Mold modification mechanism for modifying bending deformation of punch products

A bending deformation and vertical bending deformation technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of stamping forming, low production cost, bending deformation of metal lead frames, etc., to avoid the cumbersome maintenance and adjustment. Action, improve the production qualification rate, and facilitate the adjustment of the work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The application will be further described in detail below through specific implementations in conjunction with the drawings.

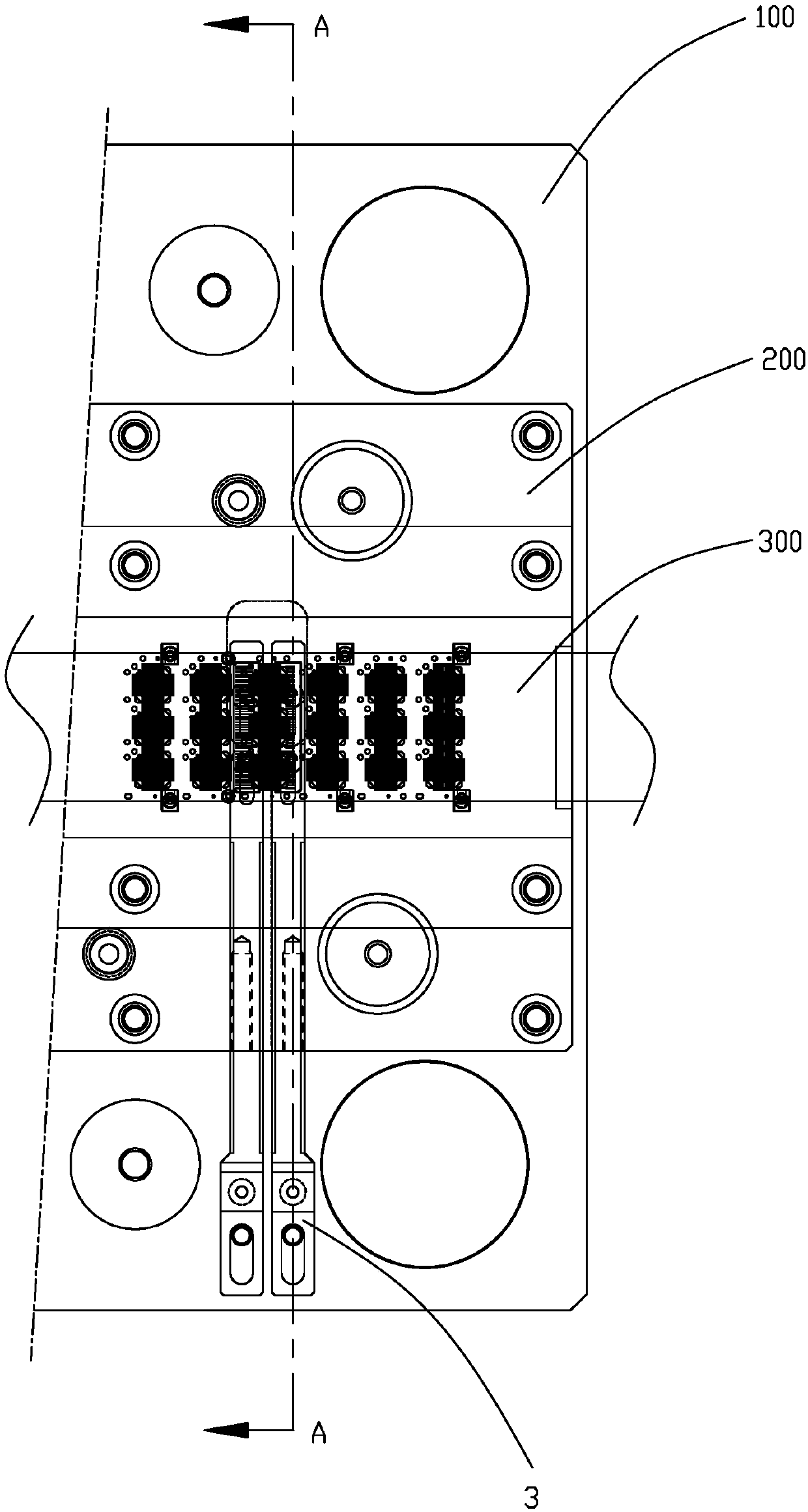

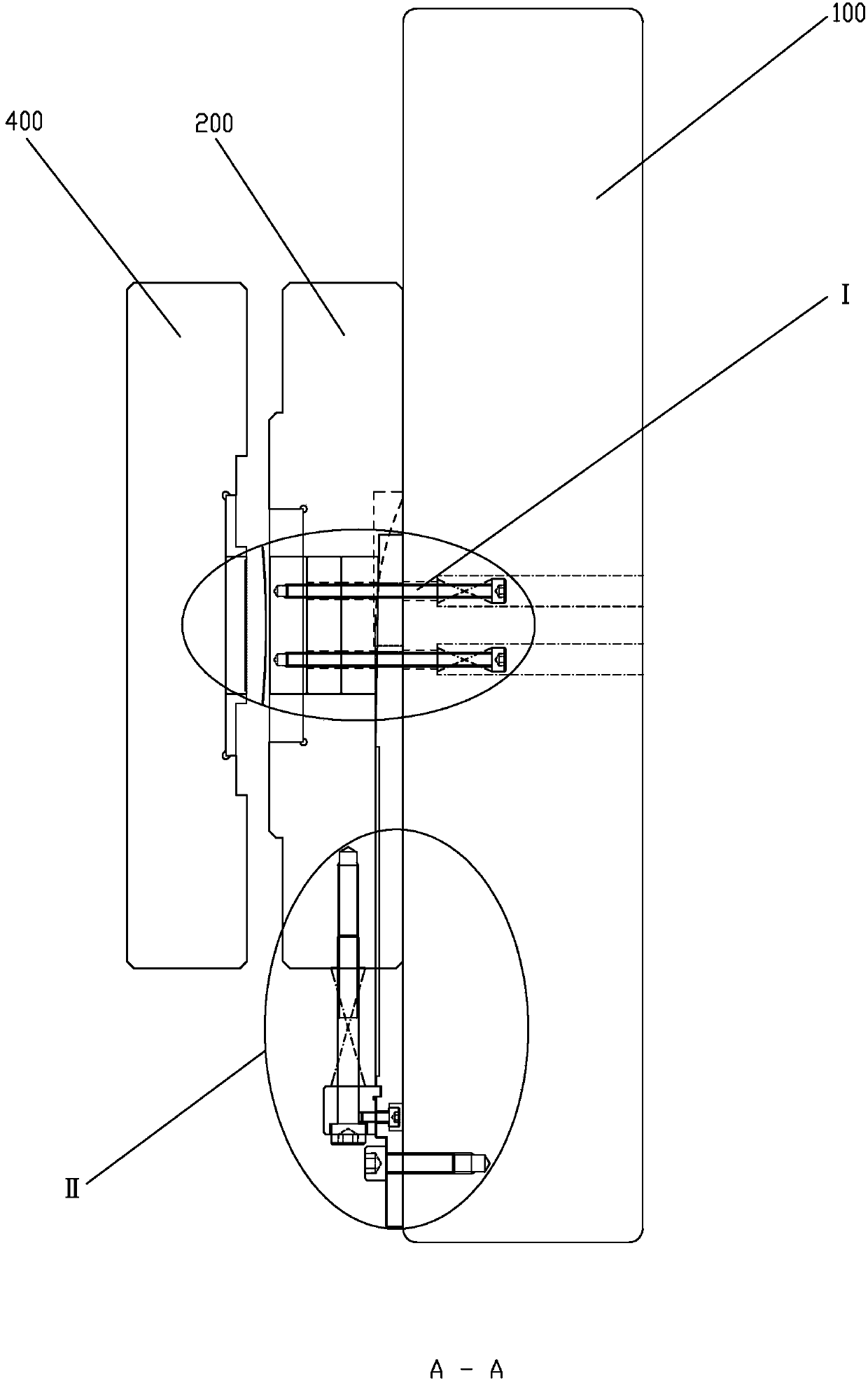

[0042] Such as Figure 1-12 As shown, the mold correction mechanism for correcting the bending deformation of the stamping product includes a stripping correction insert 1, a lower mold correction insert 2 and a movement adjustment assembly 3.

