Recycling device and method of waste polyester filaments

A technology of recycling and waste silk, applied in the field of polyester fiber manufacturing, can solve the problems of large batch viscosity difference, high labor intensity, complex chemical process, etc., to improve the quality of regenerated fibers and solve the effect of huge pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

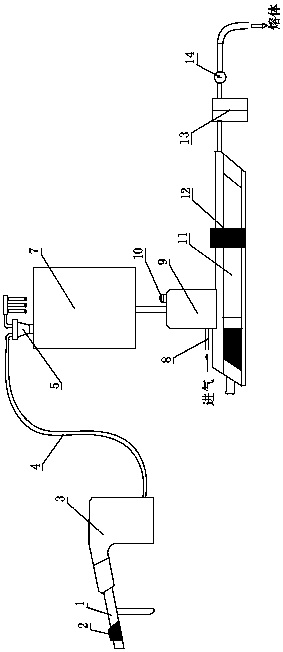

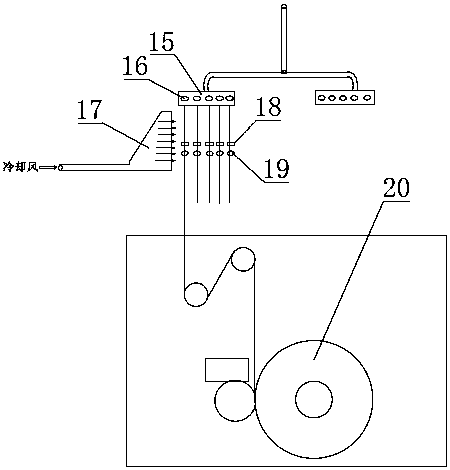

[0021] Such as figure 1 As shown, a recycling equipment for polyester waste silk described in this embodiment includes a metal detection unit, a crushing unit, a purification separation unit, an extrusion unit, a vacuum unit 12, a melt filtration unit 13 and a booster connected in sequence. The pressure unit 14, the booster unit 14 outputs the melt to the spinning equipment. The metal detection unit described herein is a metal detector 2, the crushing unit is a pulverizer 3, the purification and separation unit is a cyclone separator 5 and a cutting compactor 9, and the extrusion unit is an extruder 11, wherein the pulverizer 3 is transported Belt 1 inputs polyester waste silk, the metal detector 2 is arranged on the conveyor belt 1, the pulverizer 3 is connected to the buffer storage bin 7 through the pipeline 4, and the described cyclone separator 5 is arranged on the top of the buffer storage bin 7 , the lower end of the buffer storage bin 7 is connected with the cutting c...

Embodiment 2

[0023] This embodiment describes the use of melt direct spinning waste silk as raw material, recycling it to produce POY products, the fineness is 155 dtex, and the number of holes is 36. The preparation method of the product is divided into the following two steps:

[0024] 1. Preparation of spinning melt;

[0025] Such as figure 1 As shown, the winding waste silk containing oil agent or the spinning waste silk without oil agent is first conveyed to the pulverizer 3 by means of the conveyor belt 1, and the metal detector 2 is installed on the conveyor belt 1, and the metal detector 2 is passed through the metal detector 2 to remove it. Metal debris such as hook knives, tools, etc.; the waste wire is crushed into a substantially consistent size in the shredder 3; it is sent to the buffer bin 7 through the pipeline 4, and a cyclone separator 5 is installed on the top of the buffer bin 7 to remove Dust, granular impurities; then enter the cutting and compacting machine 9, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com