A zn-mof material with cationic sensing properties and its preparation method

A cation and sensing technology, applied in luminescent materials, analytical materials, material excitation analysis, etc., can solve problems that have not been seen in literature reports, and achieve good cation sensing performance, excellent application prospects, and mild conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

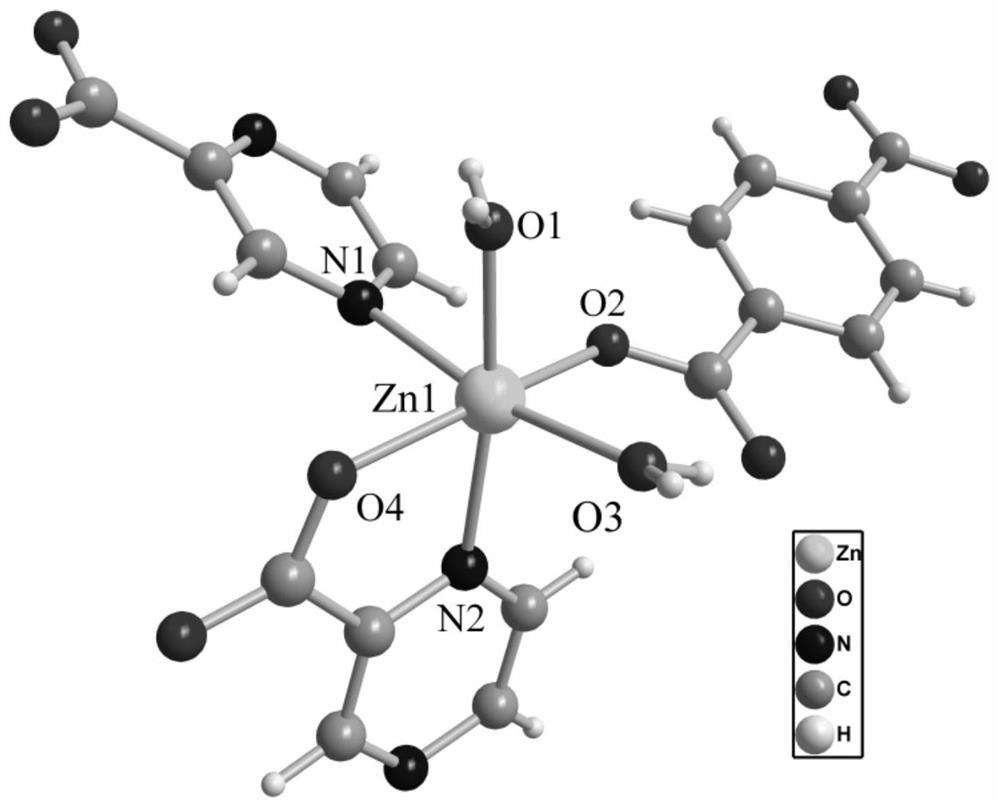

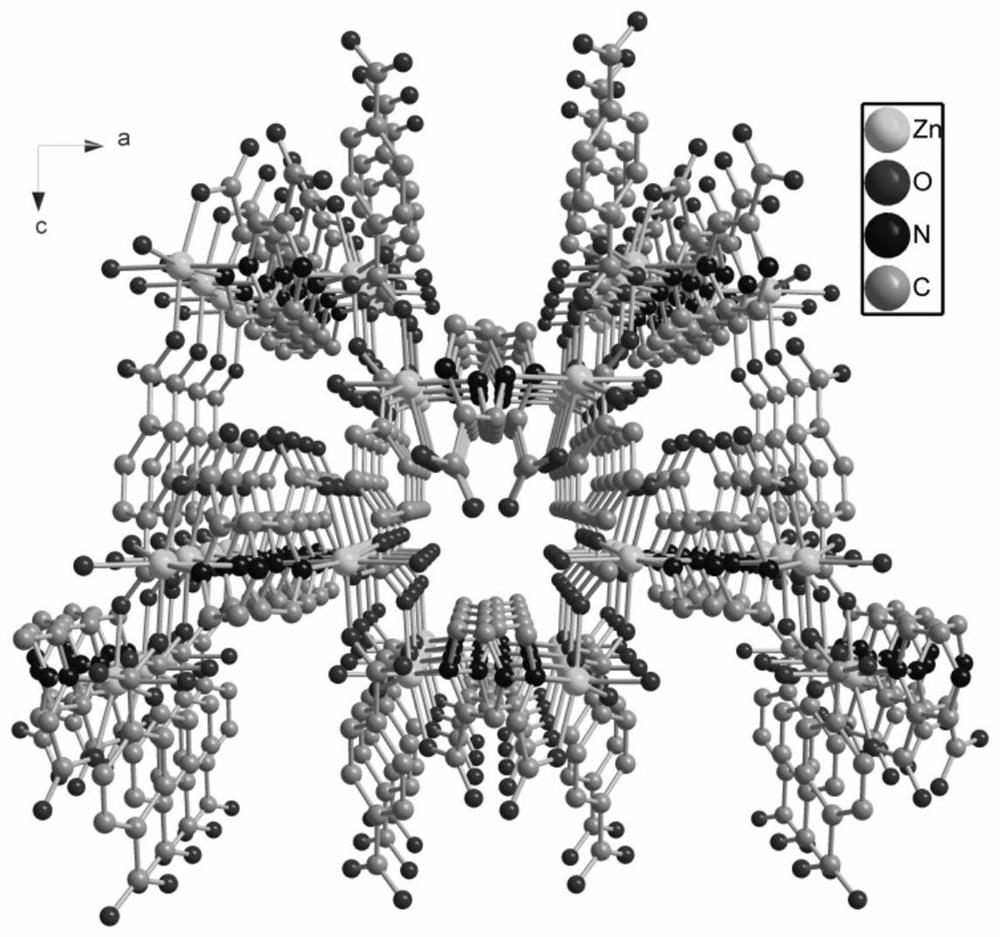

[0025] (1) 0.1363g (1mmol) ZnCl 2 Dissolve in 15mL of distilled water and stir for half an hour.

[0026] (2) Dissolve 0.1241g (1mmol) 2-pyrazinecarboxylic acid, 0.083g (0.5mmol) terephthalic acid and 0.0561g (1mmol) KOH into 15mL of analytically pure N,N-dimethylformamide solution and stir half an hour.

