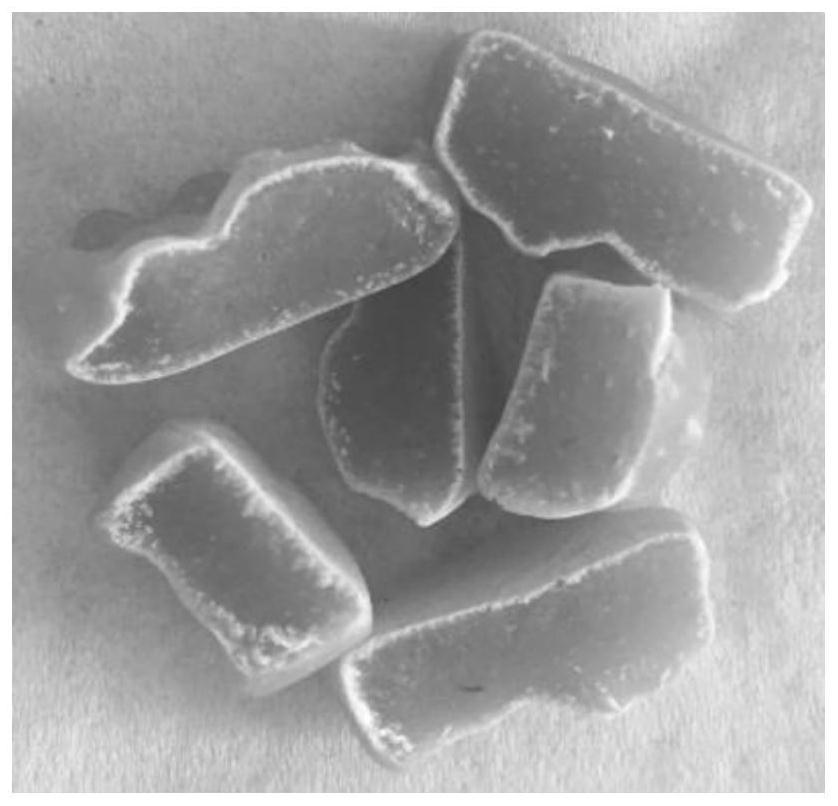

A kind of frosted soft candy with temperature resistance and preparation method thereof

A temperature-resistant, soft candy technology, applied in confectionery, confectionary industry, food science, etc., can solve problems such as sticking, deformation, and softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

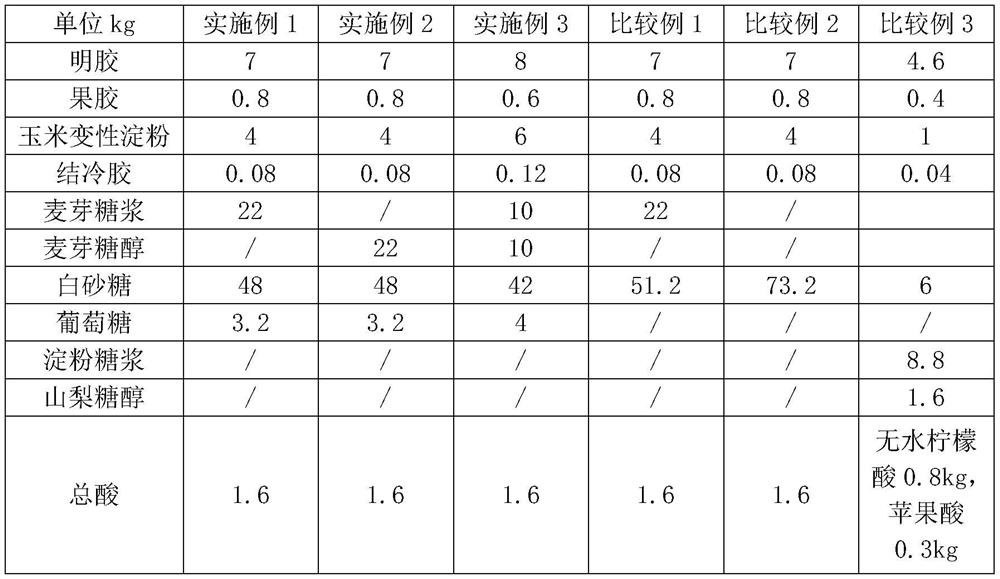

[0118] The recipe for temperature-resistant frosted fudge is:

[0119] Gelatin 7.0kg, pectin 0.8kg, corn modified starch 4.0kg, gellan gum 0.08kg;

[0120] Maltose syrup 22.0kg, white sugar 48.0kg, glucose 3.20kg;

[0121] The total acid is 1.6kg, and the total acid is a mixture of citric acid, DL-malic acid, and buffered lactic acid in a mass ratio of 1.6:0.8:1.

[0122] The preparation method is:

[0123] (1) Glue: Add water 1.5 times the weight of gelatin into the glue tank, heat to 70°C, add gelatin, heat and stir until the gelatin dissolves, and get gelatin solution A, keep it warm at 60°C for later use; pectin, gellan gum and formula A certain amount of glucose was mixed, heated and boiled with purified water 12 times the weight of pectin to obtain glue B;

[0124] (2) Boiling sugar: Weigh maltose syrup and white granulated sugar according to the formula, add 1 / 4 of the weight of white granulated sugar in purified water, heat to boil, then add modified starch disperse...

Embodiment 2

[0129] The preparation method is the same as that in Example 1, except that an equal amount of maltitol is used instead of maltose syrup to prepare temperature-resistant frosted soft candy.

Embodiment 3

[0131] The preparation method is the same as in Example 1, except that the amount of some raw materials is changed, and maltitol and maltose syrup are used at the same time. The formula is shown in Table 1, and the temperature-resistant frosted soft candy is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com