Mulberry leaf beverage granules and preparation method thereof

A production method and technology of mulberry leaves, which are applied in the field of mulberry leaf beverage granules and its production, can solve problems such as inconvenience, and achieve the effects of improving taste, enhancing nutritional value, and improving absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

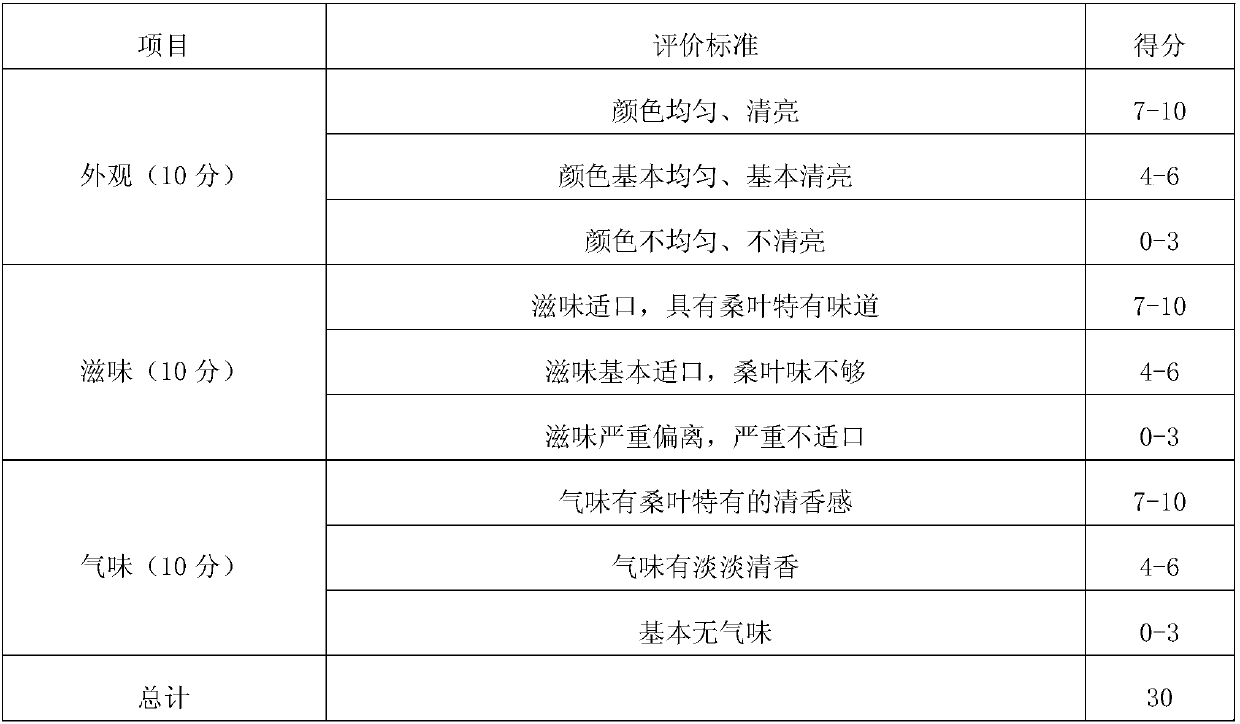

Examples

Embodiment 1

[0021] A mulberry leaf beverage granule, which is made of the following raw materials in parts by weight: 180 parts of mulberry leaves, 15 parts of licorice, 12 parts of red peony, 10 parts of lily, 4 parts of cortex mulberry, and 5 parts of Radix Ophiopogon japonicus , 4 parts of rehmannia glutinosa, 12 parts of glucose, 8-parts of maltodextrin, and appropriate amount of water.

[0022] The preparation method of mulberry leaf beverage granules comprises the following steps:

[0023] (1) After cleaning the mulberry leaves, put them in a sterile room to dry, and crush the dried mulberry leaves to a particle size of 2mm, and use supercritical CO 2 Extraction method, put the pulverized mulberry leaves into the extraction tank, add ethanol, at a temperature of 36°C, a pressure of 24MPa, CO 2 Extract for 60min under the condition of volume flow rate of 120ml / min, then separate the CO in the filtrate 2 and ethanol to obtain the mulberry leaf extract; wherein, the volume concentrat...

Embodiment 2

[0028] A mulberry leaf beverage granule, which is made of the following raw materials in parts by weight: 200 parts of mulberry leaves, 20 parts of licorice, 16 parts of red peony, 12 parts of lily, 6 parts of mulberry bark, and 8 parts of Radix Ophiopogon japonicus , 8 parts of raw rehmannia, 15 parts of glucose, 10 parts of maltodextrin, and appropriate amount of water.

[0029] The preparation method of mulberry leaf beverage granules comprises the following steps:

[0030] (1) After cleaning the mulberry leaves, put them in a sterile room to dry, and crush the dried mulberry leaves to a particle size of 3mm, and use supercritical CO 2 Extraction method, put the pulverized mulberry leaves into the extraction tank, add ethanol, at a temperature of 40°C, a pressure of 26MPa, CO 2 Extract for 80min under the condition of volume flow rate of 150ml / min, then separate the CO in the filtrate 2and ethanol to obtain the mulberry leaf extract; wherein, the volume concentration of t...

Embodiment 3

[0035] A mulberry leaf beverage granule, the mulberry leaf beverage granule is made of the following raw materials in parts by weight: 190 parts of mulberry leaves, 16 parts of licorice, 14 parts of red peony, 11 parts of lily, 5 parts of mulberry bark, and 6 parts of Ophiopogon japonicus , 6 parts of rehmannia glutinosa, 13 parts of glucose, 9 parts of maltodextrin, and appropriate amount of water.

[0036] The preparation method of mulberry leaf beverage granules comprises the following steps:

[0037] (1) After cleaning the mulberry leaves, put them in a sterile room to dry, and crush the dried mulberry leaves to a particle size of 2.5mm, and use supercritical CO 2 Extraction method, put the pulverized mulberry leaves into the extraction tank, add ethanol, at a temperature of 38°C, a pressure of 25MPa, CO 2 Extract for 70min under the condition of volume flow rate of 140ml / min, then separate the CO in the filtrate 2 and ethanol to obtain the mulberry leaf extract; wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com