Dried mango making method

A technology of dried mangoes and mangoes, applied in confectionary, confectionary industry, food science, etc., can solve problems such as drying firepower, difficulty in time control, loss of nutrients, fading of mango color, aroma, and taste, etc., and achieve shortening Effect of drying time, slowing down of oxidative damage, reduction of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

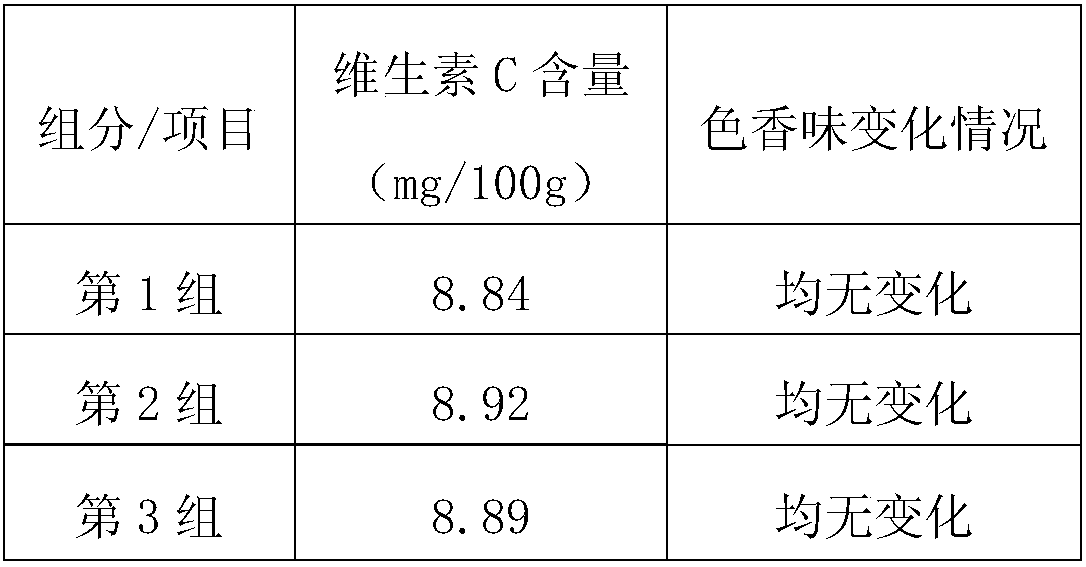

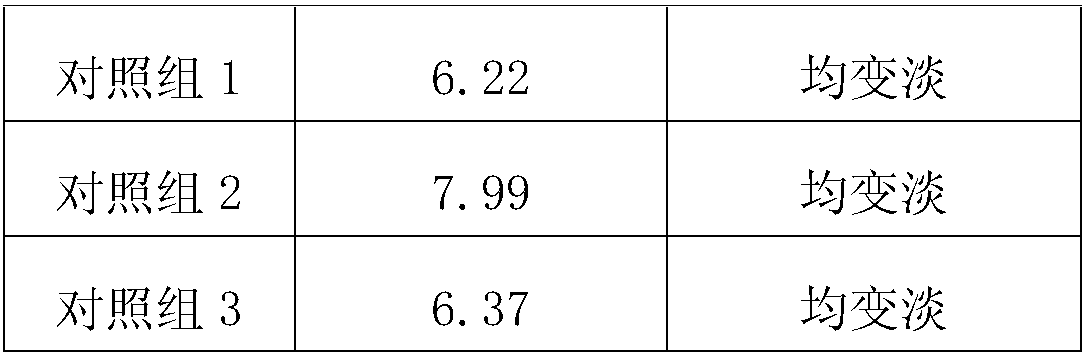

Embodiment 1

[0023] A kind of preparation method of dried mango of the present embodiment comprises the following steps:

[0024] (1) Raw material selection: select 3-5 ripe fresh mangoes without pests and diseases, without mechanical damage, and set aside;

[0025] (2) Raw material pretreatment: Pour the above-mentioned fresh mango into running water to remove sediment and dirt, peel and core, cut into mango slices with a thickness of 0.8-1.0cm, and immediately soak in the color protection solution for 1min , to obtain color-protecting mango slices, the color-protecting solution is mixed with salt, tea polyphenols and water in a weight ratio of 1:0.5:100;

[0026] (3) Sugaring: put the above-mentioned color-protecting mango slices into 15% sucrose solution at 25° C. and soak for 20-24 hours, drain to obtain candied mango slices, and set aside;

[0027] (4) Far-infrared drying: spread the above-mentioned candied mango slices one by one on the grid tray, and dry them in a far-infrared dryi...

Embodiment 2

[0031] A kind of preparation method of dried mango of the present embodiment comprises the following steps:

[0032] (1) Raw material selection: select 3-5 ripe fresh mangoes without pests and diseases, without mechanical damage, and set aside;

[0033] (2) Raw material pretreatment: Pour the above-mentioned fresh mango into running water to remove sediment and dirt, peel and core, cut into mango slices with a thickness of 0.8-1.0cm, and immediately soak in the color protection solution for 3 minutes , to obtain color-protecting mango slices, the color-protecting solution is mixed with salt, tea polyphenols and water in a weight ratio of 2:0.8:100;

[0034] (3) Candied: Put the above-mentioned color-protecting mango slices into 25% maltose solution at 30°C and soak for 24 hours, drain to obtain candied mango slices, set aside;

[0035] (4) Far-infrared drying: Spread the above-mentioned candied mango slices one by one on a grid tray, and dry them in a far-infrared drying oven...

Embodiment 3

[0039] A kind of preparation method of dried mango of the present embodiment comprises the following steps:

[0040] (1) Raw material selection: select 3-5 ripe fresh mangoes without pests and diseases, without mechanical damage, and set aside;

[0041] (2) Raw material pretreatment: Pour the above-mentioned fresh mango into running water to remove sediment and dirt, peel and core, cut into mango slices with a thickness of 0.8-1.0cm, and immediately soak in the color protection solution for 2 minutes , to obtain color-protecting mango slices, the color-protecting solution is mixed with salt, tea polyphenols and water in a weight ratio of 1.5:0.6:100;

[0042] (3) Candied: Put the above-mentioned color-protecting mango slices into 20% fructose solution at 28°C and soak for 23 hours, drain to obtain candied mango slices, set aside;

[0043] (4) Far-infrared drying: Spread the above-mentioned candied mango slices one by one on a grid tray, and dry them in a far-infrared drying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com