External-circulation cooling system for self-adaptation thrust bearing of pump storage group

A pumped storage unit, external circulation cooling technology, applied in bearing cooling, hydroelectric power generation, bearing components, etc., can solve the problem of increasing the vibration and noise of the bearing cooling system, failing to increase the cooling capacity, and reducing the service life of the bearing cooling system and other problems to achieve the effect of continuous and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

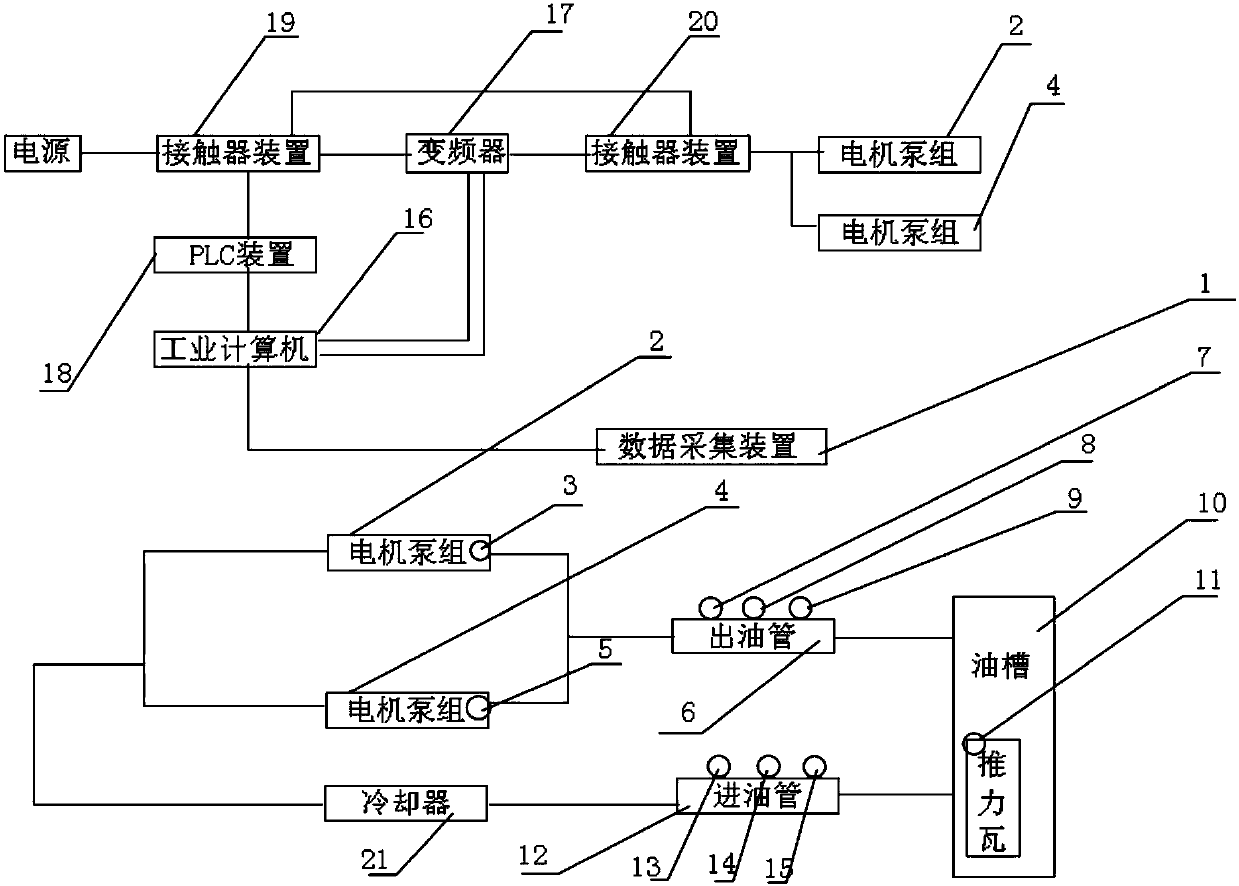

[0010] Such as figure 1 As shown, an adaptive thrust bearing external circulation cooling system of a pumped storage unit includes an industrial computer, a PLC device, a data acquisition device, a contactor, a temperature sensor, a pressure sensor, a flow sensor, a frequency converter, a motor pump set, a cooler, Oil inlet pipe, oil outlet pipe.

[0011] Such as figure 1 As shown, an adaptive thrust bearing external circulation cooling system for a pumped storage unit includes an industrial computer, a PLC device, a data acquisition device, a contactor, a temperature sensor, a pressure sensor, a flow sensor, a frequency converter, a motor pump set, and a cooler , oil inlet pipeline, oil outlet pipeline; NI-CompactRIO-910X data acquisition device 1 measures the temperature of the first SIMOTICS-GP motor pump group 2 through the Pt100 temperature sensor 3 installed on the first SIMOTICS-GP motor pump group 2 Temperature, measure the temperature of the second SIMOTICS-GP motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com