A kind of microporous array filter membrane and its preparation method and application

A technology of microwell array and microcolumn array, applied in biochemical equipment and methods, methods of supporting/immobilizing microorganisms, methods of sterilization, etc., can solve problems such as low recovery purity and influence on cell activity, and achieve increased volume Effects of throughput, reduced non-specific adhesion, and high recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

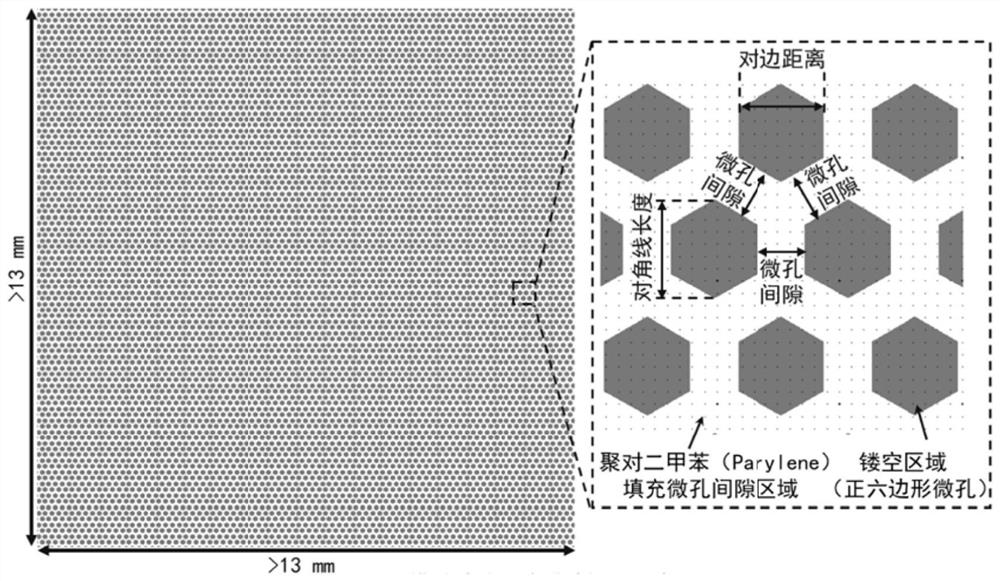

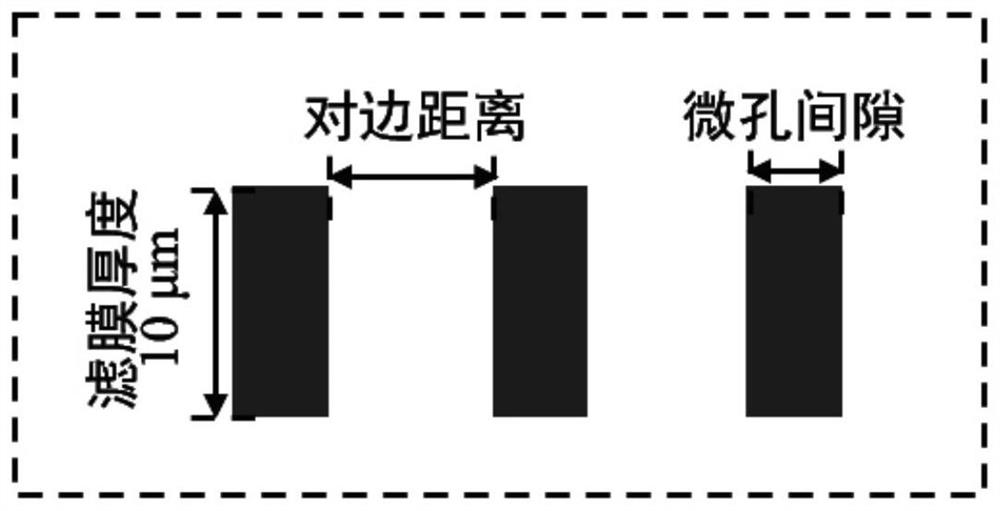

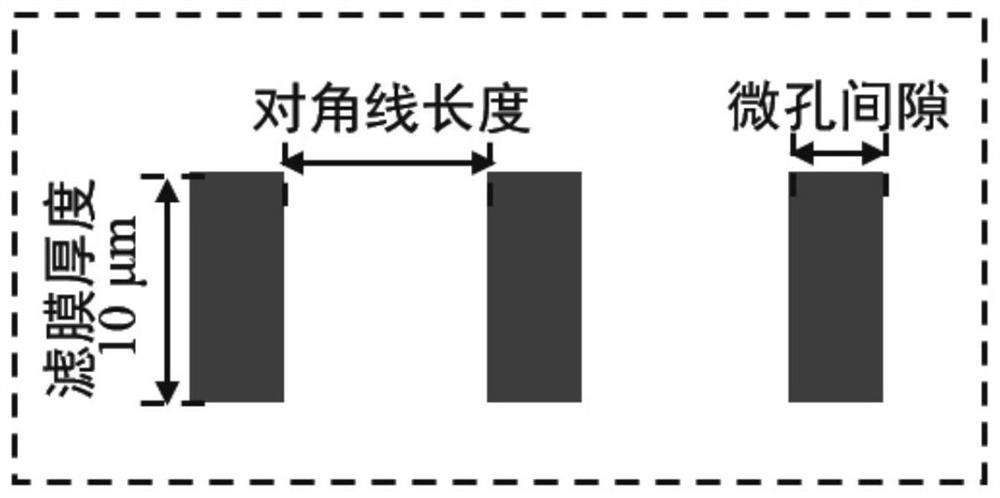

[0042] The design of the microporous array filter membrane with regular hexagonal microporous shape of the present invention is shown in Figure 1 (a)-(c), wherein the interstices of the micropores are filled and connected by parylene, and are maintained to form a filter membrane, regular hexagonal Micropores are hollowed-out areas on the filter membrane. The main features of the microporous array filter membrane are as follows:

[0043] (1) It has 2.5-dimensional geometric characteristics;

[0044] (2) It has a large effective filtration area (≥13mm×13mm), and can achieve ultra-large volume flux (≥150mL / min);

[0045] (3) With precise pore size / micropore gap, high-performance cell filtration can be achieved;

[0046] (4) The shape of the micropores is a regular hexagon, so as to ensure that the gap width of adjacent micropores is consistent throughout the filter membrane, and the diameter difference between the circumscribed circle and the inscribed circle of the micropores ...

experiment example 1

[0057] Experimental Example 1: Membrane Performance Test and Simulation

