A method for reducing purine content of whole soybean

A soybean and purine technology, which is applied in the field of reducing the purine content of whole soybeans, can solve the problems of soybean cell wall damage and inability to maintain soybean integrity, and achieves the effects of being widely used, beneficial to industrial production and improving the quality of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

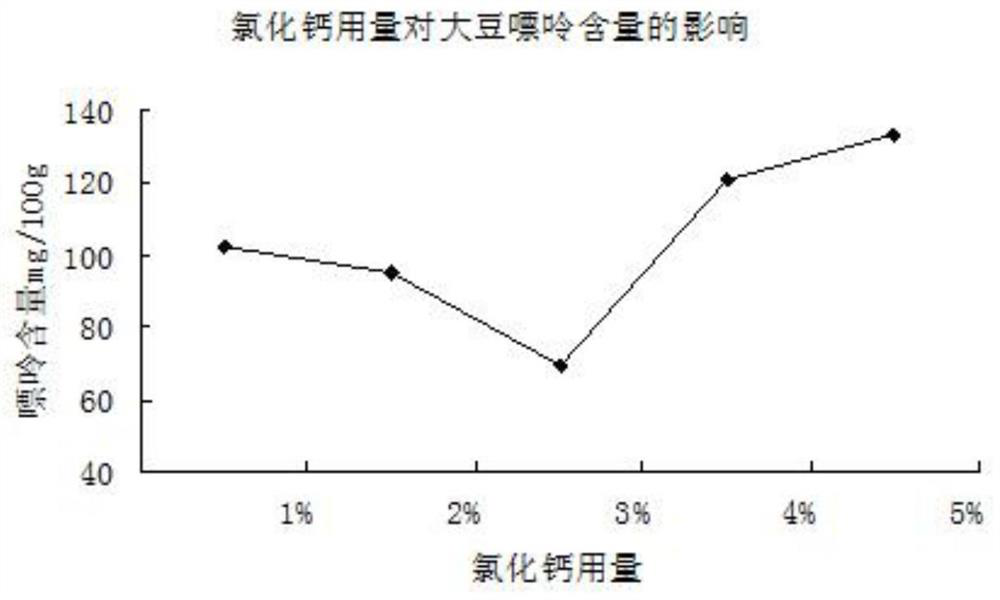

[0029] Select Zhonghuang No. 13 with a protein content of 39.46%, a fat content of 18.21%, and a purine content of 164.51mg / 100g as raw soybeans, and put appropriate amounts of soybeans in containers with concentrations of 1%, 2%, 3%, 4%, and 5% respectively. % calcium chloride aqueous solution in the beaker, add the rotor, put the beaker in the magnetic stirring water bath, stir and soak the soybeans. Wherein the soaking temperature is 60° C., and the soaking time is 3 hours. Thoroughly remove the calcium chloride on the surface of the soaked soybeans with clean water, put them into a high-voltage electric field pulse generator, and treat them with a pulse electric field strength of 15kv / cm, a pulse number of 15 times, and a pulse width of 2μs, and measure the purine content after cleaning. The result is as figure 1 Shown, when calcium chloride concentration is 3%, obtain protein content and be 34.22%, fat content 13.72%, the soybean product of purine content 69.23mg / 100g, p...