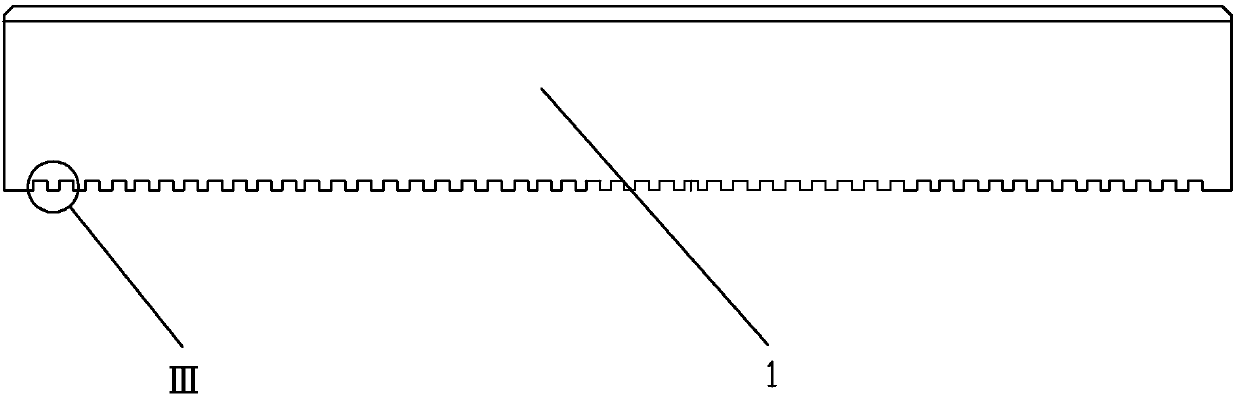

[0043] Specifically, the stripping correction insert 1 is arranged on the stripping back plate 400, above the product strip 300 that has vertical bending deformation and moves forward in the transverse direction of the stripping back plate 400, and is provided on its lower side There are a plurality of modified tooth grooves 11 which are concave and are arranged at intervals along the longitudinal direction. The lower mold correcting insert 2 is arranged on the lower mold back plate 200, located below the stripping correcting insert 1, and on its upper side is provided with the correcting tooth groove 11 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com