Ceramic tile for purifying air and humidifying and preparation method thereof

A technology for purifying air and ceramic tiles, applied in the field of architectural ceramics, can solve the problems of poor bonding between photocatalytic films and ceramic substrates, uneven distribution of photocatalysts, and affecting the aesthetics of ceramics, and achieve excellent photocatalytic degradation of toxic gases. Large-scale industrial production and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

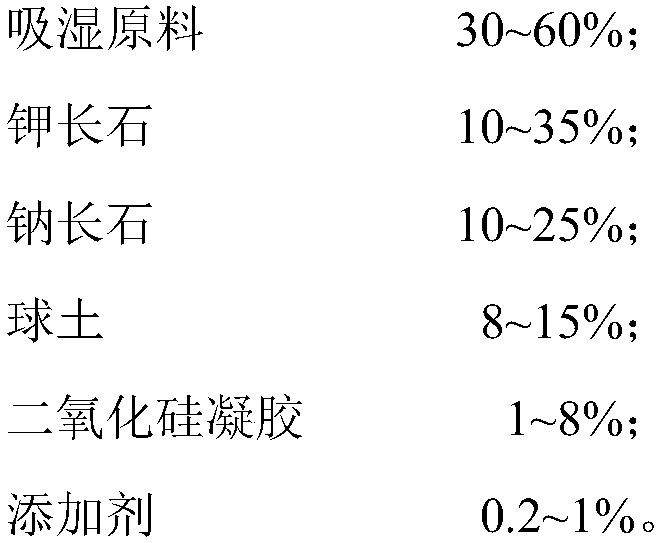

[0031] An air-purifying and humidity-regulating ceramic tile comprises, from bottom to top, a nanoporous body layer, a decorative pattern layer, a nanometer photocatalytic material layer and a low-temperature thin glaze layer, wherein the low-temperature thin glaze layer has a porous structure or a crack structure.

[0032] Wherein, the nanoporous green body layer has the following components in weight percentage of raw materials: 30% diatomite, 25% potassium feldspar, 25% albite, 11.8% ball earth, 8% dioxide Silicone gel, 0.2% polyacrylic acid.

[0033] The nanometer photocatalytic material layer is a nanometer titanium dioxide layer.

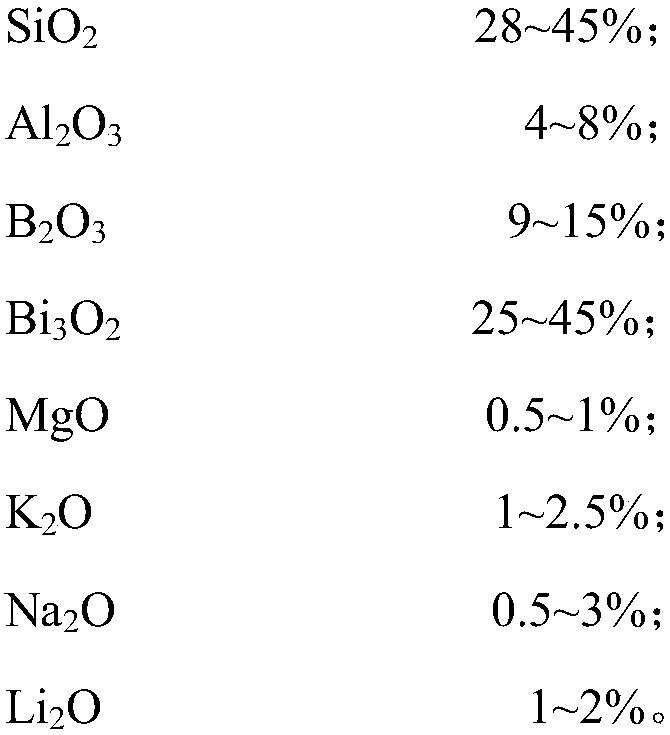

[0034] The low-temperature thin glaze layer includes the following chemical composition by weight: 28% SiO 2 , 8% Al 2 O 3 , 13.5% B 2 O 3 , 45% Bi 3 O 2 , 0.5% MgO, 2.5% K 2 O, 0.5% Na 2 O and 2% Li 2 O.

[0035] Preparation:

[0036] 1) Put each raw material component of the nanoporous green body together with water in a ball mil...

Embodiment 2

[0042] An air-purifying and humidity-regulating ceramic tile comprises, from bottom to top, a nanoporous body layer, a decorative pattern layer, a nanometer photocatalytic material layer and a low-temperature thin glaze layer, wherein the low-temperature thin glaze layer has a porous structure or a crack structure.

[0043] The nanoporous green body layer has the following components in terms of weight percentage of raw materials: 60% of zeolite, 10% of potassium feldspar, 13% of albite, 15% of ball clay, 1% of silica agglomerate glue, 1% sodium tripolyphosphate.

[0044]The nano-photocatalytic material layer is lanthanum-doped nano-titanium dioxide.

[0045] The low-temperature thin glaze layer includes the following chemical composition by weight: 45% SiO 2 , 4% Al 2 O 3 , 15% B 2 O 3 , 31.5% Bi 3 O 2 , 0.5% MgO, 2.5% K 2 O, 0.5% Na 2 O and 1% Li 2 O.

[0046] Preparation:

[0047] 1) Put each raw material component of the nanoporous green body together with wate...

Embodiment 3

[0053] An air-purifying and humidity-regulating ceramic tile comprises, from bottom to top, a nanoporous body layer, a decorative pattern layer, a nanometer photocatalytic material layer and a low-temperature thin glaze layer, wherein the low-temperature thin glaze layer has a porous structure or a crack structure.

[0054] Wherein, the nanoporous green body layer has the following components in terms of weight percentage of raw materials: 45% sepiolite, 35% potassium feldspar, 10% albite, 8% ball clay, 1% carbon dioxide Silicone gel, 1% carboxymethyl cellulose.

[0055] The nano-photocatalytic material layer is neodymium-doped nano-titanium dioxide.

[0056] The low-temperature thin glaze layer includes the following chemical composition by weight: 43.5% SiO 2 , 8% Al 2 O 3 , 15% B 2 O 3 , 25% Bi 3 O 2 , 1% MgO, 2.5% K 2 O, 3% Na 2 O and 2% Li 2 O.

[0057] Preparation:

[0058] 1) Put each raw material component of the nanoporous green body together with water in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com