Drill bit cleaning system

A cleaning system and drill bit technology, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of affecting cleaning effect, affecting cleaning efficiency, and high cleaning cost, so as to improve cleaning efficiency. , The effect of ensuring cleaning effect and reducing cleaning cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

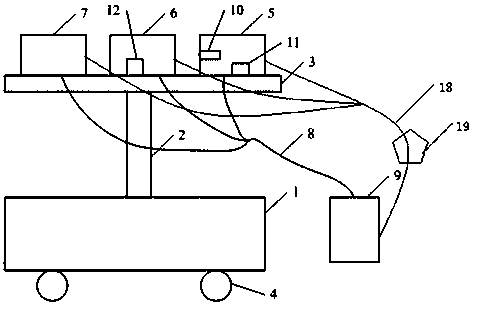

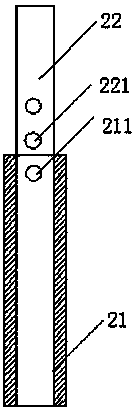

[0024] The drill bit cleaning system of this embodiment, such as figure 1 As shown, it includes a base 1, a rotating shaft 2, and a disc 3. The base 1 is provided with brake casters 4, and the bottom of the disc 3 is provided with a circular groove, such as figure 2 As shown, the rotating shaft 2 includes a fixed shaft 21 and a telescopic shaft 22, and a pair of pin holes 211 are provided at the upper end of the fixed shaft 21, and several pairs of positioning holes 221 are provided at the lower end of the telescopic shaft 22, which are inserted into the In pin hole 211 and positioning hole 221, fixed shaft 21 and telescopic shaft 22 are fixed;

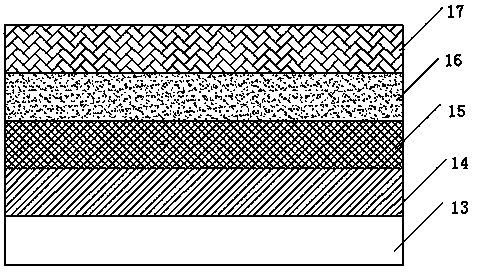

[0025] The upper surface of the disk 3 is provided with a first cleaning box 5, a second cleaning box 6 and a third cleaning box 7, and the upper surfaces of the first cleaning box 5, the second cleaning box 6 and the third cleaning box 7 are all open, The bottom surfaces of the first cleaning case 5, the second cleaning case 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com