A method for manufacturing a multi-step microlens and a method for manufacturing a step of an optical element

A production method and technology of optical components, applied in the direction of optical components, optics, lenses, etc., can solve problems such as alignment, photolithography, etching, etc., and achieve the effect of meeting high-precision requirements, reducing difficulty, and reducing process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

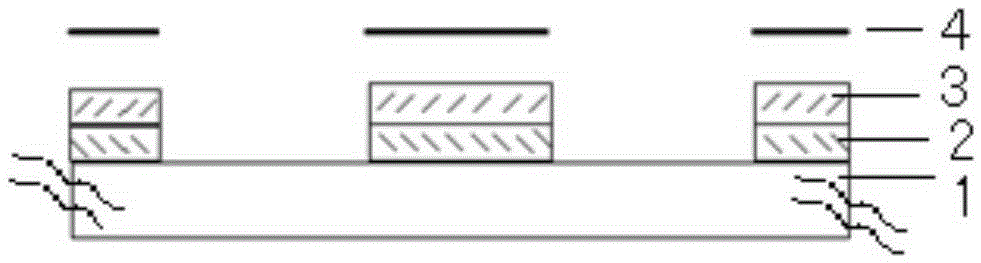

[0025] When using a multi-step microlens manufacturing method of the present invention to manufacture a quartz-based diffractive microlens array, the specific steps are as shown in the figure:

[0026] 1) Sputtering a Cr metal layer on the quartz substrate 1 with a magnetron sputtering table as the shielding layer 2;

[0027] 2) Spin-coat positive photoresist AZ1500 on the metal layer 2; use the mask plate 4 to expose, carry out photolithography development, and make a pattern as the etching mask layer 3; use Cr etching solution to etch out the outline as the innermost ring The shielding layer with the belt is used as a mask;

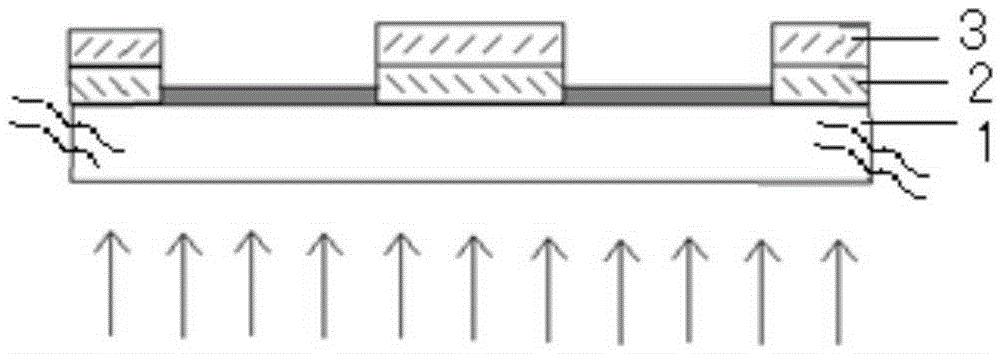

[0028] 3) spin-coating negative photoresist 5; exposing and developing on the back of the substrate 1, and the obtained negative photoresist 5 is used as an etching mask as a protective layer;

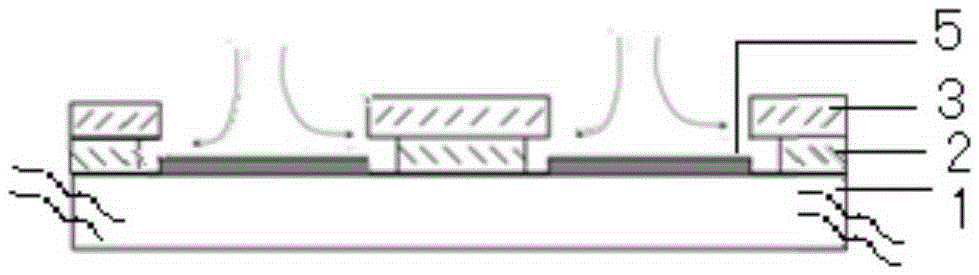

[0029] 4) Laterally corrode the shielding layer Cr metal layer 1 in 1), and the corrosion amount is the width of the second step;

[0030] 5) Remove the posit...

Embodiment 2

[0041] The invention also provides a method for manufacturing optical element steps, which is used for manufacturing optical elements with two layers of steps. Specific steps are as follows:

[0042] 1) Sputtering a Cr metal layer 2 on a quartz substrate 1 with a magnetron sputtering table as a shielding layer;

[0043] 2) Spin-coat positive photoresist AZ1500 on the metal layer 1; use the mask plate 4 to expose, carry out photolithography development, and make a pattern as the etching mask layer 3; use Cr etching solution to etch out the outline as the innermost ring The shielding layer with the belt is used as a mask;

[0044] 3) Spin-coating negative photoresist 5; exposing and developing on the back of the substrate, the obtained negative photoresist 5 is used as an etching mask as a protective layer;

[0045] 4) Laterally corrode the shielding layer Cr metal layer 2 in 1), and the corrosion amount is the width of the second step;

[0046] 5) Remove the positive photore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com