Integral type blasting operation safety protective cover and manufacturing method thereof

A technology of safety protection and production method, which is applied in the direction of blasting, etc., can solve the problems of easy generation of flying stones, the impact on the personal safety of construction workers, surrounding residents, and pedestrians, and achieve the effect of high bearing capacity and reduced internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

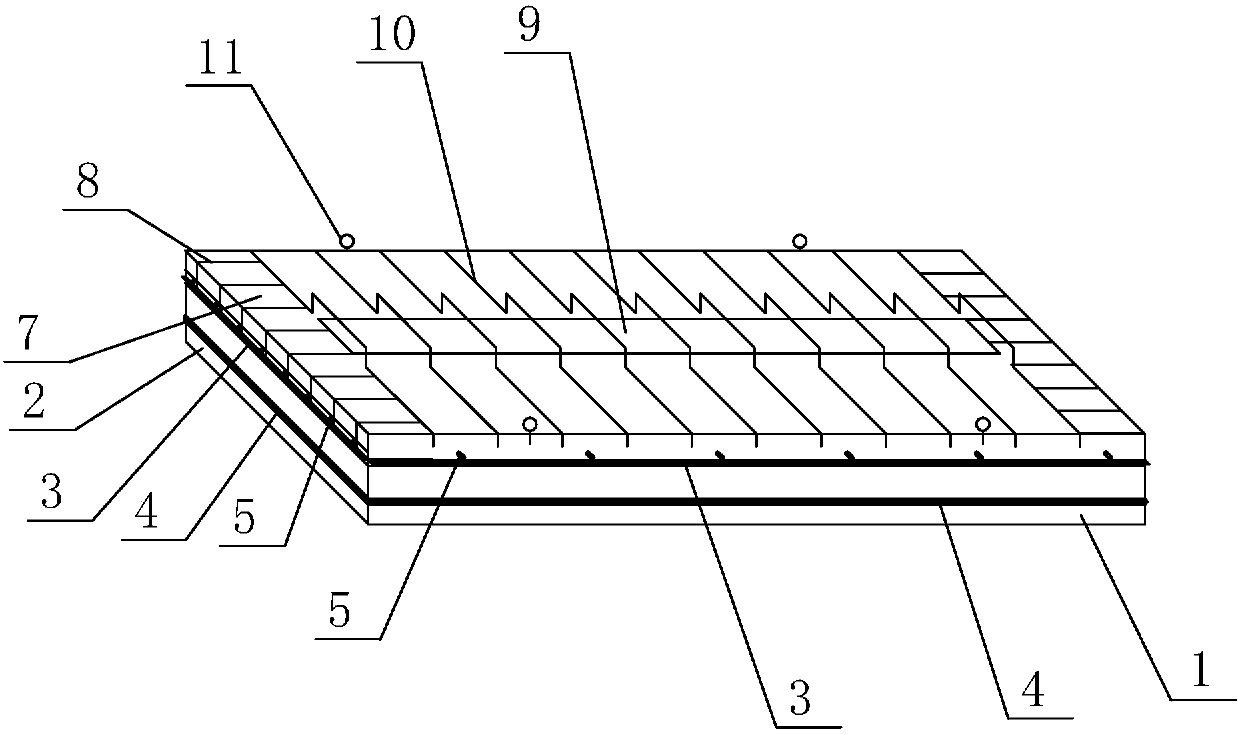

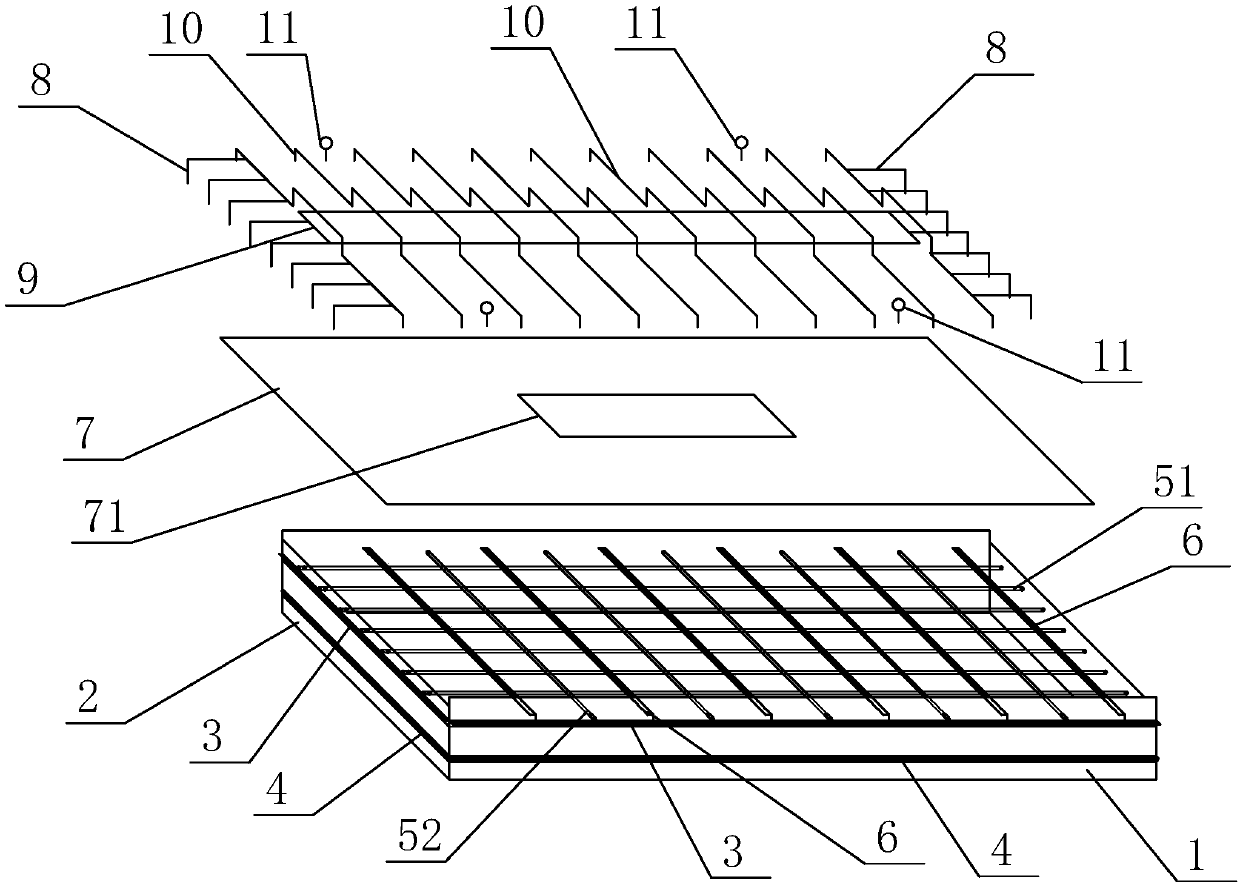

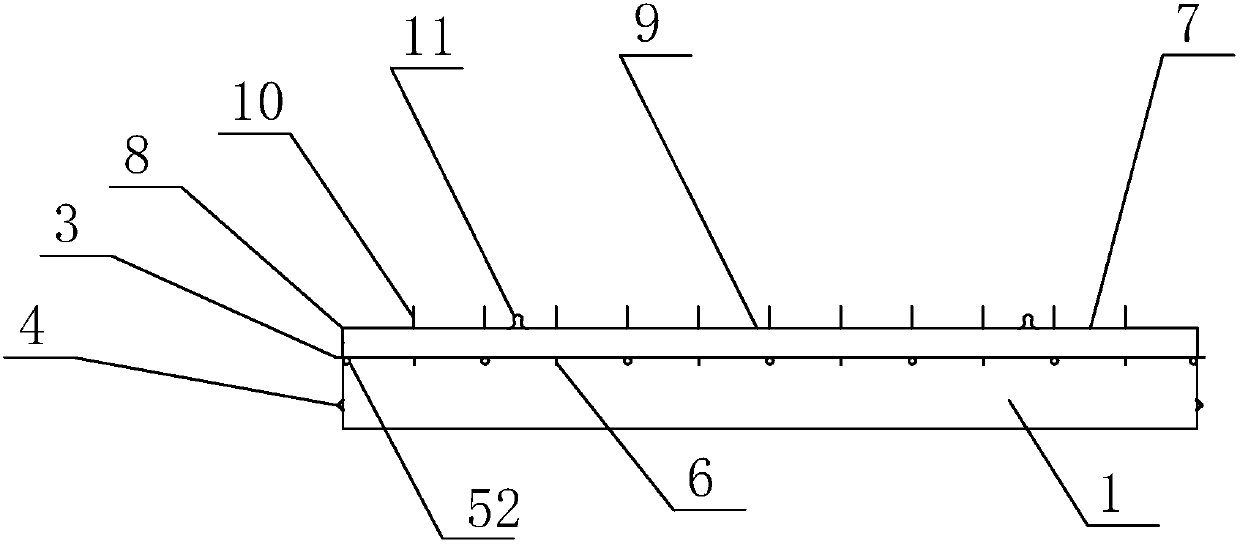

[0044] An integral blasting operation safety shield, such as Figure 1~Figure 4 As shown, the integral blasting operation protective cover includes the peripheral structure of the safety protective cover, a cover plate 7, a hole cover plate 9, a protective rib 10 and a suspension ring 11;

[0045] The peripheral structure is welded by two longitudinal steel plates 1 and two transverse steel plates 2 to form a rectangular four-sided side with a flat bottom, the adjacent two sides are respectively the longitudinal steel plates 1 and the transverse steel plates 2, and the longitudinal steel plates 1 The height of the steel plate 2 is greater than that of the horizontal steel plate 2, and the purpose is to form lateral air wave exhaust holes at both ends of the horizontal direction, so as to reduce the internal pressure of the protective shed. Generally, the height of the longitudinal steel plate 1 is 150mm-250mm higher than the height of the transverse steel plate 2 .

[0046]On...

Embodiment 2

[0055] A manufacturing method of an integral blasting operation safety cover is the manufacturing method of an integral blasting operation safety cover described in Embodiment 1, which includes the following steps:

[0056] A. Welding vertical and horizontal steel plates to form the peripheral structure of the safety shield: the longitudinal steel plate 1 and the transverse steel plate 2 are welded to form the peripheral structure of the safety shield, and the joint position of the two is required to be fully welded.

[0057] B. Weld the upper and lower layers of reinforcing ribs: the upper reinforcing rib 3 and the lower reinforcing rib 4 are welded on the longitudinal steel plate 1 and the transverse steel plate 2 according to the design drawing; the upper reinforcing rib 3 and the lower reinforcing rib 4 are all adopted in specifications L50*50 *4 For the equilateral angle steel, one of the equilateral sides of the upper reinforcing rib 3 is bonded to the horizontal and vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com