Plastic packaging mould and plastic packaging method

A plastic sealing mold and plastic sealing technology, applied in the direction of coating, etc., can solve the problems of semiconductor package thickness, single length and width, single initial depth of injection groove, etc., to improve production efficiency and production efficiency, and improve machine utilization , Improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

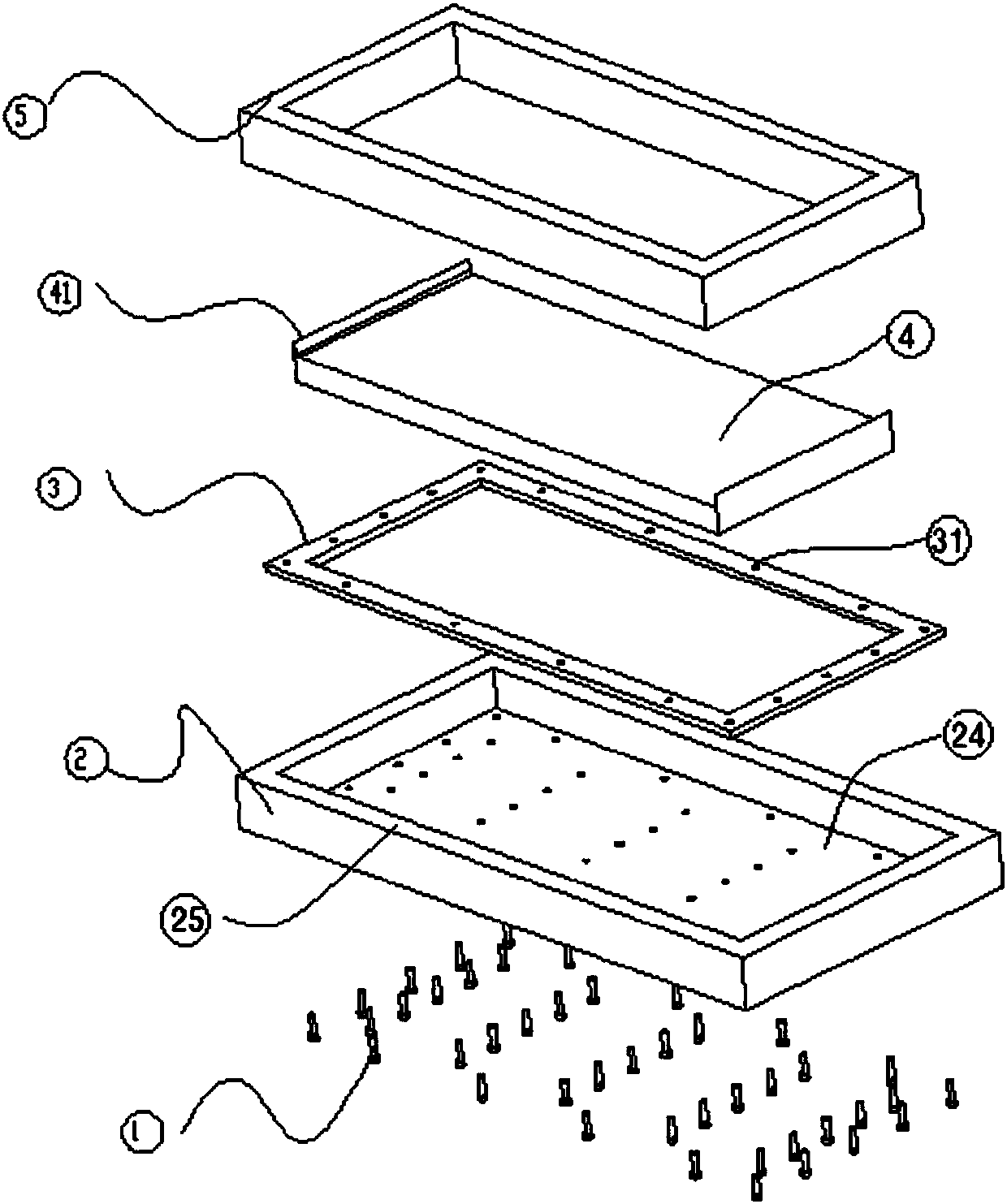

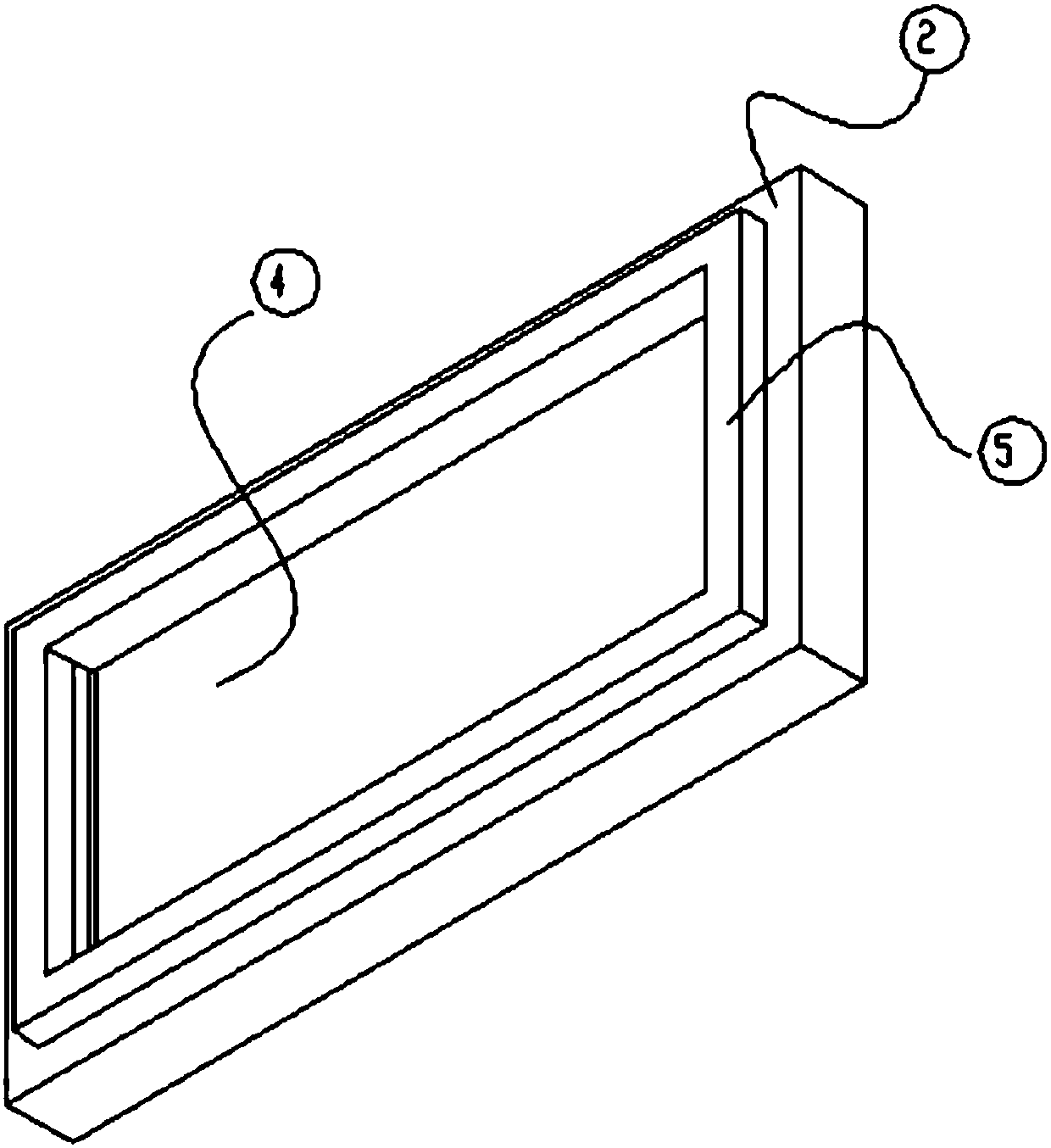

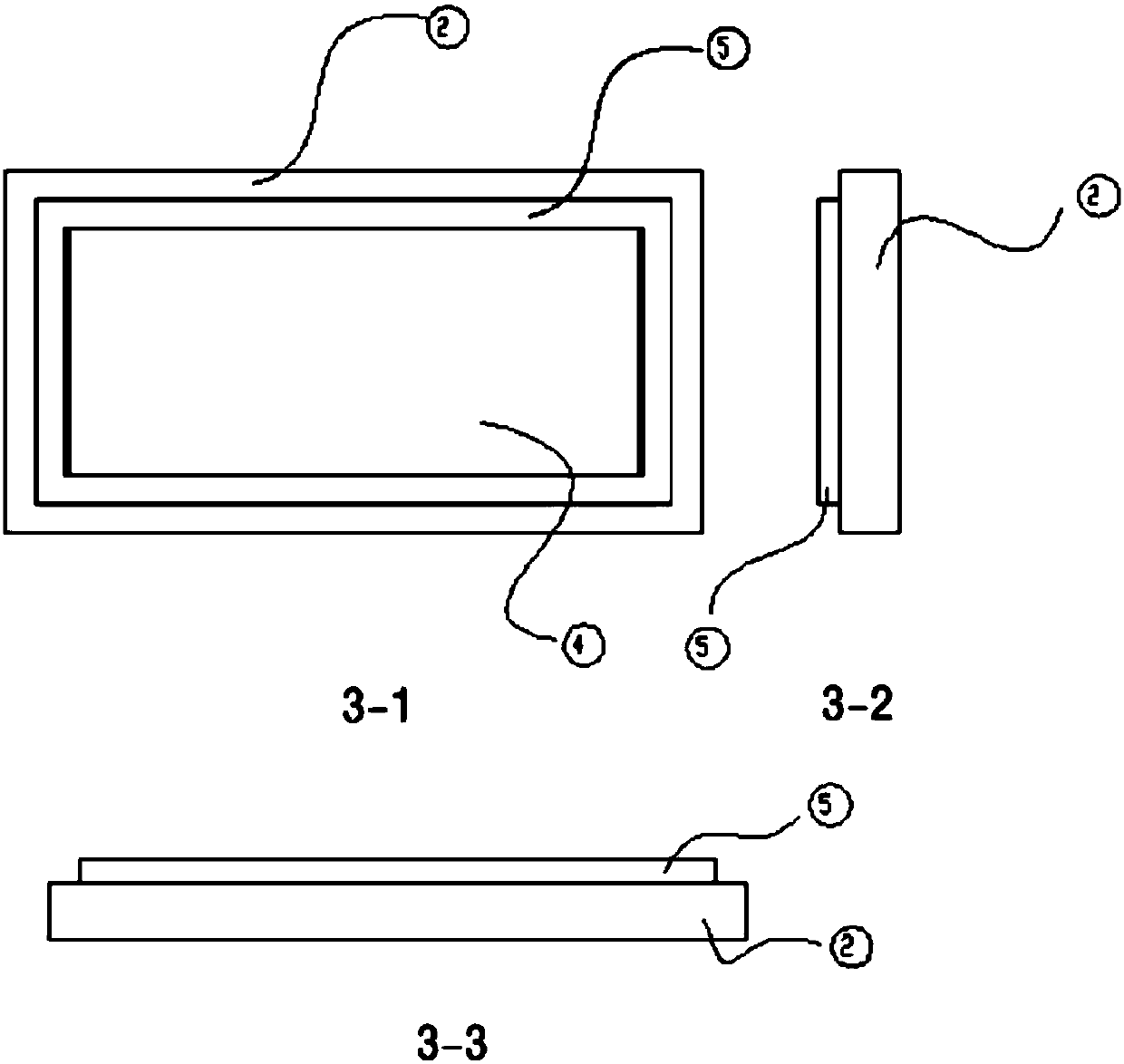

[0081] Such as Figure 1-10 As shown, a plastic sealing mold includes: a base 2, the base 2 has an accommodating cavity 24; a cavity frame group, the cavity frame group includes several mutually replaceable cavity frames 5, and several mutually replaceable At least two of the cavity frames 5 have different sizes; each cavity frame 5 can be accommodated in the accommodating cavity 24, and is detachably connected to the base 2; and, the insert 4, The insert 4 is accommodated in the cavity frame 5 and adapted to the inner wall of the cavity frame 5 , so that the surface of the insert 4 near the accommodating cavity 24 and the inner wall of the cavity frame 5 form a plastic-encapsulated cavity.

