Flame recognition system for aeroengine combustor

A technology for aero-engine and flame recognition, which is applied in the field of flame recognition system of aero-engine combustors, can solve problems such as slow speed and inaccurate results, and achieve the effects of fast speed, expanded application fields, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

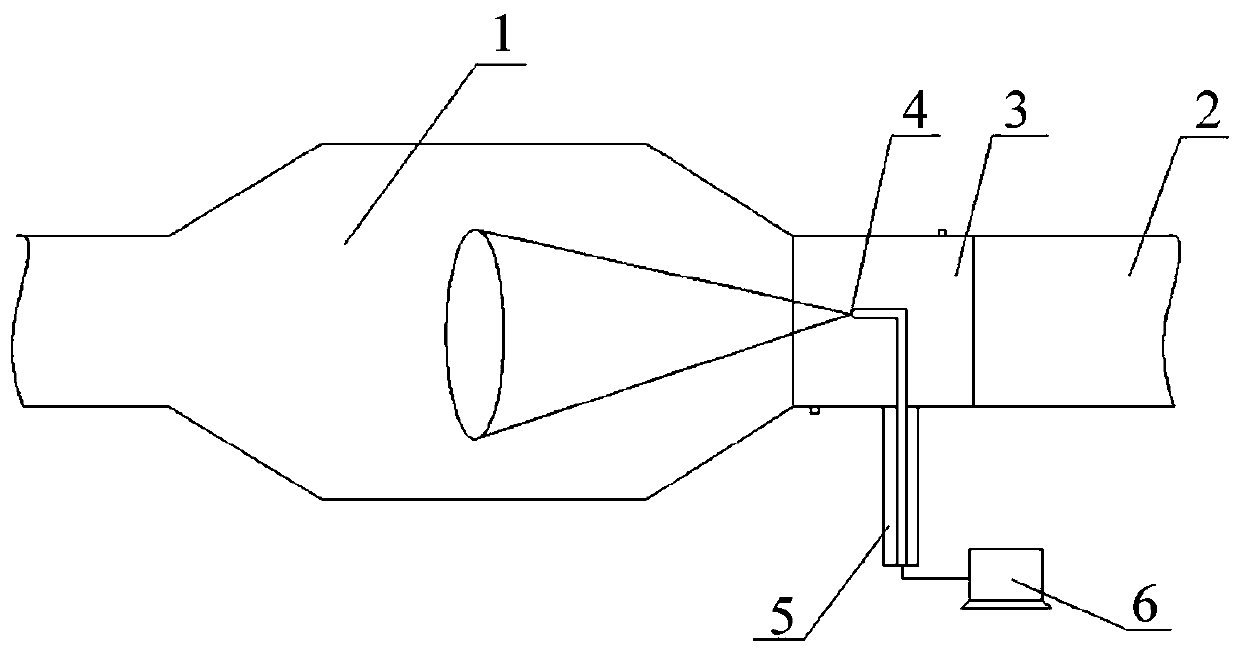

[0025] refer to figure 1 , the preferred embodiment of the present invention provides a flame identification system for aero-engine combustors, which is mainly applied to ignition / flame-out tests of single-pipe / single-head or full-ring combustors. Preferably, the combustor 1 is a single tube combustor or a full ring combustor structure.

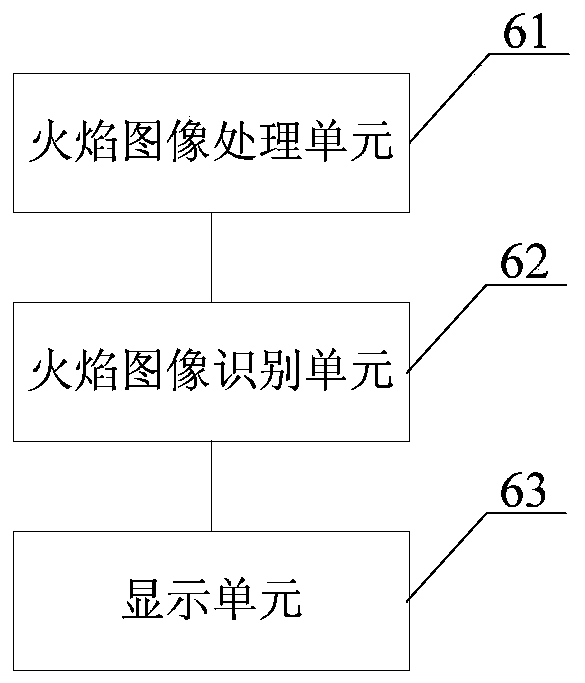

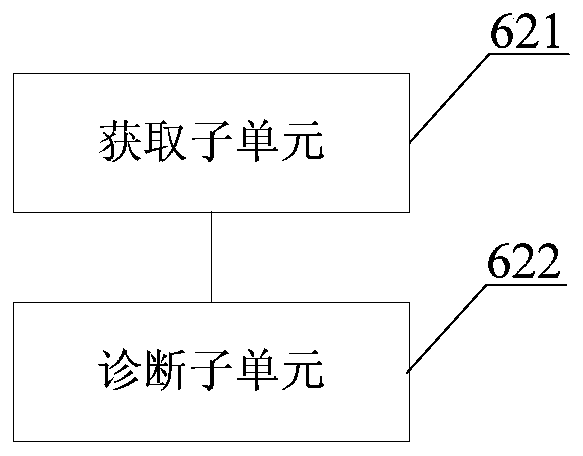

[0026] The present invention is used for the flame recognition system of aeroengine combustor, comprises combustion chamber 1 and exhaust section 2, is connected with the flame observation transfer section 3 that communicates with both between combustion chamber 1 and exhaust section 2, and flame observation transfer section A high-temperature refraction len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com