A kind of lithium-ion battery high-nickel ternary material and preparation method thereof

A high-nickel ternary material and lithium-ion battery technology, applied in electrical components, battery electrodes, secondary batteries, etc., can solve the problems of capacity loss, poor performance of large ball rate, etc., achieve high residual alkali on the surface, reduce electrochemical Performance difference, effect of reducing surface residual alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

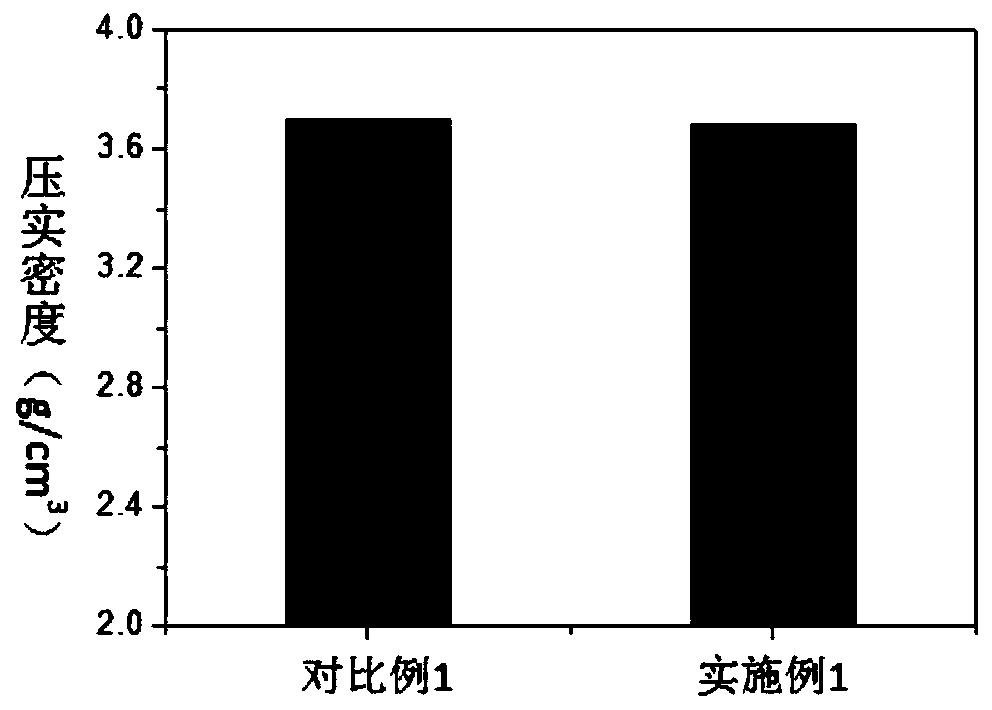

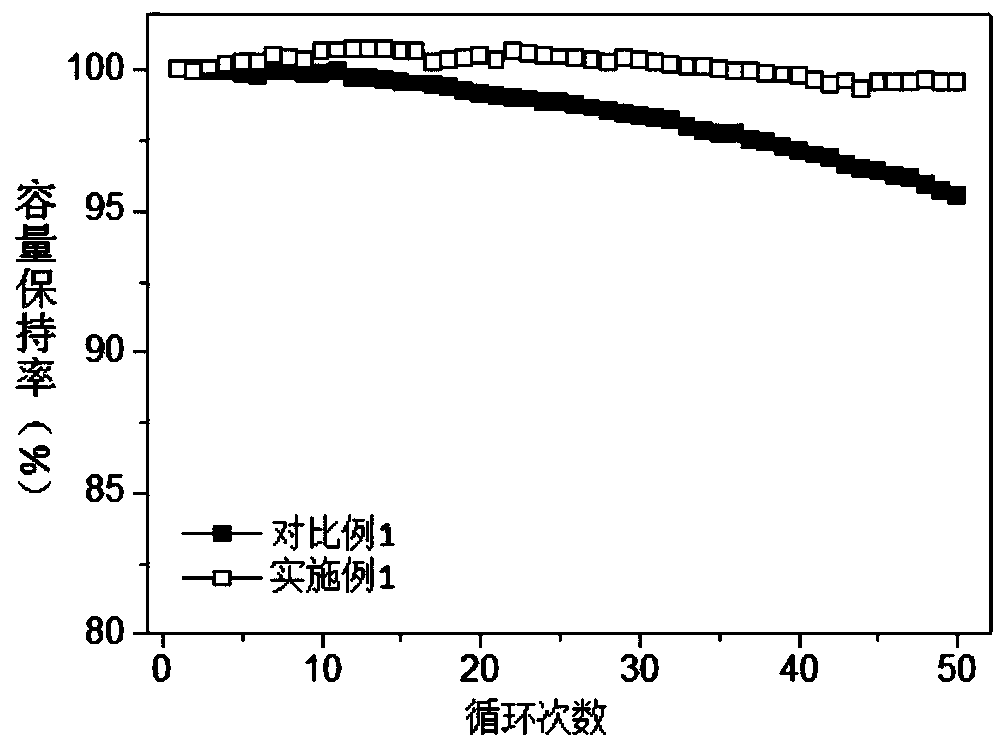

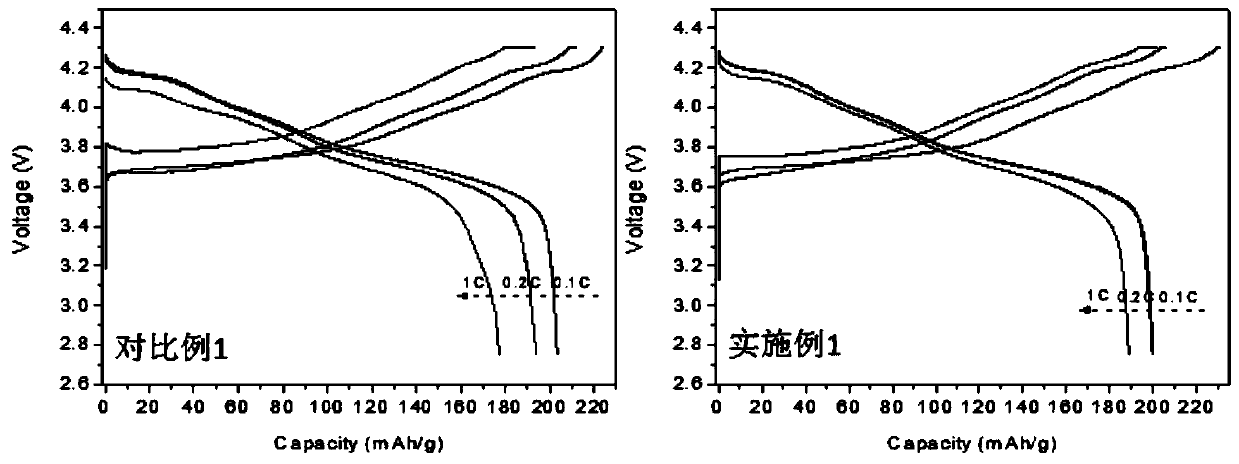

[0028] A high-nickel ternary material for a lithium ion battery, comprising fast ion conductor coated particles and nano-alumina coated particles, the fast ion conductor coated particle includes a large grain core and a fast ion conductor layer, the nano-alumina coated particle Particles include a small particle core and a nano-alumina layer; fast ion conductor coated particles and nano-alumina coated particles are evenly dispersed, the fast ion conductor layer is coated on the outside of the large particle core, and the nano-alumina layer is coated on the outside of the small particle core; The conductor layer is lithium lanthanum titanate, and the large and small cores are high-nickel ternary materials with the same chemical composition;

[0029] Among them, the chemical composition of the large grain core and the small grain core is LiNi 0.85 co 0.1 mn 0.05 o 2 , the particle size of the large particle core is 18 μm, the particle size of the small particle core is 3 μm, ...

Embodiment 2