[0058] 1—force sensor, 2—microporous array filter, 3—PMMA carrier, 4—gold reflective coating on the surface, 5—chromatic aberration lens, 6—beam splitter, 7—pinhole, 8—spectrometer; this experiment uses CCI The non-contact optical method was used to test the mechanical properties of the filter membrane. The test principle is shown in Figure 5(a), which mainly includes three parts: mechanical loading, optical imaging and signal processing: the mechanical loading part exerts force on the microporous array filter membrane 2 through the mechanical sensor 1, and under the action of the external force, the filter membrane When deformation occurs, the position of the lower surface of the filter membrane changes in the vertical direction (that is, longitudinal deformation occurs), which is detected by the optical imaging system, and the corresponding image information is converted into an optical imaging signal ...

experiment example 2

[0069] Experimental example 2: Rigid microsphere perforation test of membrane filtration performance

[0070] Four microporous array filter membranes are assembled into a multi-stage filtration system from top to bottom according to the order of pore size from large to small, and the 10μm film thickness parylene regular hexagonal microporous array used The filter membrane pore size / gap (the size actually measured according to the electron microscope photo after processing) is as follows: 14.52±0.20μm / 4.43±0.06μm, 11.21±0.11μm / 4.77±0.15μm, 9.13±0.09μm / 4.69±0.24μm , 7.51±0.13μm / 4.46±0.09μm. 10 mL of deionized water suspended with polystyrene microspheres (6-1-2200, Tianjin Beisile Chromatography Technology Development Center) with a diameter range of 6-22 μm was filtered through the assembled multilayer filtration system. After filtration, remove the parylene filter membrane and place it overnight at room temperature, spray gold on the surface of the filter membrane with captu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com