Fabrication method of high-precision multi-step microlens array

A technology of a microlens array and a manufacturing method, which is applied to the photoengraving process of lens and pattern surface, optics and other directions, can solve the problems of low yield and high requirements for production accuracy, and achieves high yield, low requirements for production accuracy and large size. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

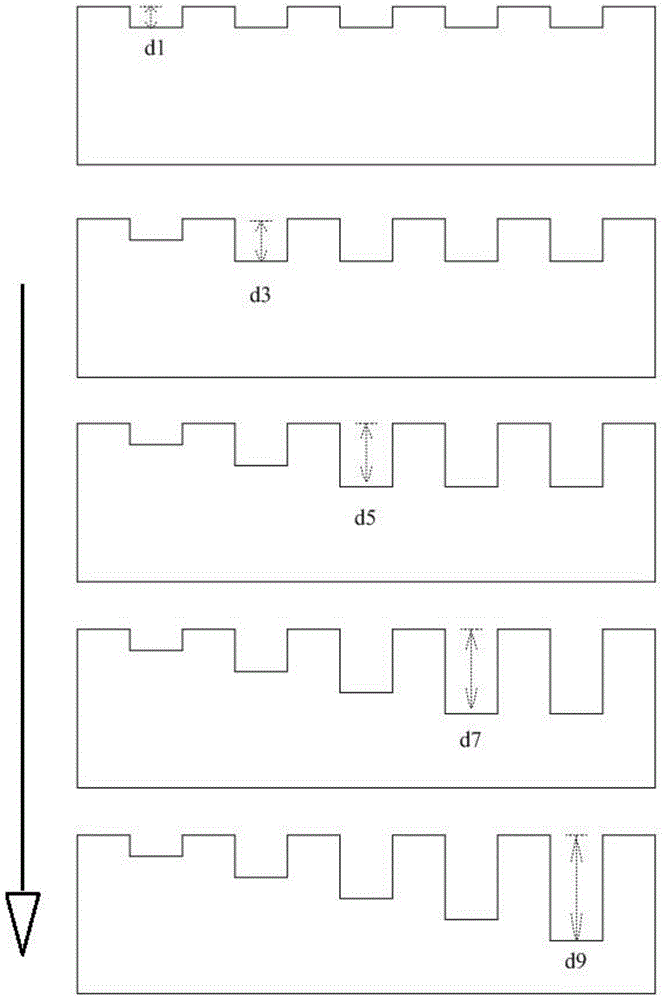

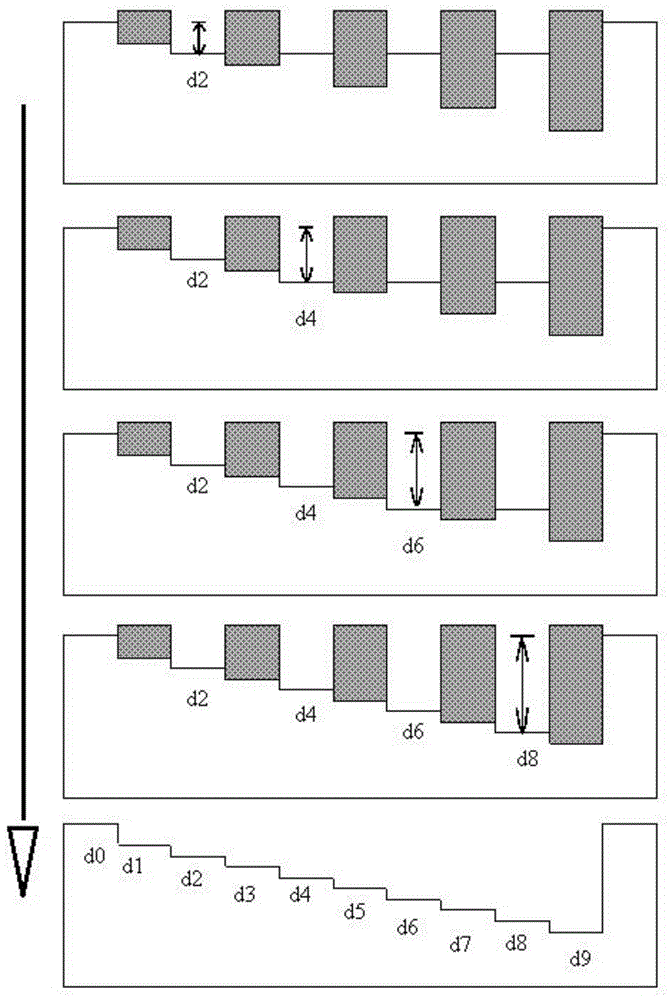

[0060] Figure 3 to Figure 5 It is a method for making four-step microlens arrays, and the depths of all the steps of the microlenses are d0, d1, d2, and d3; the specific steps are as follows:

[0061] 1), make the first set of steps set at intervals on the substrate, the steps are:

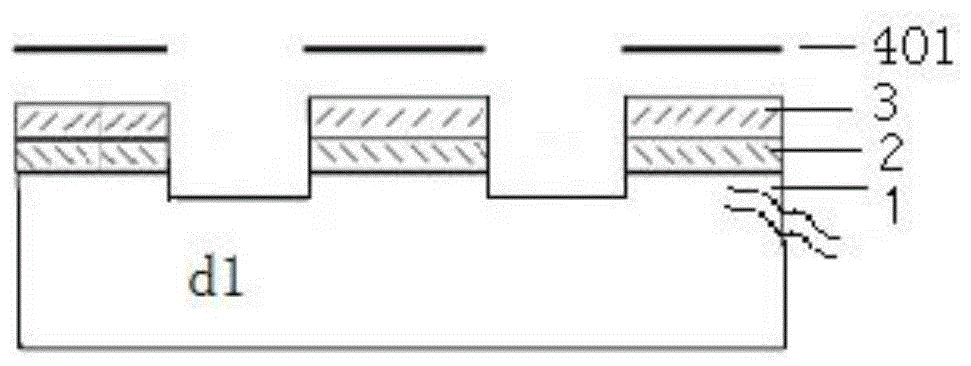

[0062] a), make a sacrificial layer and a positive photoresist layer on the substrate, perform photolithography and development by using a mask plate, and then etch two steps arranged at intervals and with a depth of d1; this step is as follows image 3 As shown, wherein the sacrificial layer is a negative photoresist layer, and the substrate can be a quartz material that is transparent to ultraviolet light, or a material such as silicon or germanium that is not transparent to ultraviolet light;

[0063] b), re-spin the positive photoresist, use the corresponding mask for photolithography and development, protect the step d1 that reaches the set depth, and further etch the remaining steps to for...

Embodiment 3

[0067] The difference from Example 2 is that, before etching the second set of steps, a mask protection layer is made by using the method of back exposure, such as Figure 8 Shown:

[0068] 1), make the first set of steps set at intervals on the substrate, the steps are:

[0069] a) Make a sacrificial layer and a positive photoresist layer on the substrate, and use a mask plate for photolithography, development and etching to etch two steps at intervals with a depth of d1; where the shielding layer 6 is the sacrificial The layer is an opaque chromium metal layer, and the base is quartz that can transmit ultraviolet light;

[0070] b), re-spin the positive photoresist, use the corresponding mask for photolithography, development and corrosion, protect the step with a set depth of d1, and further etch the remaining steps to form a step with a depth of d3 ;

[0071] 2), make a second set of steps between the first set of steps; the steps are:

[0072] c), apply negative photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com