Intelligent cooker

An intelligent cooking and rack technology, applied in cooking utensils, household appliances, applications, etc., can solve the problems of insufficient height, increase the size of equipment space, increase labor input, etc., achieve accurate positioning, improve operational safety, reduce The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

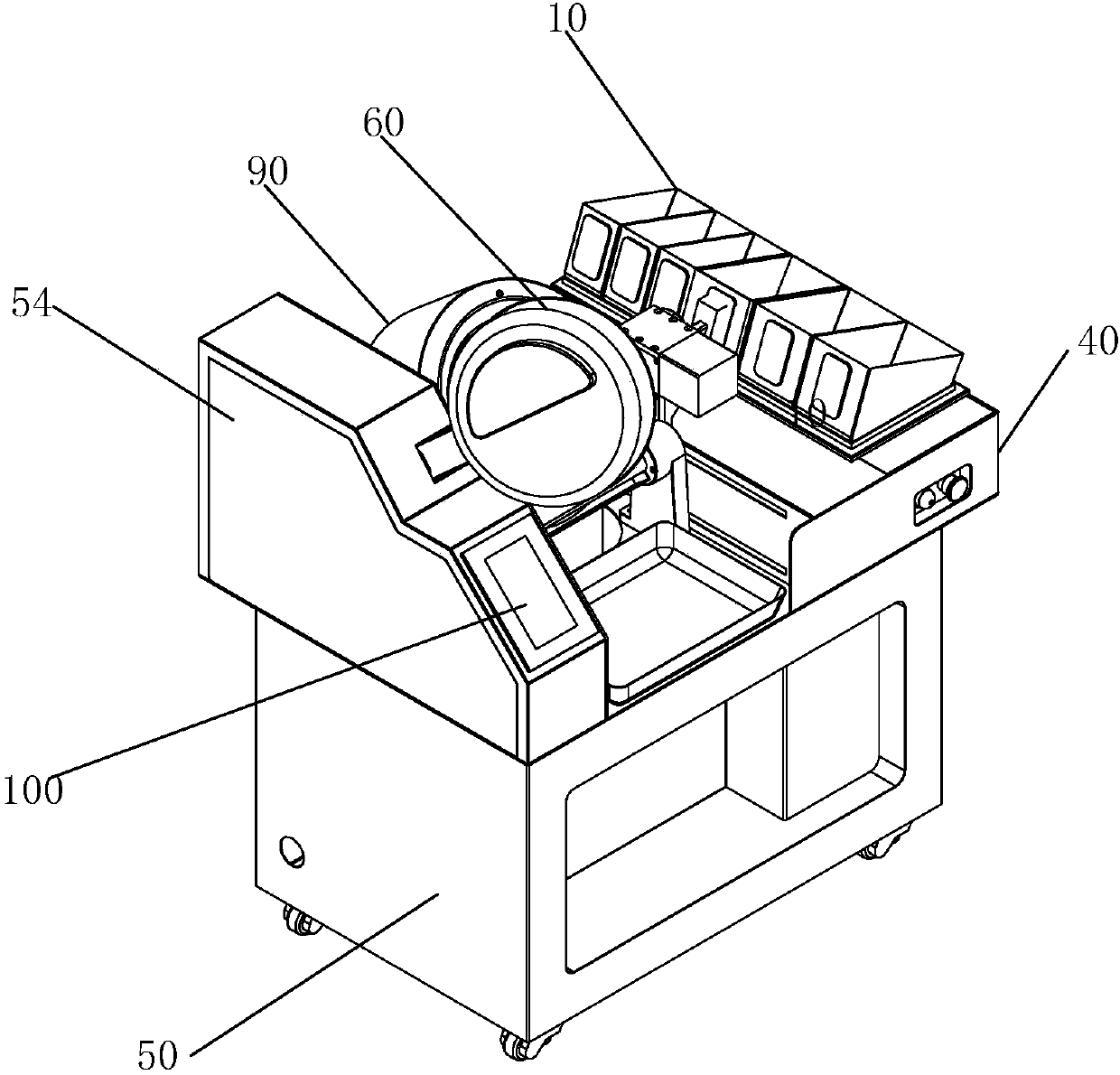

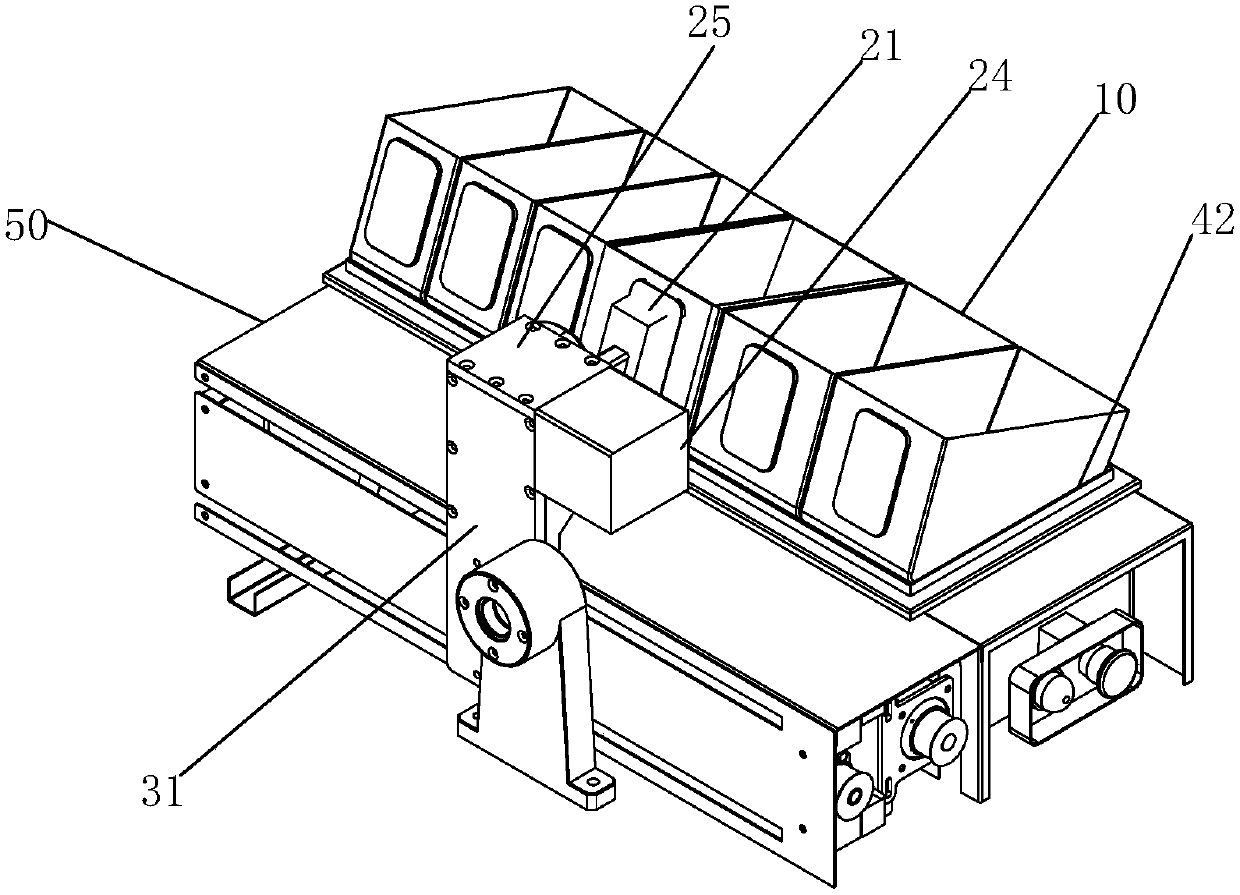

[0059] refer to Figure 1 to Figure 15 , an intelligent cooking machine, including a frame and a pot body assembly 90 located on the frame, a pot cover assembly, a main material feeding assembly, a PLC control device 100, and the like. The main material feeding assembly includes several main material boxes 10, a material lifting structure, a weighing structure 43 and a loading platform 40 and the like. The loading table 40 is located on one side of the frame 50 and has a loading surface 41 and a groove 42 . The loading surface 41 is located at the bottom of the groove 42 and is inclined at a certain angle with the horizontal plane. The angle is an acute angle. The groove 42 has a triangular or other polygonal cross section. The plurality of main magazines 10 are placed on the loading surface 41, and are partially limited in the groove 42 and arranged in sequence. Since the loading surface 41 is inclined, the main magazine 10 is also in an inclined state.

[0060] The weighi...

