Long-term self-snow-melting method and system for road in winter

A self-melting snow and road technology, applied to roads, roads, pavement details, etc., can solve the problems of bridge pavement life reduction, road repair cost increase, snow melting and other problems, and achieve the effect of easy realization, simple construction and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

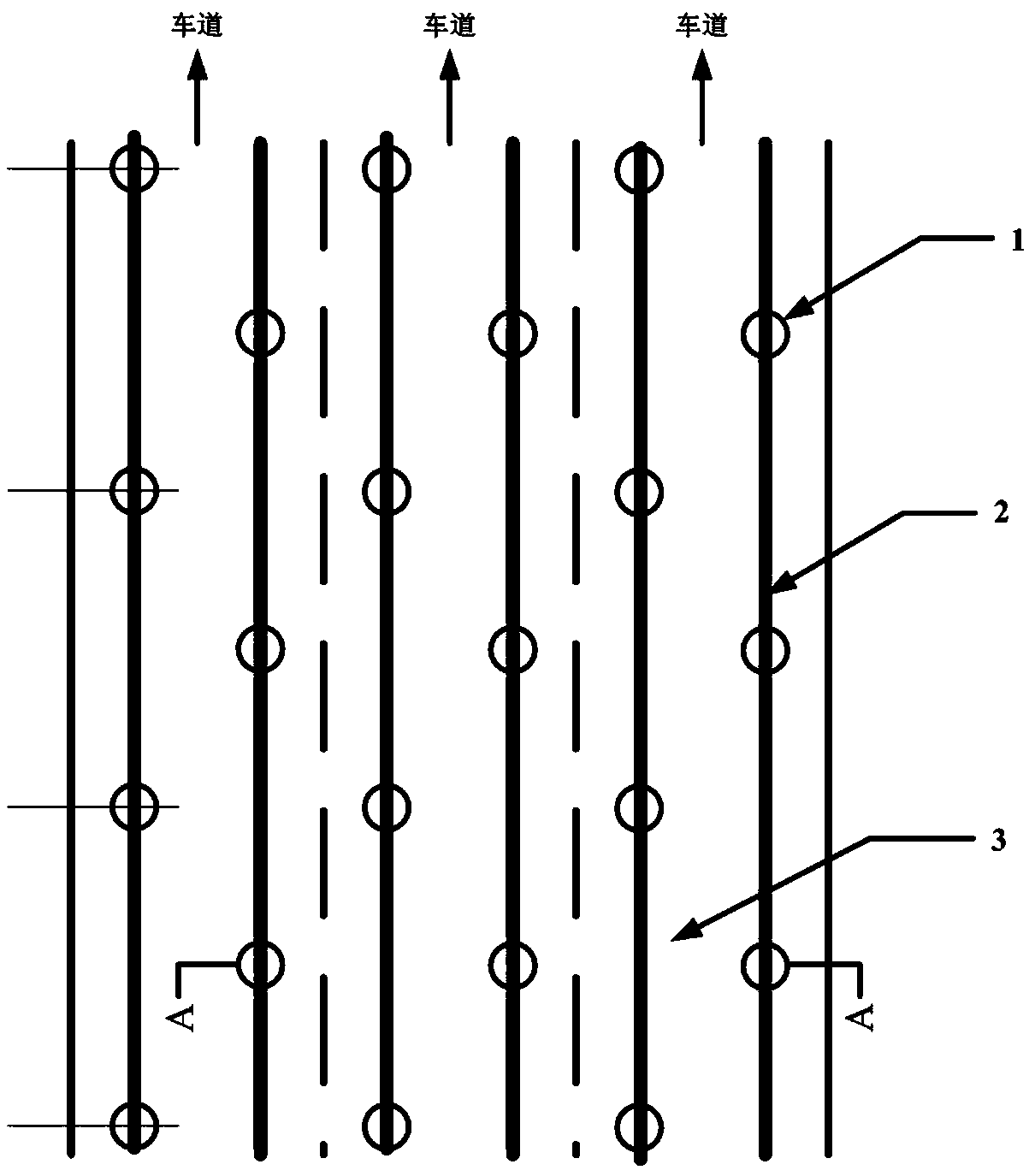

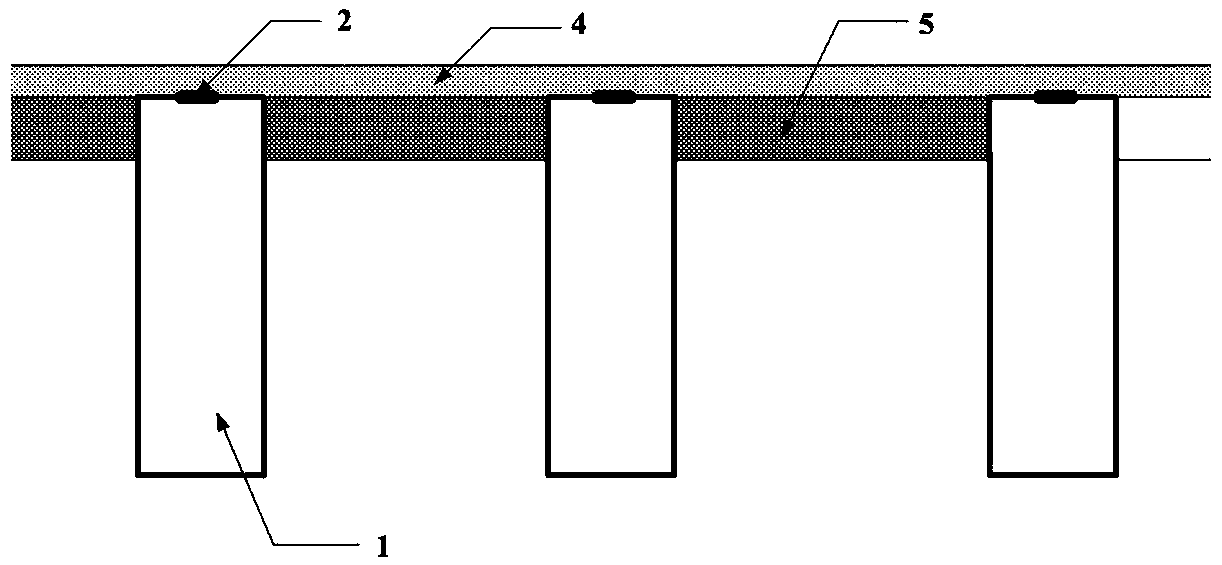

[0016] see figure 1 , figure 2 , the long-term self-melting snow method for roads in winter in the present invention, the realization process is as follows: heat transfer shafts are arranged under the asphalt road surface or concrete road surface, and the heat transfer shafts are arranged at equal intervals under the road surface on both sides of each lane of the road. The heat transfer aluminum strips are longitudinally arranged, and the heat transfer aluminum strips are fixedly connected with the well cover of the heat transfer shaft with bolts.

[0017] The well bottom and the well wall of the heat transfer shaft are isolated from the soil with waterproof and heat-conducting materials to prevent groundwater from seeping in. The well bottom and the well wall are made of concrete, and the well head and well cover are made of cast iron.

Embodiment 2

[0019] see figure 1 , figure 2 , The long-term self-melting snow method for roads in winter in this embodiment is different from Embodiment 1 in that: the depth of the heat transfer shaft is not less than 5 meters, and the distance between the wells is not greater than 10 meters.

Embodiment 3

[0021] see figure 1 , figure 2 , The long-term self-melting snow method for roads in winter in this embodiment is different from Embodiment 1 or Embodiment 2 in that: the width of the heat transfer aluminum strip is not less than 10 cm, and the thickness is not less than 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com