Hole interior variable-frequency vibration anti-reflection gas extraction method and device

A technology of variable frequency vibration and gas extraction, which is applied in vibration generating devices, gas discharge, safety devices, etc., can solve the problems of low extraction efficiency, limited application scope, pollution, etc., and achieve the effect of broadening the application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

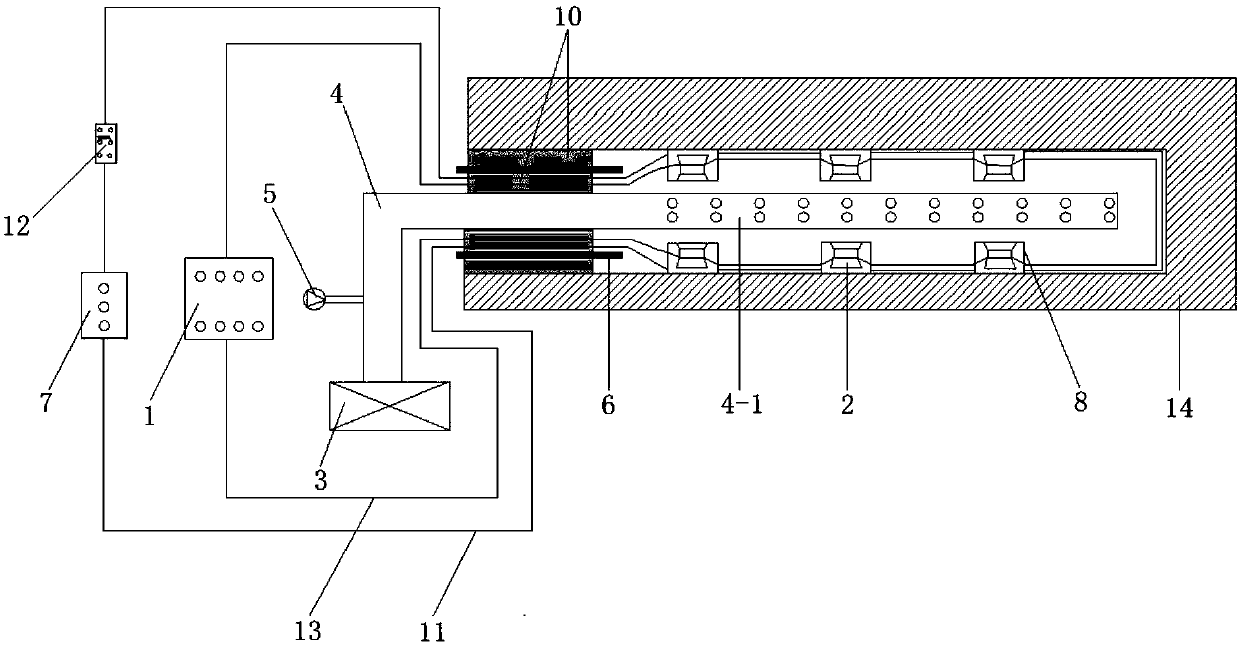

[0034] In this embodiment, the structural diagram of the anti-reflection gas drainage device with frequency conversion vibration in the hole is as follows Figure 1-2 As shown, the figure is a schematic diagram of the working state of 1 gas drainage, figure 2 It is a schematic diagram of the device installed in the borehole.

