PVC (polyvinyl chloride) decoration plate prepared from acidification modified white ash

A decorative sheet and white soot technology, applied in the field of PVC decorative sheet, can solve the problems of complex composition of soot, environmental pollution, large fluctuation of phase composition, etc., and achieve excellent processability and stability, high economic added value, and wide application. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

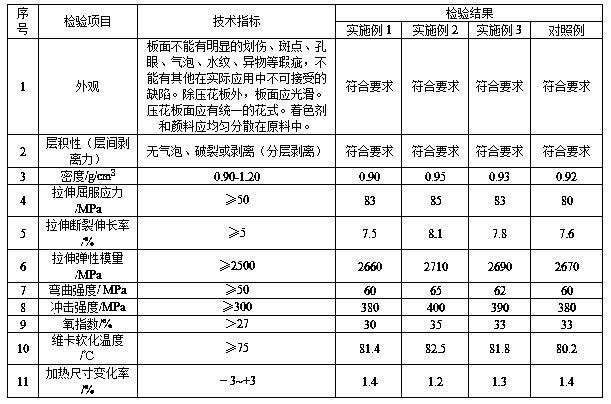

Embodiment 1

[0014] A PVC decorative board made of acidified modified white soot, comprising the following components by weight: 100 parts of PVC, 40 parts of acidified modified white soot composite lead salt, 5 parts of acidified modified white soot composite salt base lead phosphite 5 parts of MBS, 4 parts of CPE, 4 parts of ACR, 1 part of paraffin, 2 parts of barium stearate.

Embodiment 2

[0016] A PVC decorative board made of acidified modified white soot, comprising the following ingredients in proportion by weight: 100 parts of PVC, 70 parts of acidified modified white soot composite lead salt, 10 parts of acidified modified white soot composite salt base lead phosphite parts, MBS 8 parts, CPE 6 parts, ACR 6 parts, paraffin 4 parts, barium stearate 3 parts.

Embodiment 3

[0018] A PVC decorative board made of acidified modified white soot, comprising the following components by weight: 100 parts of PVC, 65 parts of acidified modified white soot composite lead salt, 8 parts of acidified modified white soot composite salt base lead phosphite , 7 parts of MBS, 5 parts of CPE, 5 parts of ACR, 3 parts of paraffin, 3 parts of barium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield stress | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com