Embodiment 2

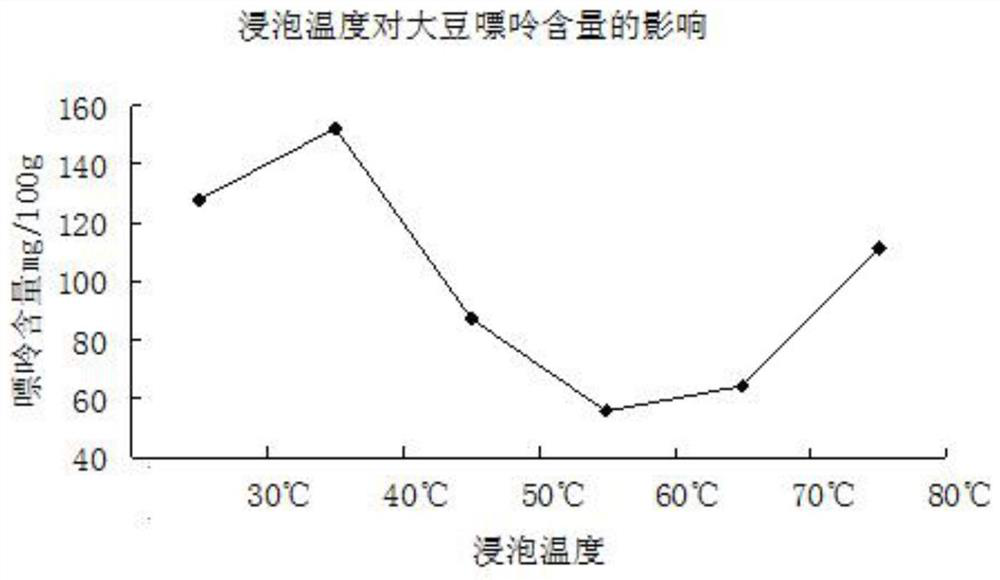

[0031] Select the Zhonghuang No. 13 with protein content of 39.46%, fat content of 18.21%, and purine content of 164.51mg / 100g as the raw soybean, put an appropriate amount of soybean in the beaker with 3% calcium chloride aqueous solution, add the rotor, Place the beaker in a magnetic stirring water bath to stir and soak the soybeans. The soaking temperatures are 30°C, 40°C, 50°C, 60°C, 70°C and 80°C respectively, and the soaking time is 3 hours. Thoroughly remove the calcium chloride on the surface of the soaked soybeans with clean water, put them into a high-voltage electric field pulse generator, and treat them with a pulse electric field strength of 25kv / cm, a pulse number of 20 times, and a pulse width of 6μs, and measure the purine content after cleaning. The result is as figure 2 As shown, when the soaking temperature was 60°C, the protein content was 30.37%, the fat content was 10.25%, and the soybean product with a purine content of 55.89mg / 100g was obtained, and t...

Embodiment 3

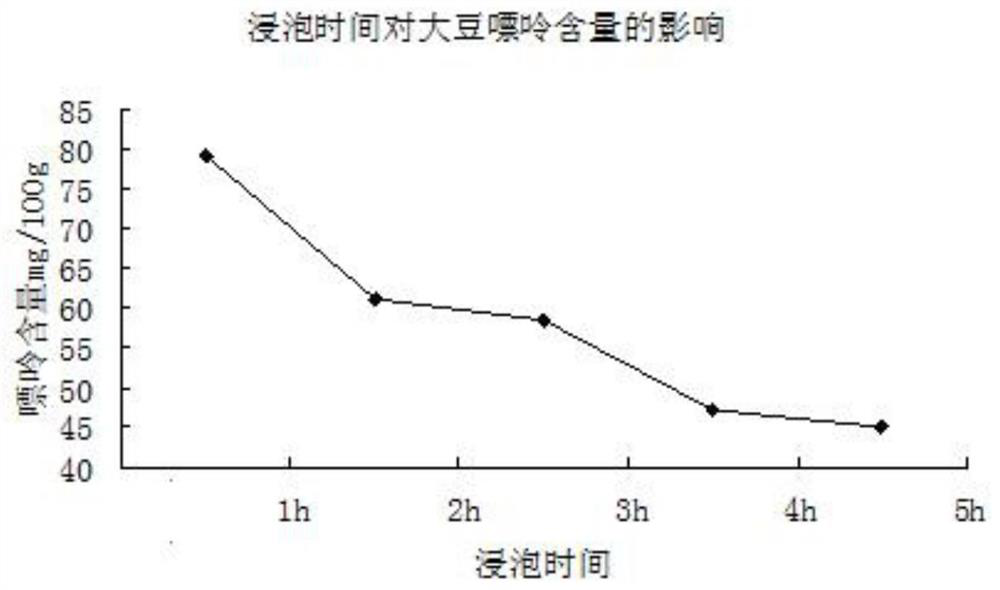

[0033] Select the Zhonghuang No. 13 with protein content of 39.46%, fat content of 18.21%, and purine content of 164.51mg / 100g as the raw soybean, put an appropriate amount of soybean in the beaker with 3% calcium chloride aqueous solution, add the rotor, Place the beaker in a magnetic stirring water bath to stir and soak the soybeans. The soaking temperature is 60°C, and the soaking time is 1h, 2h, 3h, 4h and 5h, respectively. Thoroughly remove the calcium chloride on the surface of the soaked soybeans with clean water, put them into a high-voltage electric field pulse generator, and treat them with a pulse electric field strength of 15kv / cm, a pulse number of 20 times, and a pulse width of 4μs, and measure the purine content after cleaning. The result is as image 3 As shown, when soaking time is 3h, obtain protein content and be 31.24%, fat content 13.65%, the soybean product of purine content 58.36mg / 100g, purine removal rate reaches 64.5%, when soaking time is 1h, its pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com