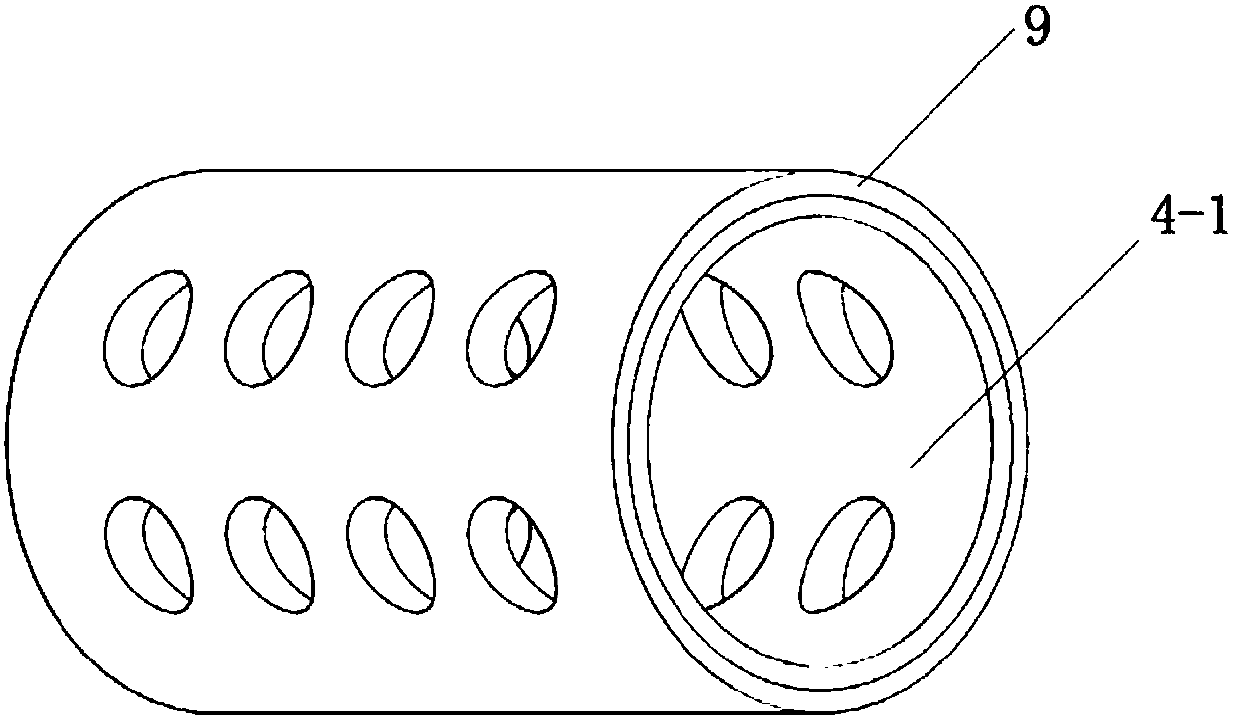

[0035] The in-hole frequency conversion vibration anti-reflection gas drainage device provided in this embodiment includes a frequency conversion ultrasonic generator 1, 6 ultrasonic transducers 2, a gas drainage pump 3, a gas drainage pipe 4, and a gas flow meter 5, The sealing pipe 6, the electric control box 7, the installation shell 8, the ultrasonic transducer is located in the borehole, and the ultrasonic generator, electric control box, gas extraction pump and gas flow meter are located in the roadway outside the borehole.

[0036] The borehole is located in the coal seam 14 to be treated for gas and is set horizontally. The outer diameter of th...

Embodiment 2

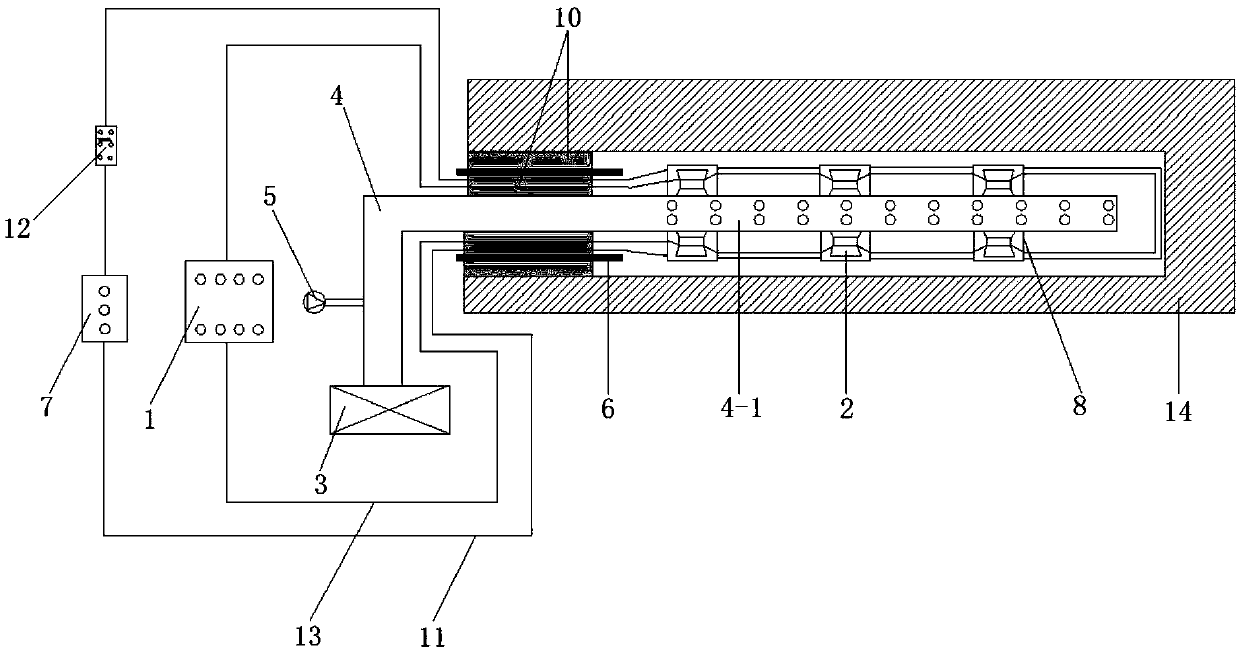

[0045] In this embodiment, the structural diagram of the anti-reflection gas drainage device with frequency conversion vibration in the hole is similar to that shown in Figure 1-2 As shown, the figure is a schematic diagram of the working state of 1 gas drainage, figure 2 It is a schematic diagram of the device installed in the borehole.

[0046] The in-hole frequency conversion vibration anti-reflection gas extraction device provided in this embodiment includes a frequency conversion ultrasonic generator 1, 4 ultrasonic transducers 2, a gas extraction pump 3, a gas extraction pipe 4, and a gas flow meter 5, The sealing pipe 6, the electric control box 7, the installation shell 8, the ultrasonic transducer is located in the borehole, and the ultrasonic generator, electric control box, gas extraction pump and gas flow meter are located in the roadway outside the borehole.

[0047] The borehole is located in the coal seam 14 to be treated for gas. The borehole is set up obliq...

Embodiment 3

[0056] In this embodiment, the structural diagram of the anti-reflection gas drainage device with frequency conversion vibration in the hole is similar to that shown in Figure 1-2 As shown, the figure is a schematic diagram of the working state of 1 gas drainage, figure 2 It is a schematic diagram of the device installed in the borehole.

[0057] The in-hole frequency conversion vibration anti-reflection gas extraction device provided in this embodiment includes a frequency conversion ultrasonic generator 1, 10 ultrasonic transducers 2, a gas extraction pump 3, a gas extraction pipe 4, and a gas flow meter 5, The sealing pipe 6, the electric control box 7, the installation shell 8, the ultrasonic transducer is located in the borehole, and the ultrasonic generator, electric control box, gas extraction pump and gas flow meter are located in the roadway outside the borehole.

[0058] The borehole is located in the coal seam 14 to be treated for gas. The borehole is set oblique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com