Long-acting controlled release composite film with gel-state pressure transmission control layer and preparation method of long-acting controlled release composite film

A technology of transmission control layer and pressure control, applied in the field of medical composite membrane, can solve problems such as difficulty in controlled release of drug-loaded composite membrane, and achieve the effect of simplifying process steps and improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

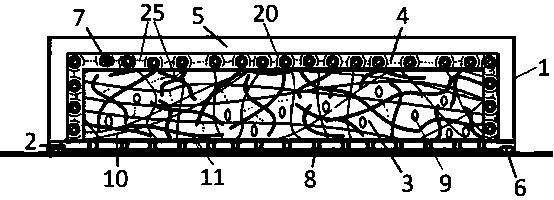

[0028] Such as figure 1 , 2 As shown, a long-acting controlled-release composite membrane with a gel-state pressure transmission control layer includes a controlled-release composite carrier 1 and a microchannel transmission layer 2 arranged at the bottom of the controlled-release composite carrier 1. The composite membrane main body 1 is from the inside to the The outer layer is divided into the interpenetrating network micro-stent structure layer 3, the swellable microgel pressure transmission control layer 4 and the restrictive pressure transmission control layer 5, and the inside of the swellable microgel pressure transmission control layer 4 Uniformly distributed swellable pressure-controlling microgel 7 and microgel reinforcing agent 20 for strengthening, the interpenetrating mesh micro-stent structure layer 3 is composed of interwoven first mesh-through polymer chains 10, second mesh-through polymer chains Composed of polymer chains 11 and functional bodies 9, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com