optical display device

A technology of diffractive optical elements and gratings, which is applied in the field of augmented reality optical display devices, and can solve problems such as difficult application of coating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

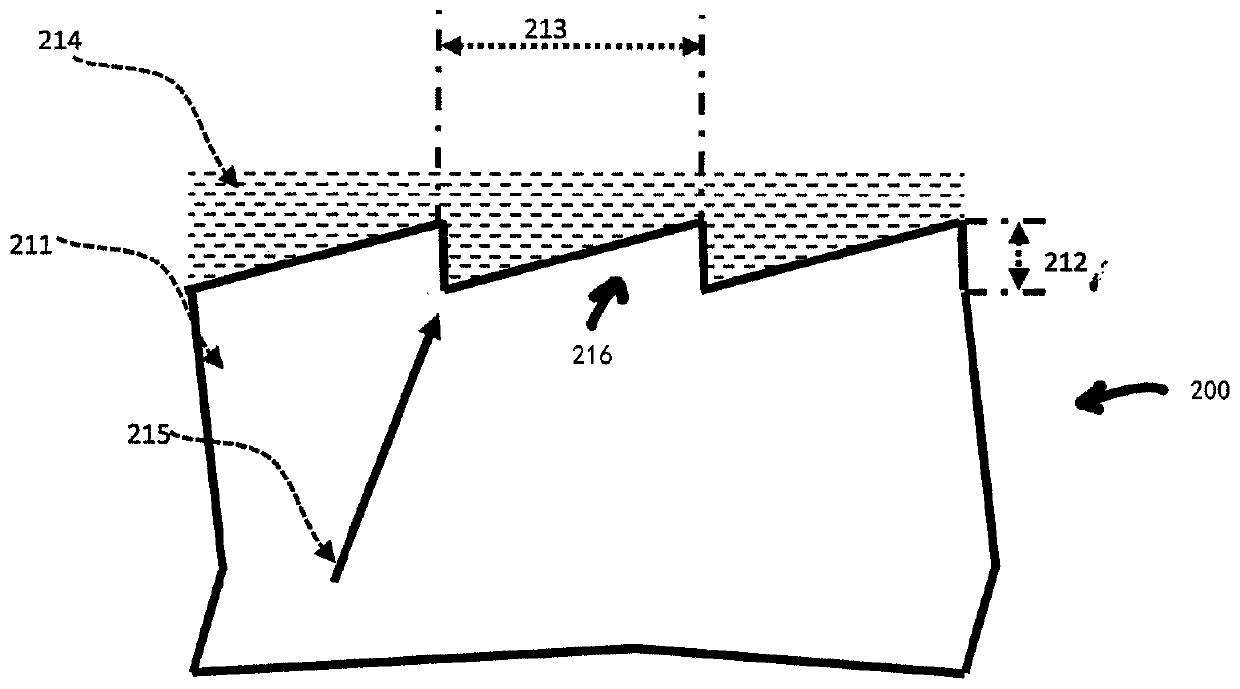

[0039] Figure 6 It is a cross-sectional view of the optical display device 600 in the embodiment of the present invention. The display device 600 includes an input diffractive optical element 618 mounted on a substrate 611 . The input diffractive optical element 618 comprises a blazed grating 619 with a period 613 of 520 nm and a feature height 612 of 220 nm. The input diffractive optical element 618 also includes a residual layer 617 formed from the same polymer-based material that forms the blazed grating 619 and produced simultaneously with the blazed grating 619 . Residual layer 617 is positioned adjacent to substrate 611 . The depth of the residual layer 617 is consistent across the blazed grating 619 . In this example, the residual layer depth is 80nm. On the surface of the blazed grating 619 a silver coating 614 is applied. The substrate 611 is generally made of glass and has a refractive index of 1.5. The refractive index of the input diffractive optical element...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com