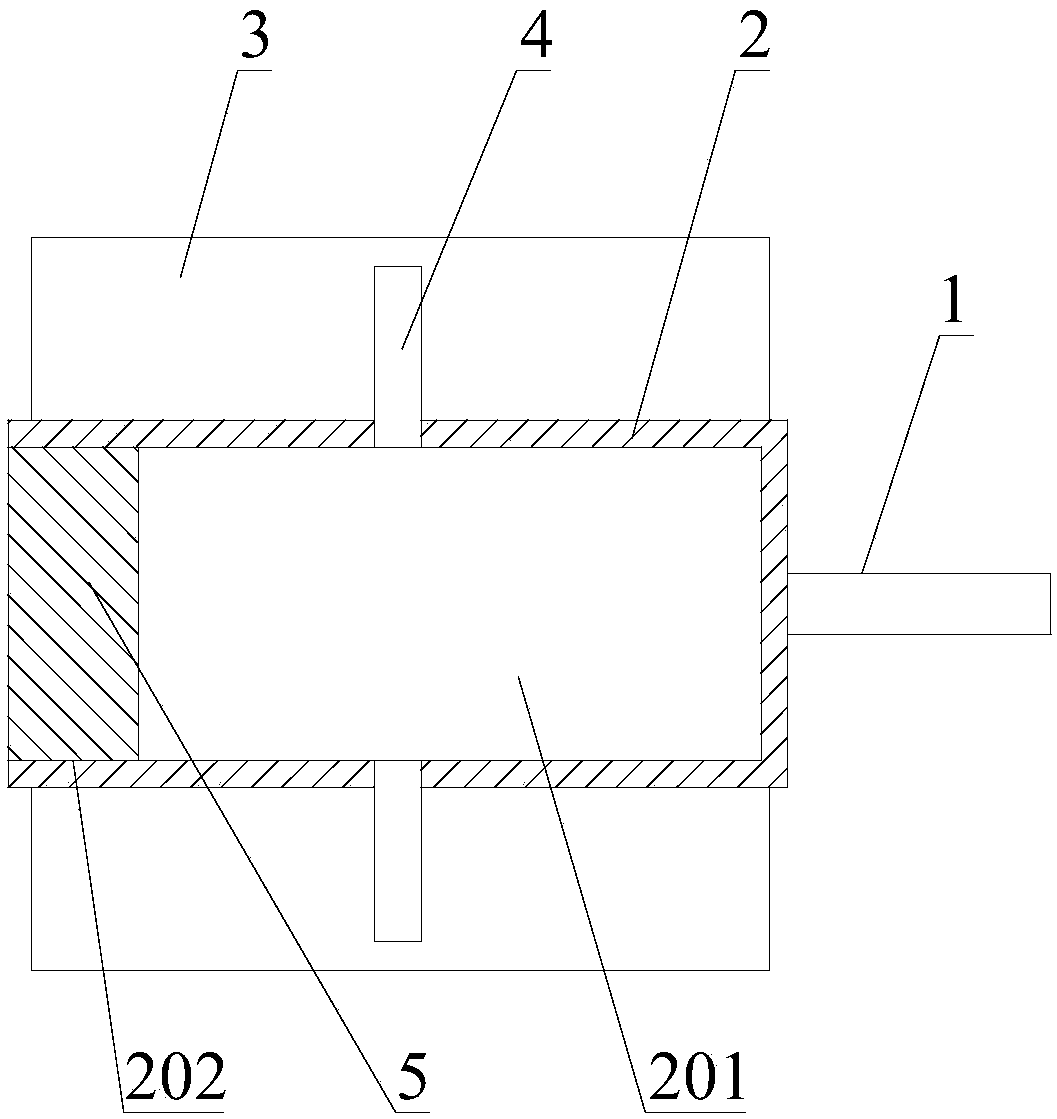

[0024] Such as Figure 1 to Figure 4 As shown, the inner weld seam scraper of the spiral steel pipe includes a driving rod 1, a rotating column 2, a blade 3, a cooling pipe 4 and a plug 5; the rear end of the driving rod 1 is connected to the front end of the rotating column 2, and the driving rod 1 is connected to the rotating The column 2 is coaxially arranged, and several blades 3 are evenly arranged on the outer peripheral surface of the rotating column 2, and the blades 3 are parallel to the central axis of the rotating column 2; The end is provided with an opening 202 communicating with the liquid storage cavity 201, and the plug 5 is detachably fixed in the opening 202; the two ends of the cooling pipe 4 are open, and one end of the cooling pipe 4 is fixed on the outer peripheral surface of the rotating column 2, and the cooling pipe 4 4 communicates with the liquid storage cavity 201.

[0025] In this embodiment, the plug 5 can be fixed in the opening 202 through scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com