Ageing-resistant shock-absorption styrene butadiene rubber material

A styrene-butadiene rubber, anti-aging technology, applied in the field of styrene-butadiene rubber, can solve the problems of thermal oxygen aging resistance, poor ozone aging resistance, easy aging failure, easy aging and other problems, and achieve good damping and shock absorption effect, anti-aging Strong precipitation ability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An aging-resistant shock-absorbing styrene-butadiene rubber material, comprising the following components in parts by weight: styrene-butadiene rubber 60, natural rubber 45, N774 carbon black 16, modified light calcium 110, naphthenic oil 4010 85, antioxidant HS911 1.2 , Antiager MB 1.2, Zinc Oxide 7, Stearic Acid 1.6, Microcrystalline Wax 1.5, Sulfur 0.65, Accelerator 5.5.

[0015] Wherein the accelerator comprises 1.5 parts of accelerator DM, 1 part of accelerator M, 2 parts of accelerator TETD, and 1 part of accelerator CBS.

[0016] Wherein the modified light calcium is surface-coated light calcium containing propyl gallate, with an average particle diameter of 500nm, wherein the weight ratio of light calcium to propyl gallate is 1:0.001, and the surface coating process is fluidized in a bed reactor.

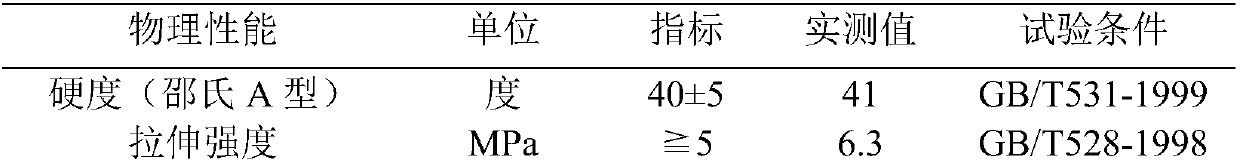

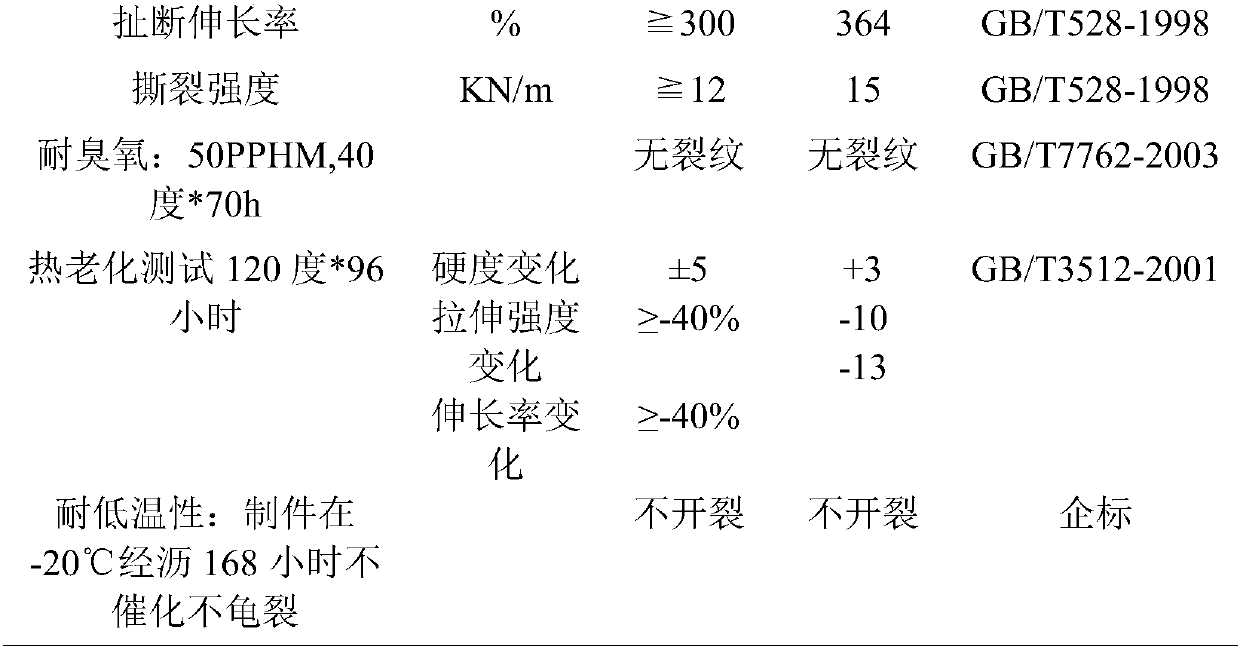

[0017] The prepared materials were tested for various properties according to the corresponding national standards, and the experimental data are shown in Table 1: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com