High-toughness polypropylene plastic, and preparation method and applications thereof

A polypropylene plastic, high toughness technology, applied in the field of plastic hard packaging, can solve problems such as agglomeration and uneven matrix distribution, and achieve the effects of low viscosity, high light transmittance, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1

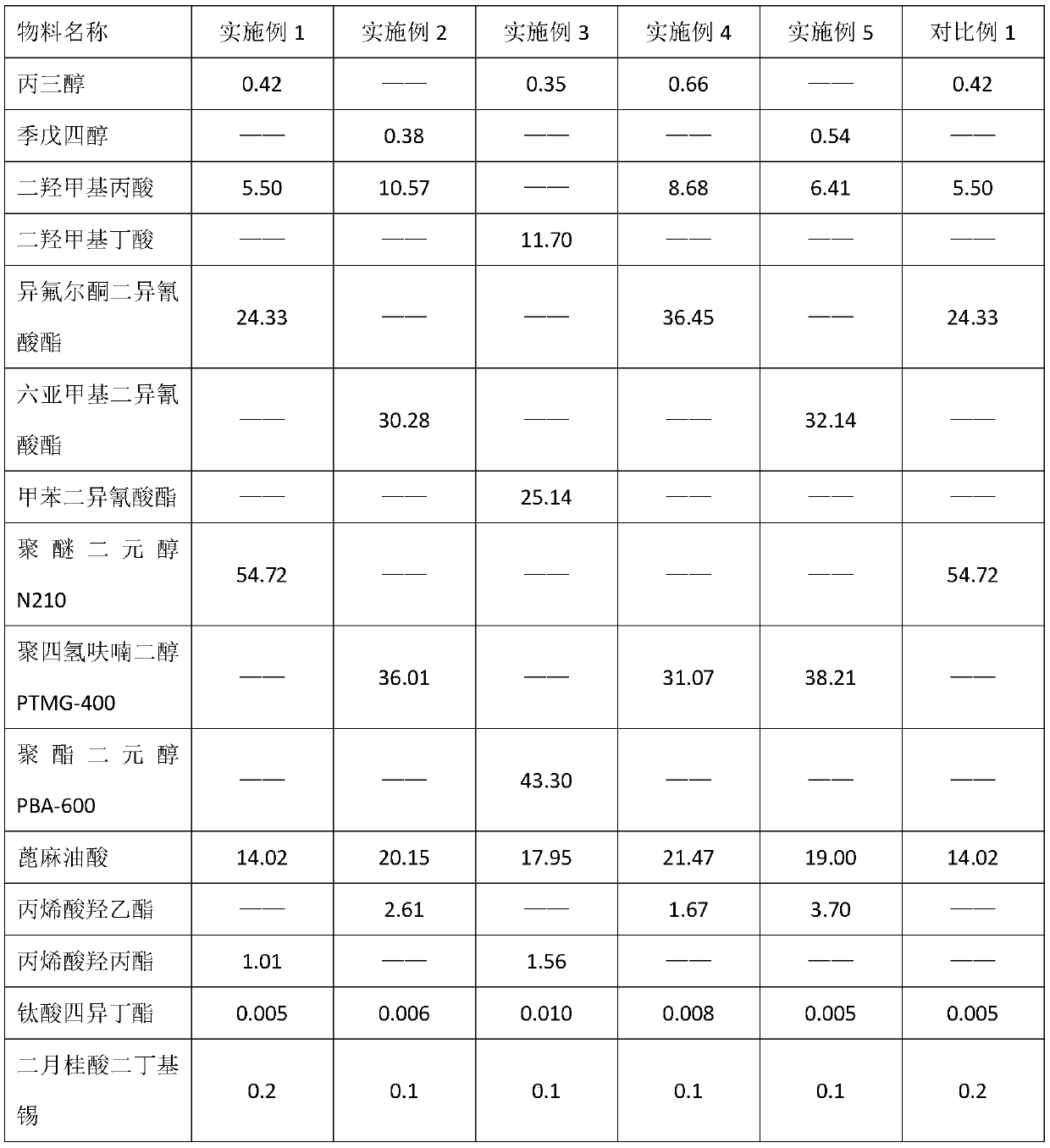

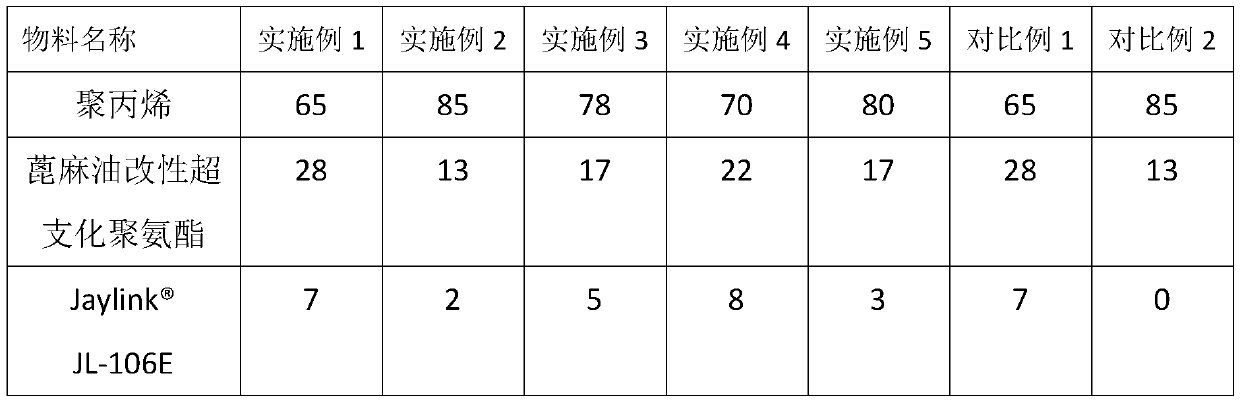

[0048] Embodiments 1 to 5 and comparative example 1 were prepared according to the above method, wherein the raw material addition amount of castor oil modified hyperbranched polyurethane is as shown in Table 1; the polypropylene plastics and PP plastics of embodiments 1 to 5 and comparative examples 1 to 2 The raw material addition of thin-walled plastic container is as shown in table 2;

[0049] Table 1 (raw material addition, unit: g)

[0050]

[0051] Table 2 (raw material addition, unit: g)

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com