Ultra-high performance concrete slab seam connecting structure and construction method thereof

An ultra-high performance, concrete slab technology, applied in building components, building structures, building thermal insulation materials, etc. seam size and other issues, to achieve good economic benefits, avoid disease problems, and reduce the weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

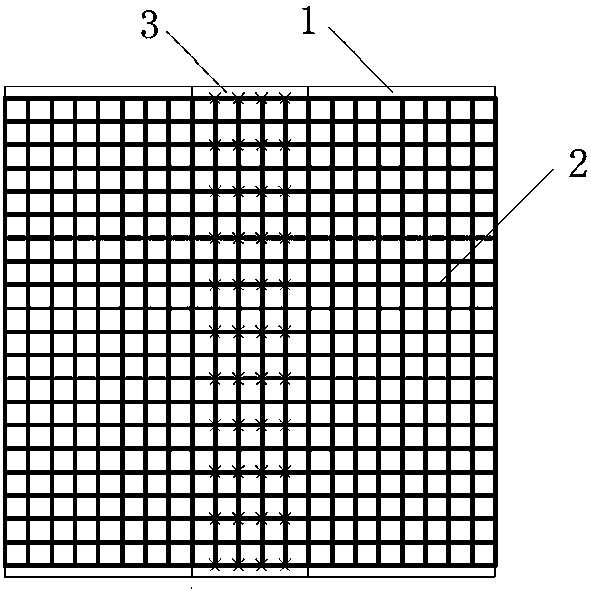

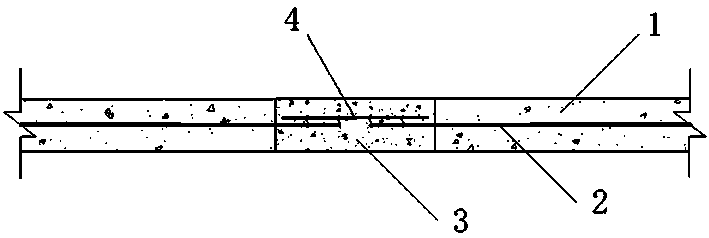

[0020] Embodiment 1: as Figure 1~2 As shown, a joint connection structure of ultra-high performance concrete slabs includes two ultra-high performance concrete slabs 1 located on the same plane, and there is a cast-in-place joint in the middle of the two ultra-high performance concrete slabs 1, and each ultra-high performance concrete slab There is a high-strength steel wire mesh 2 inside the slab, and the side of the high-strength steel wire mesh 2 facing the cast-in-place joint passes through the same side of the ultra-high performance concrete slab and extends into the cast-in-place joint, and the protruding parts of the high-strength steel wire mesh on both sides pass through A high-strength steel wire mesh is connected together, and an ultra-high-performance concrete joint plate 3 connecting the ultra-high-performance concrete slabs on both sides is poured in the cast-in-place joint; the structure has high strength, excellent durability, and reasonable force. In line wit...

Embodiment 2

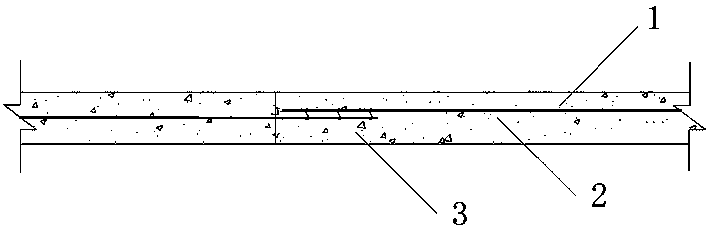

[0029] Embodiment 2: as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the ultra-high performance concrete slab in this embodiment is a cast-in-place concrete slab, that is, two ultra-high-performance concrete slabs 1 are close together, and there is no cast-in-place joint.

[0030] In this embodiment, among two adjacent ultra-high-performance concrete slabs, the high-strength steel wire mesh of one of them extends into the other ultra-high-performance concrete slab 1 and is stacked with its high-strength steel mesh and fixed by binding and welding Or the equipment is connected and fixed; when casting on site, one of the ultra-high performance concrete slabs is poured first, and then another ultra-high performance concrete slab is poured. The high-strength steel wire mesh on the ultra-high performance concrete slab poured first extends a certain length It is stacked with the high-strength steel wire mesh on the post-cast ultra-high performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com