Assembly energy dissipation and vibration reduction filling wall board structure

A filling wall and prefabricated technology, applied to walls, anti-seismic, building components, etc., can solve problems such as too much contribution to lateral stiffness, easy damage to wall panels, disappearance of damping and anti-seismic effects, etc., to achieve good energy dissipation and shock absorption effects, Waterproof and anti-seepage effect is good, and the effect of improving energy consumption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

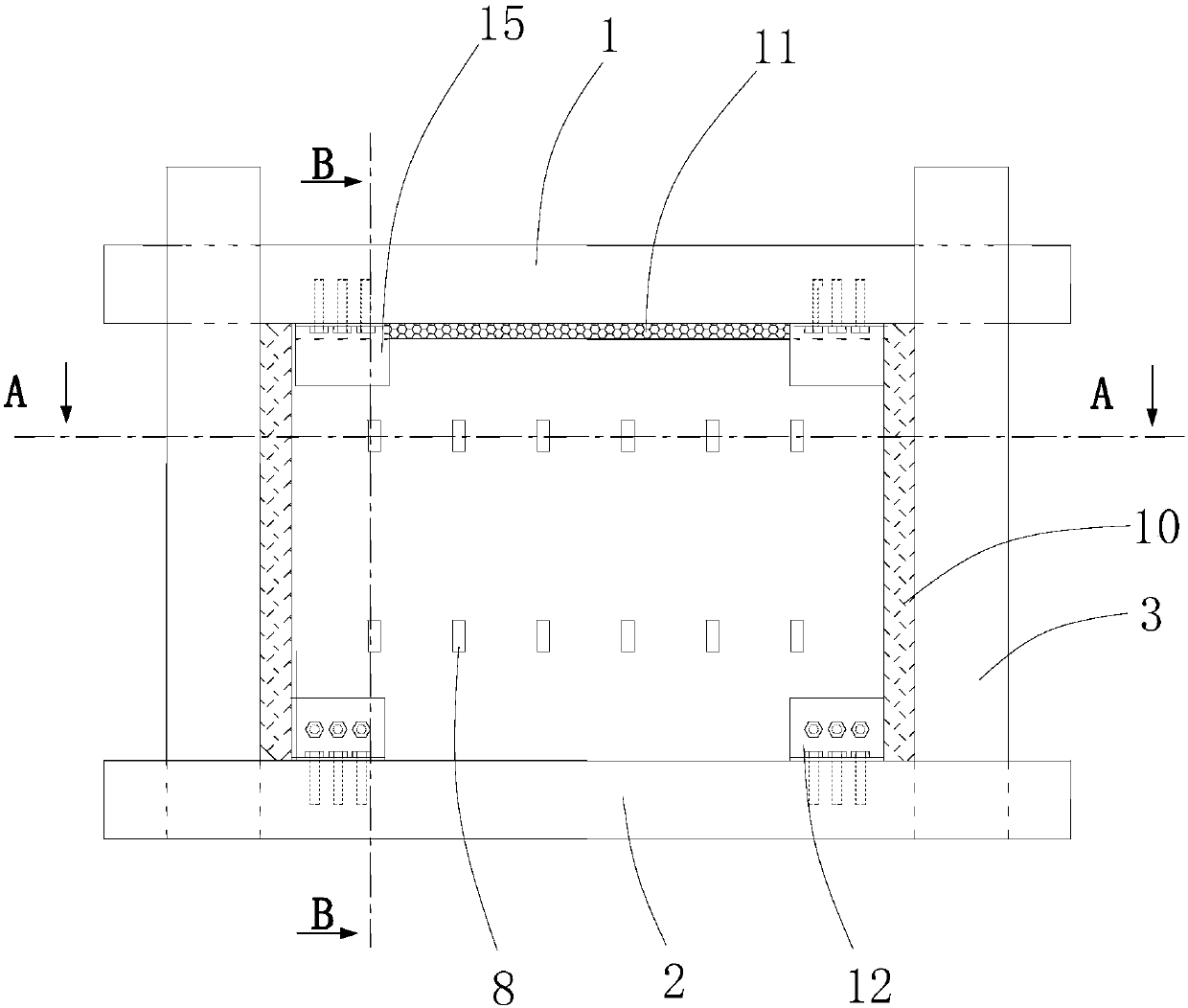

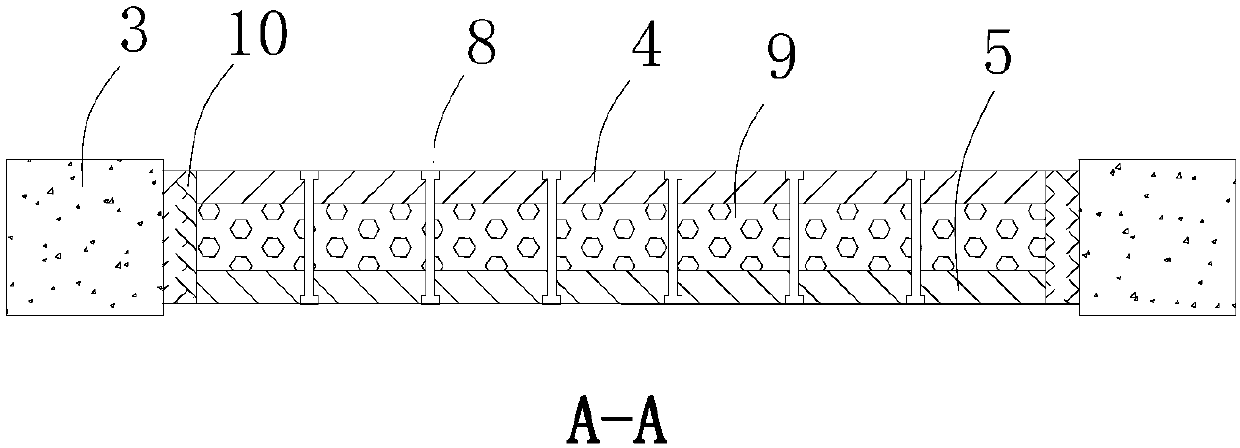

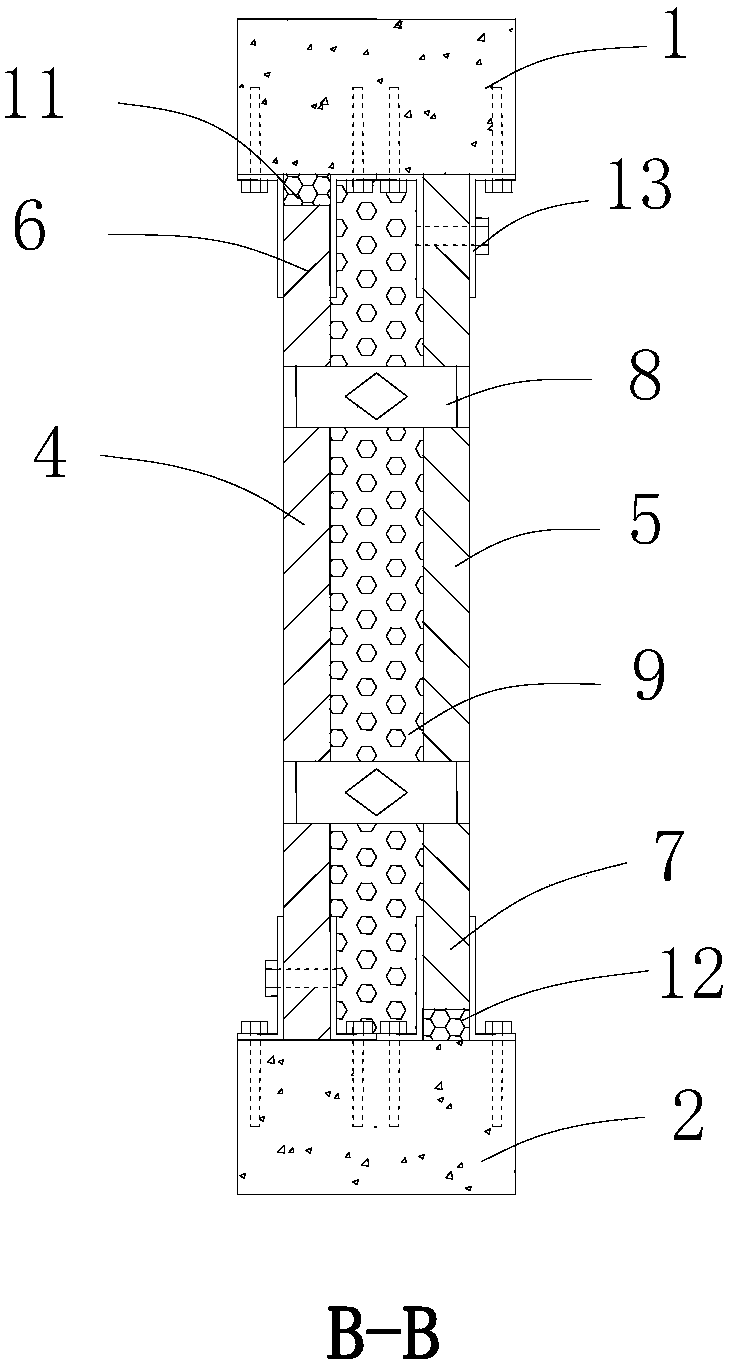

[0049] This embodiment provides an assembled energy-dissipating and shock-absorbing filling wall panel structure, such as figure 1 -9, wherein the wall panel structure is located inside the frame surrounded by the upper frame beam 1, the lower frame beam 2, and the frame column 3, which includes the first vertical plate 4, the second vertical plate 5, and the first guide groove 6. Second guide groove 7, energy-dissipating anchor 8, waterproof insulation layer 9, structural joint 10, upper sliding joint 11, lower sliding joint 12, fixing piece 13, L-shaped angle steel 14, L-shaped guide plate 15.

[0050] Among them, the span of the frame is 4200mm, the floor height is 3300mm, the section size of the frame column is 500mm×500mm, the section size of the frame beam is 300mm×500mm; the concrete strength grade is C30; -2010) and "Code for Seismic Design of Buildings" (GB50011-2010).

[0051] Such as figure 1 -3, the fixed end of the first vertical plate 4 is fixedly connected to ...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is that, as Figure 10 As shown in -12, the energy-dissipating anchors 21 in this embodiment are three rows of steel rods vertically passing through the waterproof and thermal insulation layer. The number of steel rods in each row is 7, which are evenly arranged, and there is a ring in the middle of the steel rods groove, and the groove bottom of the groove is arc-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com