Embodiment 2

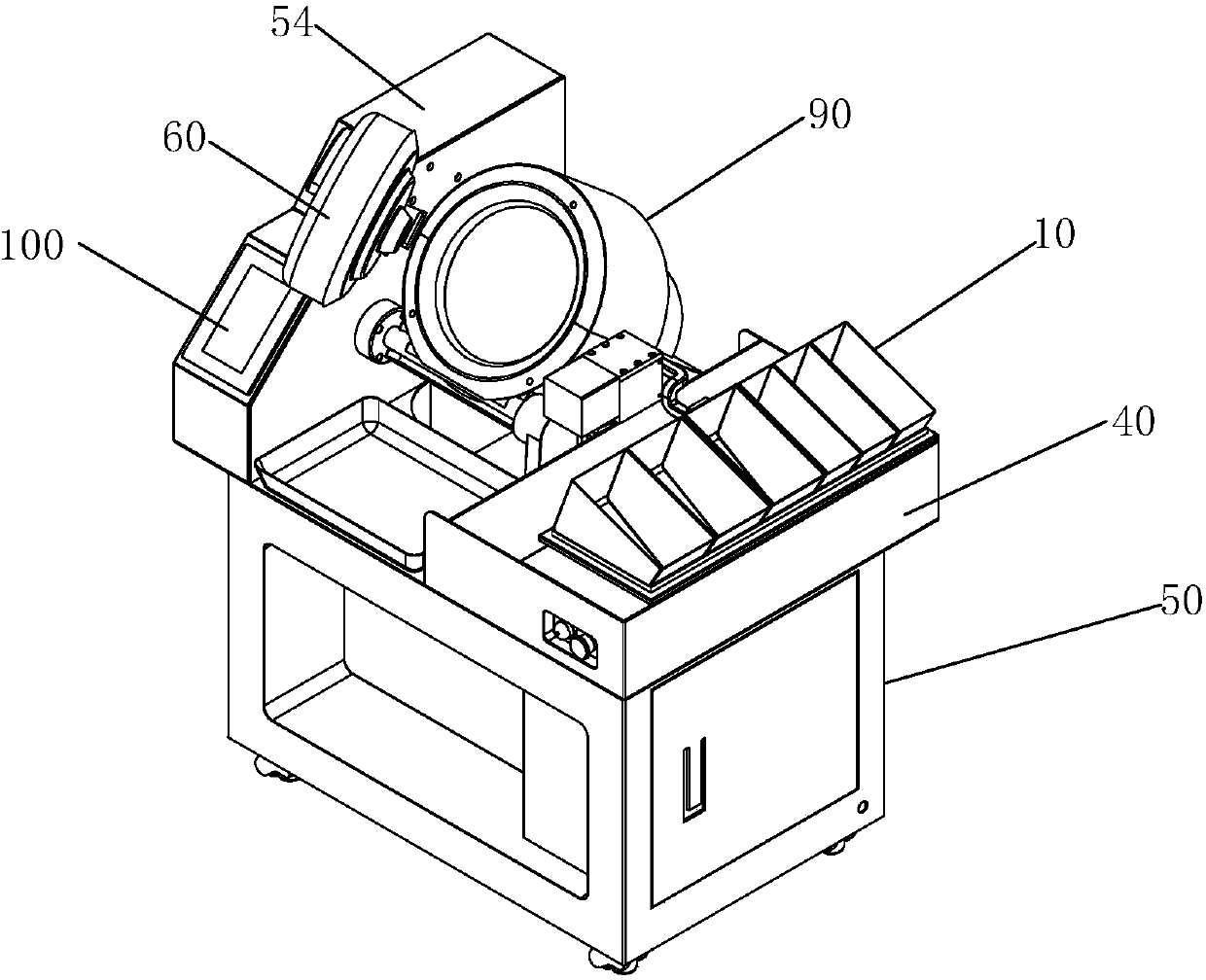

[0087] An intelligent cooking machine, its main technical features are the same as those in Embodiment 1, the difference is: refer to Figure 16 - Figure 19 , the loading platform 40 is located on one side of the frame 50 and is provided with a loading surface 41, and the loading surface 41 is arranged horizontally.

[0088] Main magazine 10 is provided with connector, and this connector comprises fixed plate 12, sheet metal 11, fulcrum 13 and some elastic parts 14, and this fixed plate 12 is fixed on the side wall of main material box 10; This fulcrum 13 one ends and The fixed plate 12 is fixedly connected, and the other end is rotatably connected to the metal sheet 11 ; one end of the elastic member 14 is fixed on the metal sheet 11 , and the other end is opposite to or connected to the fixed plate 12 . The metal sheet 11 can be an iron sheet or other metal sheets that can be absorbed by the electromagnet. The elastic member 14 adopts a spring, and its number can be two, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com