[0082] It is worth pointing out that the different dimensions of the cavity frame 5 in this embodiment means that the internal accommodation space is different (so as to produce plastic products with different plastic sealing requirements). In practical applications, since this cavity fra...

Embodiment 2

[0084] Such as Figure 1-10 As shown, on the basis of the above-mentioned embodiment, at least two cavity frames 5 have different sizes along the frame depth direction among several interchangeable cavity frames 5; each cavity frame 5 can be accommodated in It is accommodated in the cavity 24 and is detachably connected with the base 2; and, the insert 4 is accommodated in the cavity frame 5 and is adapted to the inner wall of the cavity frame 5, so that the insert 4 is close to the set The surface on the side of the outer surface 25 of the accommodating cavity 24 and the inner wall of the cavity frame 5 form a plastic-encapsulated cavity. The manufacturer can process the product to be plastic-sealed (or the product to be plastic-sealed) by replacing the cavity frame 5 with different frame depths according to the film thickness of the plastic-sealed product, which greatly simplifies the operation process and complexity of mold replacement.

Embodiment 3

[0086] Such as Figure 1-10 As shown, on the basis of the above-mentioned embodiment, at least one cavity frame 5 includes several (at least two) sub-cavity frames, and each sub-cavity frame is provided with a sub-insert 4 adapted to it; so that The surface of the sub-insert 4 near the outer surface 25 and the inner wall of the sub-cavity frame form a sub-molding cavity. Like this, at least two kinds of cavity frames 5 are included in the cavity frame group. The cavity frame 5 of the sub-cavity frame, the second type of cavity frame 5 only contains one sub-cavity frame, and the film thickness of the above two cavity frames 5 is different, while the frame depth of the same type of cavity frame 5 If they are the same, the plastic sealing mold can process two kinds of plastic sealing products with different film thicknesses and different sizes; when there are only two kinds of cavity frames 5 in the cavity frame group, the first type of cavity frame 5 (including at least one cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com