[0032] A high-nickel ternary material for a lithium ion battery, comprising fast ion conductor coated particles and nano-alumina coated particles, the fast ion conductor coated particle includes a large grain core and a fast ion conductor layer, the nano-alumina coated particle Particles include a small particle core and a nano-alumina layer; fast ion conductor coated particles and nano-alumina coated particles are evenly dispersed, the fast ion conductor layer is coated on the outside of the large particle core, and the nano-alumina layer is coated on the outside of the small particle core; The conductor layer is lithium lanthanum titanate, and the large grain core and the small grain core are high-nickel ternary materials with the same chemical composition.

[0033] The preparation method of the above-mentioned high-nickel ternary material for a lithium-ion battery comprises the following steps: coating the large grain core with a fast ion conductor to obtain a fast ion condu...

Embodiment 3

[0035] A high-nickel ternary material for a lithium ion battery, comprising fast ion conductor coated particles and nano-alumina coated particles, the fast ion conductor coated particle includes a large grain core and a fast ion conductor layer, the nano-alumina coated particle Particles include a small particle core and a nano-alumina layer; fast ion conductor coated particles and nano-alumina coated particles are evenly dispersed, the fast ion conductor layer is coated on the outside of the large particle core, and the nano-alumina layer is coated on the outside of the small particle core; The conductor layer is lithium lanthanum titanate, and the large and small cores are high-nickel ternary materials with the same chemical composition;

[0036] Among them, the chemical composition of the large grain core and the small grain core is LiNi 0.98 co 0.01 mn 0.01 o 2 , the particle size of the large particle core is 14 μm, the particle size of the small particle core is 5 μm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com