[0027] (3) Mix the solution obtained in step (1) and step (2), and after stirring evenly, transfer to two 25mL stainless steel reaction kettles with polytetrafluoroethylene lining; Reaction under the conditions for five days, program cooling to room temperature to obtain colorless massive crystals, washed with distilled water, after vacuum drying to obtain the target product, yield 0.098g, yield is about 72% (based on ZnCl 2 ).

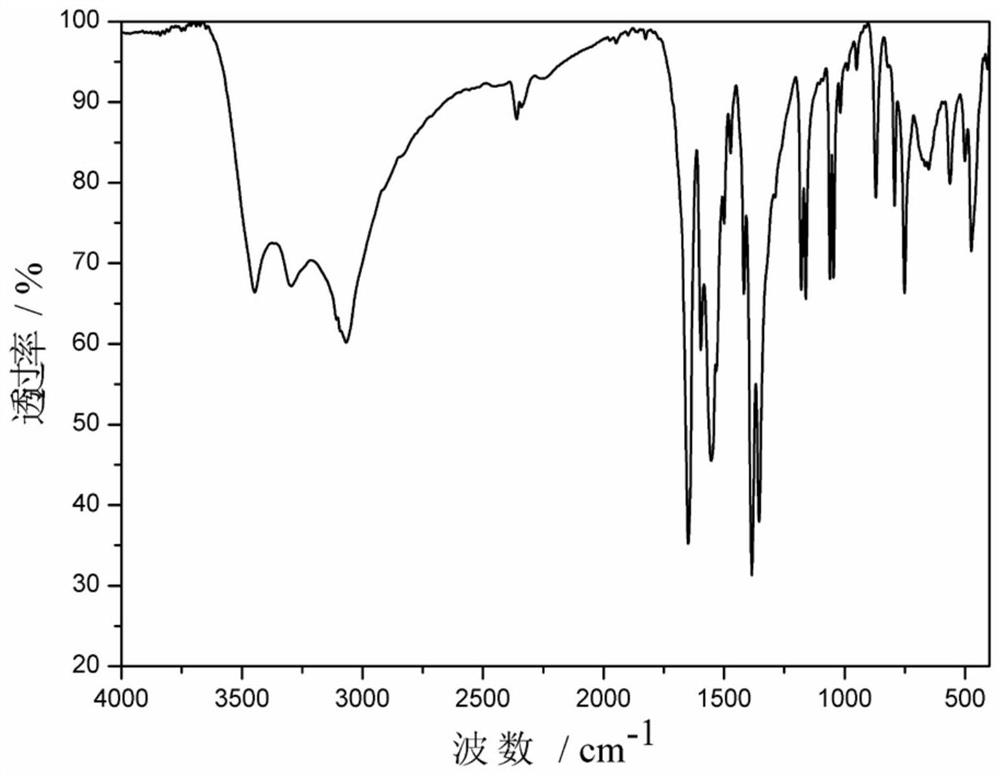

[0028] (4) Weigh 0.10g step (3) Zn-MOF material crystal and immerse it to a concentration of 1×10 -3 mol / L FeCl 3 in the aqueous solution for 24 hours, then filtered and dried at room temperature to obtain the metal ion conjugate Fe of Zn-MOF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com